A line strainer is a key part of basically any type of sprayer. Whether it is a lawn, turf, crop, or de-ice sprayer, it is important to use a strainer to remove any debris or particulate matter from the liquid being sprayed. Strainers can be installed in multiple locations on a sprayer. They will typically be installed in the suction line between the tank and the sprayer pump, but they can also be used prior to spray guns, or booms. They are designed to prevent clogging and damage to the spray equipment.

Line strainers come in various sizes. They vary in port size and the volume they can handle as well as the mesh size of the screen inside. The strainers used on sprayers are usually made of polypropylene and sometimes stainless steel because they are durable and resistant to corrosion and chemical damage.

The use of a line strainer in a lawn, turf, or agriculture sprayer is important because it helps to ensure that the liquid being sprayed is free of any debris that could clog nozzles or damage the sprayer pump, flowmeter, etc. Clogged nozzles prevent the sprayer from evenly applying the spray mixture. By removing these particles, line strainers can improve the performance and longevity of the spray equipment, as well as the quality and effectiveness of the sprayer.

Related: Complete Sprayer Components List

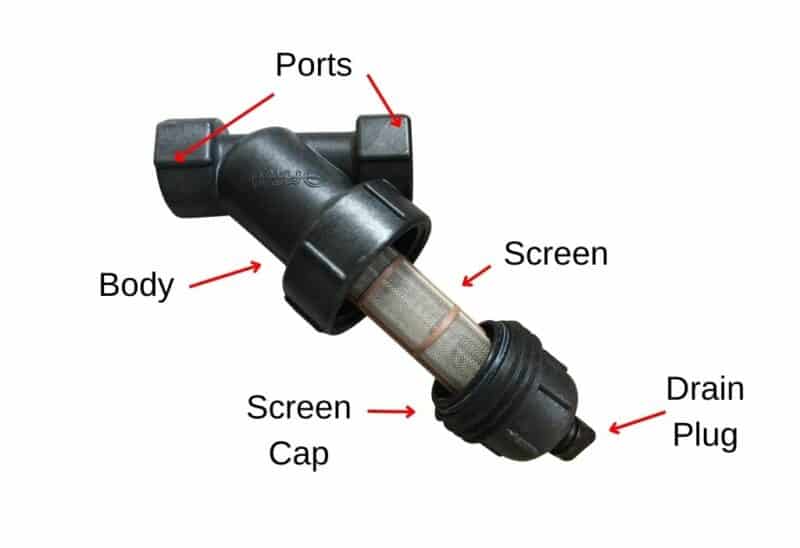

Parts of a Sprayer Strainer

A line strainer typically consists of several parts. These components work together to filter the liquid being sprayed. While there are several manufacturers and different strainer options available, the basic parts of a line strainer include:

- Housing: This is the main body of the strainer that contains the filter screen. The housing contains the inlet/outlet connection ports for the hoses or pipe. These ports are usually threaded.

- Filter Screen: This is the part of the strainer that actually filters out the debris. It fits inside the strainer housing and bowl. It is typically made of a stainless mesh. The size of the screen can vary depending on how small debris or particles you needed to filter.

- Gasket: The gasket (or o-ring in some strainers) creates a tight seal between the housing and the strainer bowl and keeps the strainer from leaking.

- Strainer Bowl: This is the part of the strainer that holds the filter screen in place and is either threaded or clamped to the main housing. It can be removed to access the screen for cleaning or replacement.

- Inlet and Outlet Ports: These are the openings in the housing through which the liquid flows into and out of the strainer.

- Drain Plug: This is a feature that may be included in some line strainers, which allows for easy draining of accumulated liquid or debris from the strainer.

Different Types of Strainers Used on Sprayers

There are quite a few different styles of strainer that can be used on a sprayer. Some are full assemblies that have multiple parts as shown above, but there are also simple strainers that are just screens. These can be used as suction strainers in small sprayers, or inserted in nozzle bodies to provide filtration for individual spray nozzles.

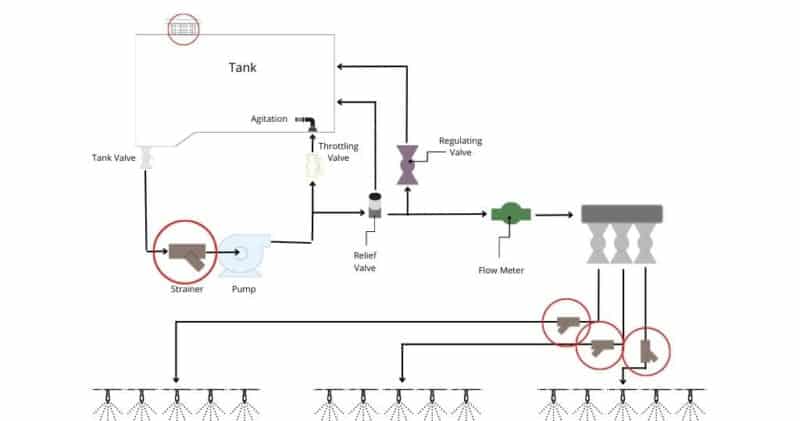

Suction Strainers: These are installed in the suction line between the tank and the sprayer pump.

Hose End Strainer: Strainer on the inlet of a suction hose.

Boom Strainers: These are installed at the start of each boom section. If you have a manifold that directs flow to each section, then a strainer can be placed at each manifold outlet.

Tank Strainers: A “basket” strainer in the tank opening allows the liquid in, but catches anything else that may fall in when the lid is open.

Different Strainer Sizes

Line Strainers come with different-sized mesh screens. The mesh size refers to the number of openings per linear inch in the screen, which determines the size of the particles that can pass through. There are several different mesh sizes available, including 8, 16, 30, 50, 80, 100 mesh, and more. The smaller the mesh size, the smaller the particles that can pass through the screen. For example, a 16-mesh screen will allow larger particles to pass through than an 80-mesh screen.

The choice of mesh size will depend on the type of liquid being sprayed and the level of filtration required. For thick liquids or liquids with higher levels of particulate matter, a larger mesh size may be needed to prevent clogging. If you are using a strainer to filter liquid going to a boom or spray gun, you may want a finer mesh to keep small nozzles from plugging.

Strainer Maintenance

Proper maintenance of your strainers will help to increase longevity and optimal performance. Over time, debris and other residues can accumulate in the strainer, which limits its effectiveness. Therefore, it is important to clean and flush the strainer regularly to ensure that it is free of residue, debris, or other foreign material.

To clean the strainer, remove the strainer bowl from the housing and empty any liquid or debris that has accumulated. Rinse the bowl and housing with water to remove any remaining debris. Next, remove the filter screen from the housing and inspect it for damage. If the screen is damaged or has a lot of debris accumulated on it, it should be replaced.

Choosing a Strainer for Your Sprayer

When choosing a line strainer for your sprayer, there are a few main factors to consider. Including the type of liquid being sprayed, the flow rate of your sprayer, and the level of filtration your application needs.

The type of liquid being sprayed will determine the type of strainer required. For example, if you are spraying chemicals or pesticides, you will need a strainer that is resistant to chemical corrosion. Polypropylene and nylon strainers are common for these applications.

As mentioned above, there are several sizes of screen available. For most turf and agricultural applications, 50 mesh screens will suffice. However, If you are using an especially small spray tip, 80 or even 100 mesh might be advisable to keep the tips from plugging.

The flow rate of the sprayer is another important consideration. A strainer that is too small for the flow rate of the sprayer may cause a pressure drop and affect the performance of the sprayer. A good rule of thumb is to make sure that the port size on your strainer is no smaller than the size of the line it is installed. For example, if you have a one-inch pump inlet, you will want to have at least a one-inch strainer. If you want a strainer to filter out fluid going to a boom, it should be the same size as the hose that supplies the boom.

Where Does the Stainer Go on a Sprayer?

Strainers can be used in multiple places on a sprayer. The main locations would be before the pump, before any boom sections, and before each nozzle. If your sprayer has a spray gun you can also use a stainer before the gun.

The goal of a strainer is to remove the particle that might plug or harm anything downstream from it. Using more than one sprayer may seem redundant but as your pump is worn down internal pieces can break and that debris will go through your sprayer. So even if you have a strainer before the pump, it is a good idea to use a strainer on the discharge side of the pump, especially if you have a flow meter, or other sensitive components.

Do I Really Need a Strainer on My Sprayer?

It is certainly possible to use a sprayer without a strainer, however doing so can lead to reduced performance, increased downtime, and potential damage to your sprayer components. It is strongly recommended that you use a line strainer on any type of sprayer, regardless of the size or type of application.