In the context of agricultural and turf spraying applications, there is a big difference between using air-induced nozzles and standard nozzles. Although they may seem similar these different types can significantly impact the effectiveness and efficiency of your sprayer.

The difference between air-induced and standard sprayer nozzles is that air-induced nozzles incorporate air into the droplets they produce by using a venturi effect that pulls air into the nozzle as the liquid passes through, resulting in droplets filled with air. Standard nozzles do not pull air into them, they simply shape and direct the spray pattern.

Air-induced nozzles should be used when drift is a concern or when the label of the pesticide/herbicide you use indicates that you should use one.

There are several different types of air-induced nozzles, and a wide range of droplet sizes they produce. Let’s get into the distinct characteristics, advantages, and when you should use each type of nozzle.

Air-Induced Nozzles

Air-induced nozzles, also known as air-induction nozzles or venturi nozzles, are designed to draw air into the spray droplets as they are dispersed from the nozzle. This results in larger droplets.

These nozzles are effective at reducing drift potential. The larger droplets are less susceptible to being blown off-target by wind. A chemical that drifts off target can potentially damage plants, lawns, or animals adjacent to the field you are spraying.

There are certain chemicals that will require the use of a certain droplet size when being applied. The label on the product will indicate the range and percentage of acceptable droplet size that your sprayer nozzle must produce. The guideline on the product label must be followed or it can result in a violation of local law.

One significant product in the agricultural world is Dicamba. The use of this herbicide is regulated and there are certain times of the year that it can be used and specific droplet size requirements. We will take a look at this more closely in a moment.

Standard Nozzles

Standard nozzles, often referred to as conventional nozzles, produce a spray pattern without incorporating air into the droplets.

Standard/conventional nozzles generate finer droplets than their air-induction counterparts, which can result in more thorough and even coverage on foliage and target surfaces.

These nozzles are preferable in situations where fine droplets are desirable and drift is less of a concern. They are specifically used with contact herbicides that require good coverage of the plant tissue to work effectively.

Droplet Size Comparison

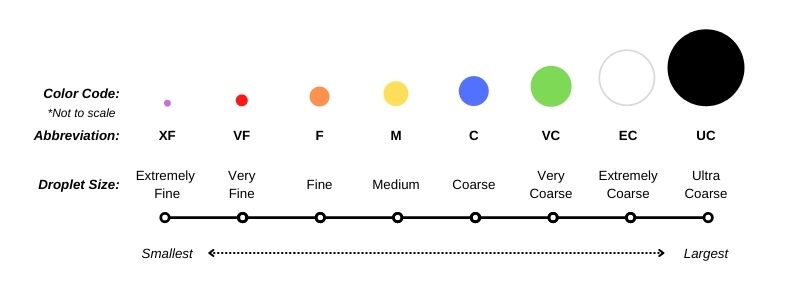

Again, droplet size is the main difference between these two nozzle types. When we talk about droplet size, it might seem a bit arbitrary, but there is a lot of nuance behind it. In terms of sprayer nozzles, droplets are measured in microns. They are classified based on their size from extremely fine (smallest) up to ultra coarse (largest).

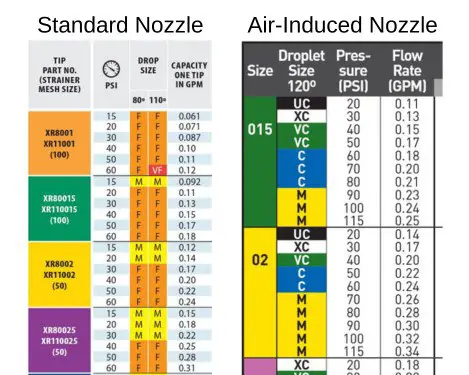

Standard Nozzle vs. Air-Inducted Nozzle Droplet Size Comparision

The droplet size a nozzle produces is detailed in the spray nozzle chart for that particular brand and type of nozzle. Droplet size is affected by the pressure that the sprayer is operating. Typically, the higher the pressure the smaller the average size of the droplets produced by a given nozzle.

This is why it is important to read the nozzle chart. It will show the operating pressure range of each nozzle and what size the majority of the droplets will be at each pressure. Below you can see the scale used to categorize different droplet sizes.

This is critical to understand because a herbicide label may tell you to use a spray tip that produces an ultra-coarse droplet. Your spray nozzle might produce ultra-coarse droplets at 30-40 psi but at 50 and above the droplets might be reduced to extremely coarse or very coarse. In this case, operating your sprayer at 50 psi or higher would be a violation of the label, even though you are using a spray tip that is can develop the correct droplet size.

When to Use Dual Fan Air-Induced Nozzles

With larger droplets, there are some challenges. As the average droplet size increases the amount of overall droplets is reduced, assuming the flow capacity of the nozzle and pressure remain constant. This can lead to less surface area getting covered by the liquid.

One method to combat this is to use a dual fan nozzle. Dual fan nozzles split the spray pattern into two separate fans. Typically, one is angled slightly forward, and one slightly toward the rear. This does not apply any more liquid than a single fan nozzle of the same size, but it hits the plant from two directions. This can help the fluid to reach areas of the plant tissue that might get missed from a single fan.

Herbicide/Pesticide Label Instructions

Following the label guidelines are vital. Users are legally obligated to follow the instructions on the pesticide label. Failing to do so can potentially result in legal penalties, including fines or other legal actions.

As mentioned earlier in this article, Dicamba is a herbicide that is regulated by the EPA. They have cut-off dates that restrict applying a Dicamba-based product, such as XtediMax or Engenia, after that day. These regulations vary from state to state.

The droplet size required when spraying a Dicamba product is also regulated. The specific brand of product you use will typically provide the specific spray tips from several manufacturers approved for use with the product as well as the PSI range that they need to be operated at.

When to Use Air-Induced Nozzles: The Bottom Line

Air-induced nozzles and standard spray tips may seem similar, but the potential impact of using one or the other is significant. Using the wrong one can affect the effectiveness of the product you are spraying, pose a threat to adjacent plant life, or even be a violation of the law.

The bottom line is that the label will provide the answer to what type of tip you should use. From there you can consider other factors like pressure, speed, crop type, etc. For more information on different sprayer nozzle types and how to use a sprayer nozzle chart, be sure to review these resources below: