Sprayers are a significant part of turf care or property management business. It costs you money when your skid sprayers are in the shop for repair rather than on the job. Repairing sprayers take time, especially troubleshooting to determine the cause of your issue. One of the best ways you can reduce downtime is to properly winterize your skid sprayer at the end of the season.

Benefits of Winterizing Your Sprayer

Obviously, we know that there are benefits to winterizing your sprayers. However, or anyone who may be on the fence, here are some of the benefits that you may not have considered.

Extend the Life of Your Equipment

All the components on skid sprayers are going to wear out with use. Especially considering the corrosive attributes of the fertilizers, and other products used in turf and tree care. Taking the time to winterize will get the most out of these components.

Save Money

A new 200-gallon skid sprayer can cost $5000 or more. Every additional year you can get out of your sprayer is money saved. Winterizing can reduce rust, and corrosion, and keep the rubber components of the pump, controllers, and spray guns from chemical “attacks”

A new diaphragm pump for lawns and trees can cost $1000 or more. Repair kits, anti-freeze, and other products needed for winterizing your pump only cost about $200 per pump. You can save $800 a year if you maintain the pump and don’t need to replace the pump.

Less Downtime

Little needs to be said here, if your sprayer is breaking down you will accomplish less and spend more time doing service on your equipment.

Quicker Start In Spring

When the time comes for you to roll out your sprayer for the working season you won’t have to spend near as much time getting things running. If you took the time to winterize your sprayer then things will be much more likely to be in working order after the offseason.

Skid Sprayer Components

Before getting into the specifics of winterizing your unit, we should define the common components of skid sprayers so that we are on the same page. Skid units or “spray rigs” as they are sometimes called, consist of the frame, pump, tank, control units, hose, hose reel, strainers, and spray guns. These are the main components that just about all lawn or tree sprayers will have.

The specific pieces will vary from sprayer to sprayer but generally speaking, they function very similarly. Below is a simple plumbing diagram for a lawn/tree skid sprayer.

Pump Maintenance

The centerpiece of the sprayer is the pump. It is the most complex piece of equipment that makes up your sprayer and the moving parts can wear out, especially if not operated or maintained correctly.

The type of pump you have will affect the winterization procedure. Skids sprayers for turf care and pest control will commonly use diaphragm pumps. Other pump types like centrifugal pumps, roller pumps, piston pumps, and 12-volt diaphragm pumps can be used, but medium and high-pressure diaphragm pumps are the most common.

Regardless of which brand of diaphragm pump you have, the winterizing program does not vary much. AR, Hypro, Udor, John Blue, etc., these pumps all function the same with slight variations in design.

Inspect Check Valves

Diaphragm pumps contain a set of check valves for each piston. Inspect the check valves for debris and damage. If the check valves do not open and close smoothly, replace them.

Replace Diaphragms

The barrier between the fluid that you are pumping and the oil in your pump is the diaphragm. They are subject to the most potential wear and chemical damage. They should be replaced every 500 hours or at the end of the working season. For a full guide to replacing the diaphragms, you can check out this video.

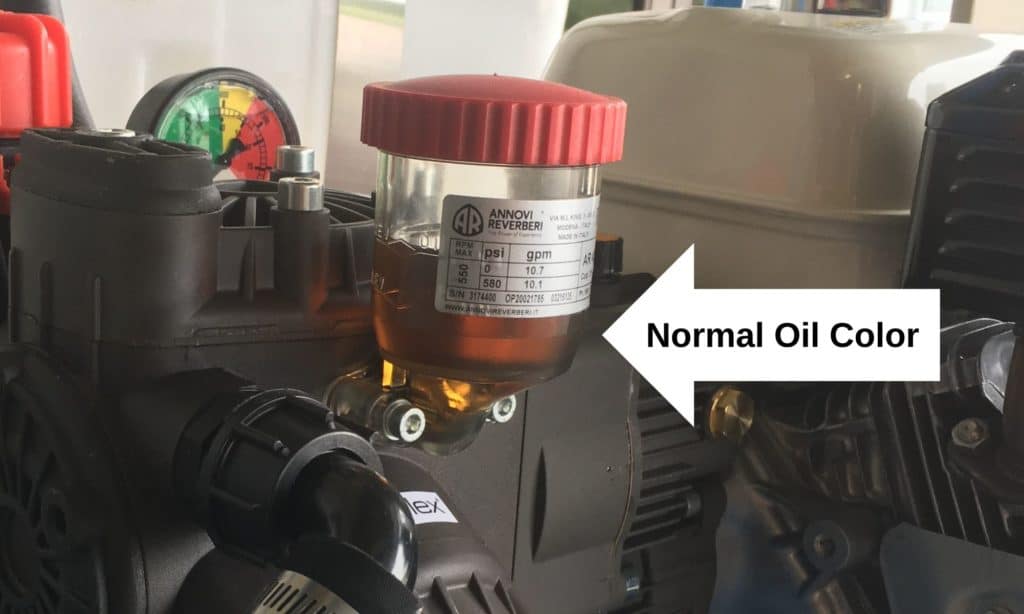

Change Crankcase oil

When diaphragms wear out they let chemicals or fertilizer get into the oil in the pump. Even if your oil looks fairly clean, it is a good idea to change the oil when you change the diaphragms. If the oil is milky or dirty looking then be sure to rinse out the crankcase thoroughly.

Clean The Pump

It is best to clean the pump off as often as possible, but removing the build-up of dirt, dust, and grime at the end of the season is essential to extend the life of the pump. Clean off any oil, fertilizer, or dirt to help prevent rust and corrosion.

Tip: If you do not keep a record of the model and type of pumps you are using, make sure to keep the nameplate or tag on the pump clean. This will help anyone to identify the pump when service or repair parts are needed.

Fuel

If you have a gas-engine driven pump, you will want to add a fuel stabilizer to the fuel tank. A quality fuel stabilizer will help your engine start in the spring. It also protects against rust, gum, and corrosion. This simple step will extend the life of almost any engine. STA-BIL is my preference for use in small gas engines when they will not be used in the off-season.

Flushing The Sprayer

You should flush your pump with fresh water at the end of each day. This will help to prevent chemical damage to the diaphragms. At end of each season, your entire system including the pump, tank, hose, etc, should be flushed with water.

Flushing Procedure:

Step 1: Pump out any remaining chemical mix or fertilizer from the sprayer tank.

Step 2: Add fresh water to the sprayer tank (enough to run the pump for a minute). With discharge valves and wands open, run the fresh water through the entire system: hose reel, agitation line, spray wand, etc.

Step 3: Ensure all water is drained from the system.

Cold Weather Protection

Ideally, you would want to store your sprayer pump in a climate-controlled building through the winter months. If this is not possible you will want to circulate antifreeze through the pump and system to avoid freezing. Circulate at low pressure only to avoid foaming.

Each diaphragm pump manufacturer has a slightly different recommendation for what type of antifreeze mixture to use and some even offer a special product to help preserve the pump.

Type of Anti-freeze to Use for Winterizing Your Pump

AR Pumps

Common Models: AR-30, AR-40, AR-50, AR403, AR503

Recommended Winterize Product: AR Pump Saver – Protects pump from freezing and keeps it lubricated.

Hypro

Common Models: 9910-D30, 9910-D50, 9910-D403, 9910-D503

Recommended Winterize Product: 50/50 mixture of RV antifreeze.

John Blue

Common Models: DP-43-FP, DP-70-FP, DP74.1, DP90.1, DP139

Recommended Winterize Product: Straight RV antifreeze

Udor

Common Models: KAPPA Series, DELTA Series, ZETA Series

Recommended Winterize Product: Antifreeze

Before Use Next Year

Before your next spraying season starts, there are a few things to check. Examine the oil level and coloring. Any milky coloring could mean worn diaphragms. You should also check your hoses and fittings for cracks. Replace filter screens if needed. Rinse all the antifreeze or pump-saver products from the sprayer with fresh water. Finally, operate the sprayer to test the pump and other components before you start spraying.

Preseason Maintenance Checklist for Diaphragm Pumps

- Check engine oil and pump oil.

- Check mounting bolts.

- Check hoses and fittings for cracks.

- Check strainer for debris or leaks.

- Purge all anti-freeze or pump-saver products from the sprayer.

- Inspect diaphragms for chemical damage.

With proper maintenance, a diaphragm pump can last for many years, just remember that the diaphragms are a wearable part that will need to be replaced regularly.

These straightforward steps will save you time in the long run and extend the life of your spray equipment.