A sprayer is an important piece of equipment for farmers, ranchers, turf care professionals, and even homeowners. This essential tool has revolutionized the way we control weeds and pests, but have you ever wondered about the main components of a sprayer?

Sprayers are used to apply many different fluids on various types of crops, fields, lawns, etc. Using the same sprayer to apply herbicide on a lawn and then to spray tall trees, would not be possible. Sprayers are built for a specific type of application. For example, a lawn sprayer will use a different pump than a large crop sprayer, and a tree sprayer will use a different set of controls than an ATV sprayer.

Generally speaking, all sprayers will have these basic components:

- Pump

- Tank

- Plumbing

- Nozzle

- Controls

In this article, we’ll aim to break down the key parts of different sprayers and explain their function. We’ll cover everything you need to know about the aspects of several different types of sprayers including lawn and garden sprayers, ATV/UTV sprayers, boom sprayers, and more.

What is The Main Function of a Sprayer?

The main function of a sprayer is to apply liquids, typically pesticides, herbicides, and fertilizers, to crops, lawns, or other surfaces in an accurate and efficient manner. Sprayers vary greatly depending on the type of crop or field they are intended to cover, the size of the area they need to cover, and whether it is for residential, commercial, or ag use.

The Function of Each Sprayer Component

Depending on the type of sprayer these different components might be a single item or a series of items that together provide the capabilities necessary for the sprayer to operate as designed. Let’s dive into a bit more detail on each component and what they do, and some examples used for different sprayer types.

The Sprayer Pump

All sprayers must have some mechanism that propels liquid out of the nozzle(s). This might be a Simple assembly with a hand-operated lever that builds pressure or a large complex pump driven by a hydraulic motor.

The type of liquid application a certain sprayer is designed for will determine the pump type that is best suited for it. For example, diaphragm pumps are ideal for tree spraying because they can produce the pressure and flow rate needed to propel liquid to reach tall trees, while centrifugal pumps are more suitable for the high-volume needs of agriculture crop sprayers.

Different Types of Sprayer Pumps:

- Hand-pump

- 12-Volt Diaphragm Pumps

- Roller Pumps

- Diaphragm Pump

- Centrifugal Pumps

- Piston Pump

If you are interested in more specifics on each type of sprayer pump, then be sure to read this post about sprayer pumps where I cover each type in more detail.

Sprayer Tank

Obviously, sprayers need a container to hold the liquid that is to be applied. While the function of a sprayer tank might be straightforward, there is more to a sprayer tank than just the size. All sorts of different tank shapes and styles are used on sprayers. There are several factors that determine why a certain type of tank is used.

Capacity

The capacity of the tank is an important factor to consider. Bigger is not always better. Larger tanks are more expensive and heavier when full. They can also be hard to maneuver or install on smaller sprayers such as those used with UTVs or pickups. Settling on a tank size that is most suitable for your application will depend on a combination of how fast your sprayer will use up the liquid in the tank and how much weight your sprayer or vehicle can handle. You will want a tank large enough that you can avoid constant refills but light enough that you can safely pull/carry it on your equipment.

Material and Chemical Compatability

The material of the tank is also important. For example, polyethylene is most often used for fertilizer and herbicide sprayers. However, some sprayers that are made for use with petroleum-based products would not be compatible with polyethylene and would require steel or stainless steel tanks.

Tank Shape

Tank shape should not be overlooked. Some tanks are easier to clean and maintain than others. Tanks with larger lids provide easier access to the inside of a tank for cleaning. Tanks with sumps in the bottom drain out completely. If a tank has a flat bottom and no sump, liquid can stay trapped in the tank.

Overall, the type of tank used on a sprayer will depend on the specific application and sprayer type. The output of the sprayer, the size of your vehicle/equipment towing or carrying the sprayer, and the chemical being used will all factor into the type of tank used on a sprayer.

Sprayer Plumbing

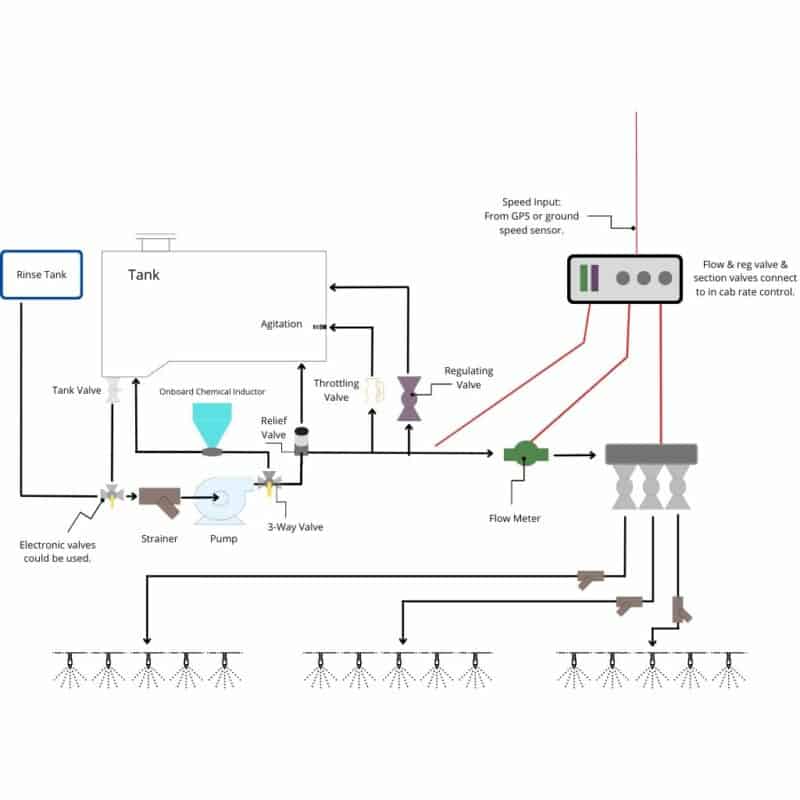

Plumbing is one aspect of a sprayer that is not just a single item but several items. It involves every aspect of how the fluid will travel from the tank to the spray tip. Plumbing can vary greatly from sprayer to sprayer. For example, backpack sprayers may have no more than a short hose and a couple of fittings while complex crop sprayers will have an elaborate system of meters, valves, pumps, tanks, filters, etc.

The way the plumbing is put together will have a major effect on the performance and features of a sprayer. Two separate machines might have the same pump, tank, and sprayer nozzles, but differences in plumbing can lead to them operating and performing very differently. This can also mean one may be more suited to a certain application than the other.

In its simplest form, a sprayer will have a hose that feeds the pump, then a hose on the discharge side (or pressure side) of the pump supplies fluid to the spray gun or boom. If the pump requires it you would have a regulating valve with a bypass line that sends liquid back to the tank to maintain pressure in the discharge hose.

Incorporating relatively inexpensive components (when compared to the pump, engine, etc.) in your setup will add features and increase the capabilities of your sprayer. For example, if you want the ability to agitate the liquid in your tank, you do not need another pump, you simply need to add an agitator jet or eduction nozzle in your tank wall and then run a hose from the discharge line to the agitator port in the tank. You can install a valve in the line to control when and how much flow is directed to agitate the tank.

You can see an example of a more complex setup below.

There are several features you can add to your sprayer with some simple plumbing changes:

- Manifolds/Section Control

- Agitation

- Rinse

- Metering

- Bypass/Pressure Relief

- Mix Tanks/Inductors

- Using the pump for loading/unloading the tank

For more information on plumbing sprayers, check out the several diagrams in this article on ag sprayer plumbing guides.

Nozzle(s)

A sprayer nozzle is a device that forms the appropriate-sized droplet and shapes the spray pattern. Different droplet sizes and spray patterns are necessary for specific spray applications. Without a nozzle, a sprayer is essentially just leaking liquid!

The nozzle determines several different aspects of your sprayers performance:

- Spray Pattern: The spray nozzle determines the shape and direction of the fluid sprayed. For example, one nozzle might produce a fan spray, while another a cone spray, and another a solid stream pattern.

- Droplet Size: One important aspect of sprayer nozzles is droplet size with smaller droplets providing better coverage and larger droplets generally reducing drift. There are nozzles made to produce droplets of all sizes.

- Spray Pressure: Nozzle size affects the pressure that can be achieved, particularly in backpack and hand sprayers.

- Spray Volume: The nozzle size also directly affects the output of the sprayer. A larger nozzle will apply more liquid per minute at the same PSI than a smaller nozzle.

- Spray Distance: This is relevant for spot sprayers, backpack sprayers, hand sprayers, tree sprayers, etc., and a sprayer that uses a spray gun and not a boom. The nozzle that develops a solid stream Will spray further than a cone or fan nozzle. The nozzle size needs to be matched up to the flow and pressure of the sprayer to achieve maximum distance. Related: How far will a pump sprayer reach?

There are different nozzles used for different applications:

| Sprayer Type | Nozzle Types Used |

| Boom Sprayers | Flat fan nozzles, stream nozzles |

| Boomless Sprayers | Boomless nozzles |

| Lawn & Turf | Flat fan nozzles, flood nozzles |

| Tree & Skid Sprayers | Long-range spray guns with orifice nozzles, “shower head nozzles” |

| Spot Sprayers | Adjustable nozzles, cone nozzles |

New to sprayers and nozzles? You can learn a lot more about the different nozzle types, and how to select the right one for your needs by reading these articles:

How Do I Choose a Nozzle for a Boom Sprayer?

Is There a Standard Sprayer Nozzle?

What Does the Color of a Sprayer Tip Mean?

Sprayer Controls

Whether you have a garden sprayer, ATV sprayer, or tree sprayer, you will need some way to control the sprayer. It may be as simple as a trigger handle on a spray wand or much more complex with mechanisms to adjust the sprayer output, pressure, and direct flow of two different sections on a boom as well as turn on and off accessories for agitation or rinse.

Lawn Sprayer Controls

Lawn sprayers are generally made with very simple controls. The sophisticated controls are not necessary because there is seldom a need to make adjustments as you spray. A typical lawn sprayer will have a regulating valve to control pressure and a few manual ball valves to direct flow to a boom or spray gun.

Spray Rig & Skid Sprayer Controls

Turf and tree spray rigs are usually stationary when in use and Application is done by hand. The operator can make adjustments to the pressure while spraying if necessary. This is similar to small lawn sprayers but the regulating valve and on/off valves used are designed to handle much higher pressure.

Boom Sprayer Controls

Boom sprayers range in complexity. Due to the size and the need to adjust the rate as speed changes, Even simple sprayers will often have electronic controls. These controls give the operator the ability to turn the boom on and off. It also allows the operator to control the pressure. This can be done manually or via an automatic rate controller.

When used in agriculture there Is a need for precision controls. Applying Herbicides and fertilizers accurately helps reduce growers’ input cost per acre. These sprayers are equipped with a set of components that ensure the correct amount of liquid is used.

The items necessary to accomplish this will include a flow meter, regulating valve, rate controller, multiple boom section valves, and a speed sensor. Sprayer controls can be confusing, but this guide on electronic spray controls keeps things simple and covers what you need to control your sprayer output.

What is the most important part of the sprayer?

The most important part of a sprayer can vary depending on the type of sprayer and its intended use. Generally speaking, the most important part of a sprayer is the nozzle.

This is true for broadcast/boom sprayers. The nozzle has the most influence over how your herbicide or chemical is dispersed and how it covers your intended target. many different types of chemical products need to be applied in a particular fashion and the nozzle is what determines this.

The nozzle/spray tip is also the most important part of spot sprayers and hand sprayers. Hand pump sprayers generally all produce about the same PSI, but if you change the nozzle you can completely change the spray pattern, droplet size, and spray distance of the sprayer.

The same is true on a spot sprayer. Even though there is more variation in pump size on these sprayers. Nothing will have as big of an effect on what your sprayer can do or be used for, like changing the nozzle type.

By selecting the appropriate nozzle, you can optimize the performance of your hand pump sprayer for your specific application. A nozzle with the right combination of spray pattern, droplet size, pressure, and distance can help ensure that the herbicide is applied effectively and efficiently.

If you are a beginner when it comes to sprayers or sprayer nozzles then this article answers several common spray nozzle questions.