One popular type of sprayer used for simple turf, pasture, and roadside spraying, is the roller pump sprayer. Roller pumps come in several sizes. They have a relatively simple design and they can be used with a small boom sprayer and with sprayer guns. They are great for people who need more flow and pressure than a 12-volt spot sprayer pump can provide but don’t want to spend the money for a high-pressure diaphragm pump.

Roller Pump Sprayer Components

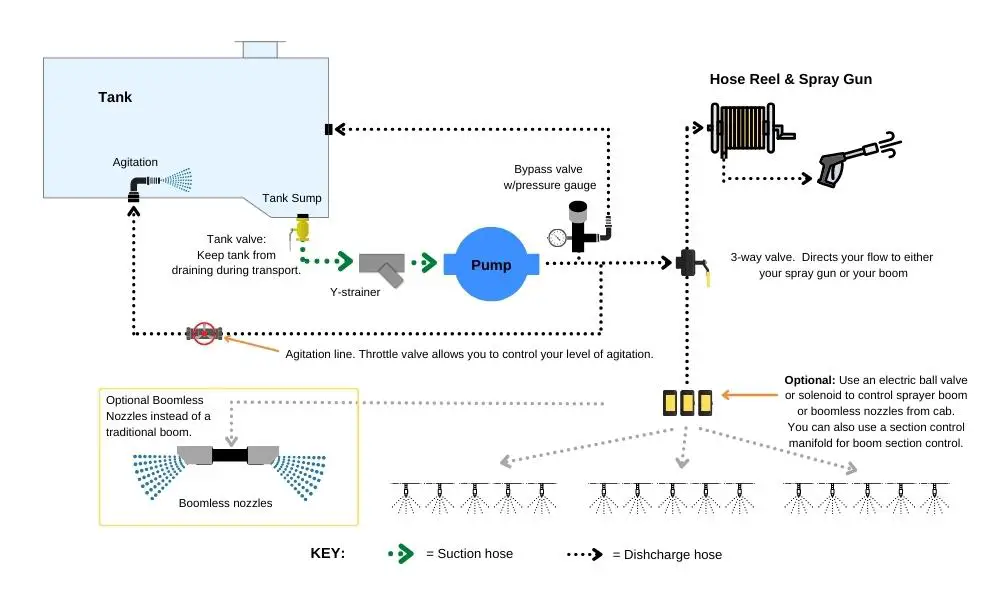

- Pump: There are many roller pump sizes available. They range from about 8 gallons per minute to 60 gallons per minute.

- Regulating/Bypass Valve: It is important to have a bypass/pressure relief valve on the discharge side of the pump. This will protect your sprayer. If you shut off your boom valves or spray gun with the pump still running, the pressure in the system needs to be bypassed back to the tank to avoid damage.

- Tank: Your sprayer tank should be sized to accommodate the flow of your application. If you spray at a rate of 10 GPM, you will empty a 100-gallon tank in only 10 minutes. Be sure that your tank is large enough that you do not have to constantly refill, but also keep in mind the total weight of a loaded tank. For more information on sprayer tank size, you can read this article.

- Agitation: A simple gate valve or throttle valve can be used to set the amount of liquid that is used for agitation in your sprayer.

- Spray Boom: Roller pump sprayers produce enough volume for a traditional spray boom or with a set of boomless sprayer nozzles.

- Spray gun

Pros of Using a Roller Pump Sprayer

Roller pumps are positive displacement sprayer pumps that provide higher flow rates than 12-volt pumps while producing higher operating pressures than centrifugal pumps. This makes them effective for small spray booms and boomless nozzles as well as high-volume spray guns.

Roller pumps have a simple design that can be rebuilt easily. They work well when PTO-driven or gas-engine-driven.

These pumps are commonly made with cast iron housings but there are roller pump versions made specifically to hold up to herbicides like Roundup.

Cons of Roller Pump Sprayers

Roller pumps do not produce the high volumes that centrifugal pumps can produce, limiting the size of the sprayer boom or nozzles you can use. They do produce more pressure but the larger roller pumps max out at 200 psi, this makes roller pumps capable of reaching spray distances of about 40-45 feet. If you want to spray tall trees you will likely need to opt for a diaphragm pump.

While roller pumps can be repaired, the pump housing can wear out to a point where they are no longer able to be made to perform effectively.

Roller Pump Plumbing: Critical Factors to Remember

When installing a roller pump, there are some important precautions to take to protect your pump and ensure that it will operate smoothly for as long as possible.

Use the Right Suction Hose Size

Be sure that the suction hose you use is at least the same size as the pump inlet. For example, a 1-inch roller pump should be fed by 1 inch inside diameter suction hose. If you run the roller pump with a 1000 RPM PTO, then you should oversize the suction hose. In our example, you would want to use a 1-1/4 inch inside diameter hose. To be safe you can always use a larger suction hose, this way you will not starve your pump.

You should also be sure that the suction hose is a reinforced hose that does not collapse when the pump is in use. Standard rubber spray hose will not work for suction, only for the discharge side.

Pressure Relief

Roller pumps are positive displacement pumps. This means that they need to have pressure relief on the discharge side to bypass your liquid if you shut off your boom or spray gun. This is shown and mentioned above, but it is important that this is installed correctly.

You can use any regulating valve that is rated for the pressures that your pump will produce. For most roller pumps, the maximum pressure is about 150 PSI but some do reach higher pressures. A brass or iron regulating valve will hold up to the vibration and higher PSI, while poly and nylon regulating valves won’t rust.

Conclusion

Roller pumps are a great choice for a low-cost sprayer pump that will give you more flow and higher pressure than 12-volt pumps. Just remember that they require some more specific plumbing and maintenance than 12-volt pumps.