If you are in the market for a sprayer, whether you build or buy you will naturally ask the question, “How do I choose a sprayer pump?” Understanding the different types of sprayer pumps as well as the different sprayer types is pivotal. Whether you’re a contractor, pest control pro, or property manager, this guide will arm you with the knowledge you need.

Let’s get started, so you can confidently select the sprayer pump that suits your project’s needs.

Key Takeaways

- Learn the fundamentals of selecting the ideal pump for your spraying needs.

- Discover what makes certain sprayer pumps the best choice for different applications.

- Grasp the significance of matching pump types to specific sprayer models.

- Gain insights on balancing cost, performance, and maintenance requirements.

- Acquire the knowledge to distinguish which features are crucial for your tasks.

- Empower yourself to make informed decisions for residential or commercial spraying.

Understanding Sprayer Pumps and Their Importance

Sprayer pumps are at the heart of effective and efficient liquid applications. From backyard gardens to expansive agricultural fields. Understanding the mechanics and operation of these pivotal devices is crucial for achieving optimal results. Pumps are not merely supplementary components; they are integral to the performance and reliability of your sprayer.

Sprayer pumps, be they used in a lightweight handheld device or a robust ag sprayer pump, are engineered to transfer varying volumes of liquid at specific pressure levels. This is essential for ensuring that your pesticides, fertilizers, or herbicides are evenly distributed across the target area, providing full coverage and minimizing waste.

The principle behind a pump’s operation is simple yet ingenious, involving the conversion of mechanical energy into fluid flow. This fluid dynamic is the driving force behind any spraying task. However, not all pumps are created equal.

The nature of your spraying task — including the size of the area and the type of liquid you wish to dispense — dictates the pump best suited to your needs. While a small, battery-powered sprayer might suffice for a modest garden, a larger, engine-driven pump is a prerequisite for the vast expanses of commercial farms.

Here are some key considerations when delving into the world of sprayer pumps:

- Pump Type: Different types of pumps—centrifugal, diaphragm, piston, etc.—have varied capabilities and are fit for specific functions.

- Pressure Requirements: The pressure output of your pump directly impacts the spray pattern and droplet size—crucial factors in fertilizer and pesticide application.

- Flow Rate: A pump’s flow rate, often measured in gallons per minute (GPM), influences how quickly you can cover a given area.

- Material Compatibility: The chemicals you intend to spray may require materials within the pump that are resistant to corrosion or decay.

Selecting the correct pump is not just a technicality but a crucial decision for the efficiency and effectiveness of your sprayer. A mismatch between a pump and application can lead to inadequate coverage, wasted product, and even damage to the pump itself due to incompatible chemicals or excessive wear.

The quest for the best sprayer pump to suit your needs is multifaceted, encompassing not only the technical specifications but also considerations of durability, ease of maintenance, and cost-effectiveness. So if you need help selecting the best pump for your job, read on.

How Do I Choose a Sprayer Pump?

When contemplating the question, “How do I choose a sprayer pump?” understanding your specific needs is crucial. The right pump for your lawn, crop, tree sprayer, or other spraying equipment can make all the difference in your maintenance tasks. Pump selection requires careful analysis of several factors.

Begin with an assessment of the sprayer pump’s intended purpose. This includes considering the size of the area to be treated and the type of liquid solution you will be using. Here is a list of things to consider:

- Pump Type

- Size (Flowrate)

- Pressure

- Material of Construction

- Drive Type

- Cost

The first and most important thing to consider is the type of pump that will suit your situation. There are many different types of pumps and they are not created equal. For example: the best type of pump for spraying large crop fields will not be the same as the best type of pump for spraying trees. The type of pump needed for applying fertilizer on a lawn will not be the same as the pump needed to spray roadsides.

Once you identify the right type of pump for your needs, you can then determine the other aspects. The pump size (flow rate), pressure, the best material to suit you, and the best drive option will all depend on specific needs and preferences.

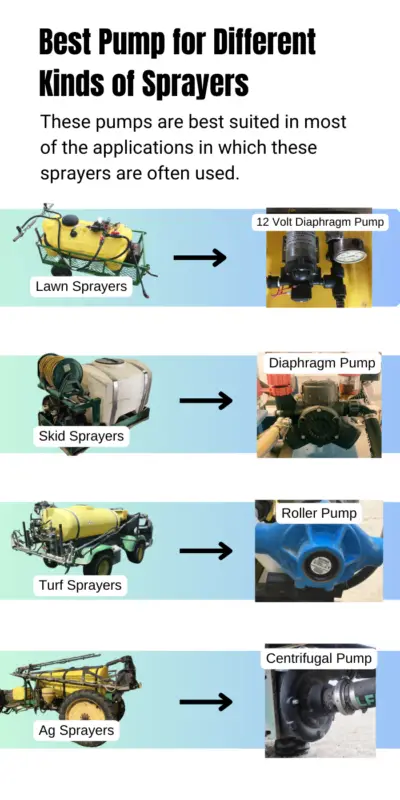

Let’s examine some common spraying applications and the pump types that work best. We can also examine the pump size and pressures needed for these applications as well.

What Type of Pump is Best for a Sprayer

Choosing the best sprayer pump will depend on various conditions such as the type of chemicals used, the spraying area, how you will spray, and the desired operating pressure.

Lawn care applications likely won’t need a pump that produces the same volume that pumps on large agricultural sprayers. The size of the sprayer is smaller, requiring much less flow per minute to cover the area.

The pressure needed may be higher. When spot spraying an area, higher pressure gives the sprayer more reach, meaning the liquid can be sprayed a greater distance. With a boom sprayer, the distance it can spray is not important. Instead, consistency and a wide span of coverage area are more valued.

12-volt diaphragm pumps are very versatile low-volume pumps. They are an affordable choice for lawn sprayers that don’t require more than a few gallons per minute. If the rate needed is greater than this, we would look to a roller pump or medium-pressure diaphragm pump.

Although a roller pump can potentially produce higher flow rates, a medium-pressure diaphragm pump will offer higher pressures. They are more versatile and handle a wider array of products compared to the roller pump. Giving you the ability to spray trees and pump viscous or gritty fertilizers.

A medium-pressure diaphragm pump does require more service and maintenance, however. They also tend to be more expensive. A roller pump would be a simpler option for a beginner.

As you can see there isn’t always a one-size answer. The thought process requires you to consider many factors and make an informed choice.

By the way, If you are still unsure after reading this, contact me and I would be happy to provide some guidance in selecting a pump or a sprayer that will suit your needs!

Exploring the Different Types of Sprayer Pumps

When it comes to agricultural and lawn care, ensuring that you have the best sprayer pump for your specific needs is critical to the success of your spraying tasks. Various types of sprayer pumps offer different functionalities and benefits, making them suitable for a range of applications.

I have a guide that describes the different sprayer pump types in detail. Be sure to read that for more information on the specifics of each sprayer pump. Here are the basic types and their key characteristics:

Diaphragm Pumps

Diaphragm pumps are known for handling viscous liquids and producing medium-high pressures. They’re compatible with a variety of chemicals and produce the required flow and pressure for long-range applications like turf and tree spraying.

Cons: Require routine maintenance and new diaphragms. More expensive relative to other types.

Piston Pumps

This pump design is known for precision and is ideal for situations involving high-pressure spraying. These pumps are used for long-distance spraying and high-pressure applications. Commonly used in high-pressure cleaning applications.

Cons: Relatively expensive. Potentially dangerous, and requires relief valves and high-pressure plumbing.

Centrifugal Pumps

Centrifugal pumps are the go-to devices for large-volume liquid transfer. They are operating at relatively low pressures. Very common in agricultural settings.

Cons: Limited pressure. Require large horsepower for large volumes. Cannot be run dry.

Roller Pumps

Roller pumps offer a balance of pressure and volume without the complexity of other pump types, making them a favored choice for smaller-scale operations.

Cons: Not suitable for abrasive liquids, shorter life spans.

| Pump Type | Pressure | Volume | Main Uses |

| Diaphragm | High | Medium | Turf and tree spraying, high resistance chemicals |

| Piston | High | Low to Medium | Professional pest control applications |

| Centrifugal | Low to Medium | High | Irrigation, large area fertilization |

| Roller | Medium | Medium to High | Small-scale farming, turf care, garden care |

Armed with this information, we can walk through some more specific scenarios and guide you in selecting the best sprayer pump type.

Best Sprayer Pumps for Residential Use

When it comes to maintaining a pristine lawn or garden, selecting the best sprayer pump becomes an integral part of your property management arsenal.

If you are embarking on the journey of residential lawn and garden maintenance, understanding the balance between efficiency, affordability, and longevity is key in choosing a lawn sprayer pump that meets your specific needs.

You will find that the market presents a variety of sprayer pumps. To make an informed decision, consider not just the purchase price, but also the operational cost, ease of maintenance, and the durability to withstand regular wear and tear.

For those of you prioritizing convenience and minimal physical effort, battery-powered sprayer pumps offer an efficient solution. However, if you are looking at cost-effective options, manual backpack sprayers can be the perfect fit.

For small lawn and garden boom sprayers or spot sprayers, 12-volt diaphragm pumps are typically large enough for these applications, and they are very affordable. Typically less than $200.

Ultimately, the best sprayer pump for residential use is one that aligns with your personal preferences, matches the scope of your lawn or garden, and stays true to your budget without compromising on quality. Weigh your options carefully, and you’re bound to find a lawn sprayer pump that serves you well for many seasons to come.

FYI: You can see a list of the sprayers and equipment that I use in this guide.

Best Sprayer Pumps for Agricultural Boom Sprayers

Agriculture spraying is diverse. From foggers for orchards to self-propelled boom sprayers for large fields. The different methods of dispersing liquid will require different types of pumps to achieve the desired results.

For boom sprayers, the best pump is a centrifugal pump. A centrifugal pump is a low-pressure pump. Boom sprayers are typically operating anywhere from 20-80 psi and many centrifugal pumps can produce this pressure. The flow rate needed for a boom sprayer will vary depending on the boom size, travel speed, and nozzle size.

You can refer to the article I wrote on sizing a pump for a sprayer to learn more about determining the size of the sprayer pump you need.

With higher flow pumps you will need more horsepower. Centrifugal pumps can be driven by just about any motor type you desire. For boom sprayers, PTO and hydraulic drives are most common in agriculture, however, if you want to build a spray rig, a gas-engine-driven centrifugal pump works great.

Farmers know that their equipment must withstand not just the test of time, but also the harshness of the chemicals used in agricultural practices. Materials like polypropylene, cast iron, and stainless steel are typically used for pump housings. These materials offer resilience against corrosive substances while ensuring long-term durability.

A key feature of centrifugal pumps is the mechanical shaft seal. This prevents leaks around the shaft as it turns. This component can wear out over time and if the pump is run dry it can fail quite quickly. Aggressive chemicals and fertilizers are hard on pump seals. Many pump manufacturers offer heavy-duty seals to hold up to the abrasion of agrochemicals/fertilizers.

Using a pump with this seal may be advisable in large-scale crop production wear the sprayer is used to spray potentially thousands of acres in a week. It is also a great idea to have a spare seal on hand for your sprayer pump, if not an entire pump itself. The cost of an extra pump is typically well worth it compared to the cost of downtime for farmers or custom applicators.

Conclusion

Pumps can be intimidating if you are not familiar with them. I hope this guide has helped you understand the differences between different sprayer pump types and what the best pumps are for different applications.