Whether I am spraying with my hand sprayer or boom sprayer, dripping nozzles seem to be a constant battle. Chemicals in the wrong place can cause problems, that’s why eliminating the drip from your sprayer nozzles is important. So what can you do to stop your nozzles from dripping?

To keep your sprayer nozzles on a boom from dripping, install a check valve prior to the nozzle. The check valve will close when your operating pressure drops below a certain level, typically 10 psi, and stop any fluid from dripping out of the spray nozzle tip when you shut off your boom or sprayer.

To keep a nozzle on a spray gun from dripping you can also use a check valve, or you can use a “drip-free” gun. These spray guns have a stem with a seat on the end that runs from the trigger throughout the barrel of the spray wand. This stem and seat keep your nozzle from dripping when the trigger is released. Using this type of spray gun can reduce or eliminate any dripping from your spray nozzle.

Let’s take a look at the different options of check valves available to keep sprayer nozzles from dripping, when to use them, and how to keep them working properly.

Eliminating Dripping Spray Nozzles on Sprayer Booms

If you have a sprayer boom that does not have check valves on the nozzle body you have a couple of different options. You can replace your existing nozzle bodies with bodies that have a built-in check valve or you can add a small check valve that fits inside your existing nozzle body under the nozzle and cap.

Switching to Nozzle Bodies with Check Valves

If you have old nozzle bodies or want to change them out, you can replace them with bodies that have the check valve built-in. Most manufacturers of the ag sprayer components offer a nozzle body with a check valve.

They offer different opening pressures or “cracking pressure”. This is the PSI that will be required to open the valve. When a sprayer pump or section is shut off the system will drop in pressure. When the system pressure drops below the “cracking pressure” of the check valves then they will close.

With most of the nozzle bodies out there, the cracking pressure can be changed by swapping out the check valve cap. Generally, they are color-coded. Here are the different check valve “cracking pressures” offered by Teejet (in PSI):

- 2# – Yellow cap

- 5# – Black cap

- 8# – Black

- 10# – Black

- 15# – Red cap

- 20# – Black

Adding Check Valves to Your Existing Nozzle Body

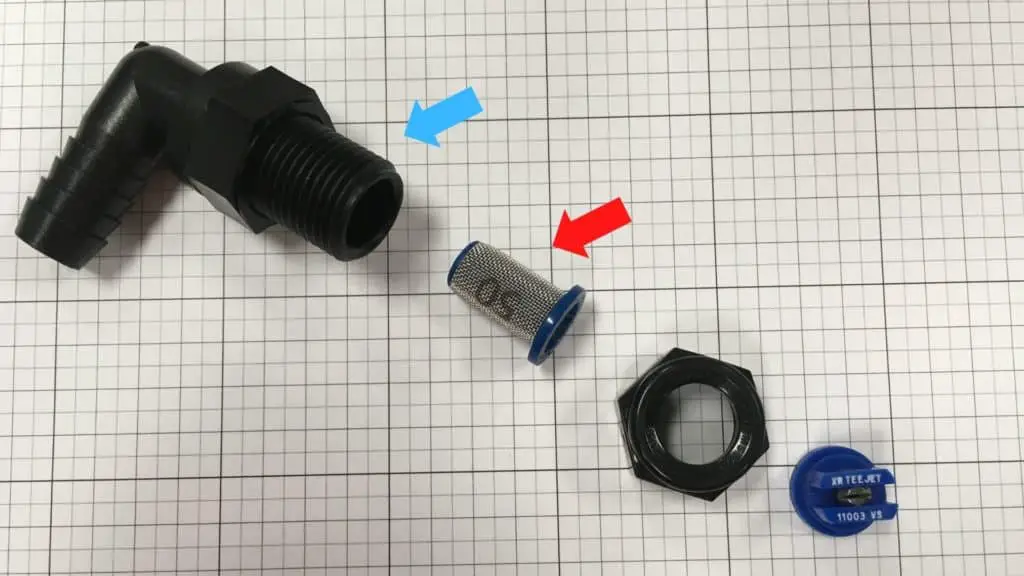

If you don’t want to replace all of your nozzle bodies, you can add a check valve to them. This will work on most simple nozzle body tees and elbows with quick caps or 11/16 nozzle body thread. 11/16 nozzle thread is a somewhat universal thread size that is used on spray wands, nozzle bodies, and other sprayer accessories. This thread with a cap is used to hold sprayer nozzles in place. Typically, a wand or nozzle body with this thread will accommodate a strainer or strainer check valve combination.

You may be using a strainer inside your nozzle body, the check valve will replace the strainer. There are check valve combination strainers available so you can keep your nozzles from plugging. You can find these strainer check valves here. Like the nozzle body check valve version, they come in different cracking pressures.

How do you decide which PSI check valve to use?

Selecting the PSI that will work for your application is pretty straightforward. If you are operating pressure is 15 psi then you won’t want to use a nozzle body check valve that opens at 20 psi. You would need to select a check valve with a cracking pressure lower than your operating psi.

Keep in mind that the check valve will not close until your system pressure or pressure in your hose/boom drops below the cracking pressure. If you are spraying at 40 psi and have an 8-pound check valve, then your nozzle will continue to drip until the pressure in the line drops to 8 psi.

How to Keep Your Check Valves Working Properly

Over time residue can build up on the diaphragms inside the check valve. Eventually, this can cause them to fail and your drip will be back. You can flush the sprayer with fresh water as often as you can to reduce chemical residue. If you have a bad diaphragm it can be replaced.

How to Stop Your Spray Gun From Dripping

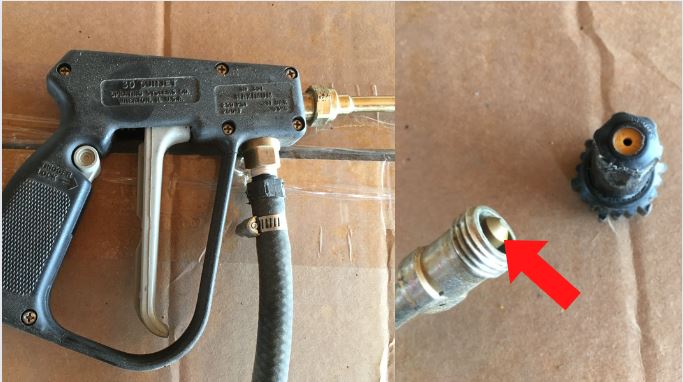

The best way to eliminate a drip from your spray nozzle on a sprayer gun is to replace it with a “drip-free” version. As mentioned at the start of this post, there are sprayer guns available that stop drip when you let go of your trigger. This happens because the shut-off point of the trigger gun is at the tip itself. Puling your trigger opens the valve seat behind the spray tip and when the trigger is released it closes to quickly shut off your spray pattern.

Some spray guns and wands have a check valve in the handle, but any liquid that is in the wand will still drip out after you release the trigger. If you have a long spray wand this can be significant. You can add a check valve at the end of the wand to fix this. Depending on your spray gun/wand combination there are a couple of ways to accomplish this.

If the end of your wand has an 11/16 nozzle body thread, then a check valve like the TeeJet 4193A may fit inside the cap.

If your wand does not have this thread, you will have to find out what thread your wand is and use appropriate pipe fittings to add a nozzle thread body or adapter to accommodate a check valve. Another option would be to install an inline check valve like this ¼-inch polypropylene one from Specialty Mfg. Do note that this check valve has a 2 psi cracking pressure, so this won’t stop any drip until the pressure in your system is below 2 pounds. Depending on the pipe thread type on your wand, you may be able to find a check valve that will connect directly.