If you have ever looked closely at your sprayer nozzles you probably noticed a set of letters and numbers stamped on them. If you are curious like me, then you probably wonder what those numbers mean. Fortunately for you, I have sat through numerous meetings and training seminars on this very topic and I can provide you with the answer!

The numbers on a spray nozzle typically provide critical information about the spray pattern and flow rate of the nozzle. The first part of the nozzle’s designated number refers to the spray angle. The next set of numbers typically represents the flow rate of the nozzle at a specific pressure (typically GPM at 40 PSI)

You may have more questions about the meaning of these numbers and how they affect your sprayer, so let’s break down the story behind the numbers on your sprayer nozzle.

Sprayer Nozzle Part Numbers: Full Explanation & Examples

There are so many different types of sprayer nozzles, that one numbering system does not cover them all. To learn more, you can check out all the different types of nozzles in this article. However, with flat fan spray nozzles, there is a standard numbering system used throughout different industries.

If your nozzles are on a spray boom, they are likely flat fan nozzles they will follow the standard numbering system regardless of the nozzle manufacturer. The numbers on a flat fan sprayer nozzle indicate the type of nozzle, the angle of the spray pattern, and the nozzle’s orifice size. Some nozzles will also have letters that indicate the material of construction.

In this image, the nozzle is marked with 8003VS. This would indicate a spray angle of eighty degrees and a flow rate of 0.3 GPM at the standard pressure (40 psi). The VS stands for Visiflo Stainless. This is a TeeJet product description that indicates a stainless steel tip or orifice.

Here’s a breakdown of what these numbers indicate:

- Spray Angle: The first part of the nozzle’s designation often refers to the spray angle. This is the angle at which the spray is emitted from the nozzle. Common spray angles are 80 degrees and 110 degrees, indicated by numbers like 80 or 110 in the nozzle code.

- Flow Rate: The next set of numbers typically represents the flow rate of the nozzle at a specific pressure. This is usually measured in gallons per minute (GPM) at 40 PSI. (More info on nozzle flow rate in this article on nozzle sizes)

- Nozzle Type: The letters often indicate the spray pattern type produced by the nozzle. For instance, XR (Extended Range), TT (Turbo TeeJet), and AI (Air Induction) are common designations in TeeJet’s nozzle line. Each of these letters corresponds to a different spray pattern and droplet characteristics.

- Brand: Often the brand of the spray nozzle is listed. For example: Hypro, TeeJet, Wilger.

- Material: Commonly, the material the nozzle is made out of is indicated by a letter(s) on the tip

Different Nozzle Materials:

- Stainless Steel (SS): Nozzles labeled with ‘SS’ are made of stainless steel. Stainless steel nozzles are known for their durability and resistance to corrosion, making them suitable for a wide range of chemical applications.

- Polymer or Plastic (VP, TP, or P): Letters like ‘VP’ (VisiFlo Polymer), ‘TP’ (TeeJet Polymer), or simply ‘P’ indicate that the nozzle is made from a polymer or plastic material. These nozzles are generally more cost-effective and resistant to certain chemicals. However, they may have less wear resistance compared to metal nozzles.

- Ceramic (C or XC): Ceramic nozzles, indicated by ‘C’ or ‘XC’, are extremely wear-resistant and are suitable for applications where abrasive chemicals are used. They tend to have a longer life compared to stainless steel and polymer nozzles.

- Brass (BR): ‘BR’ denotes brass construction. Brass nozzles are less resistant to wear and certain chemicals compared to stainless steel or ceramic nozzles but are commonly used for some applications due to their good balance between cost and durability.

Other types of nozzles like flood tips, adjustable nozzles, boomless nozzles, and tree-spraying nozzles, do not follow a universal numbering system but they will still have a number that indicates the nozzle type and size.

You can learn more in this article on choosing a sprayer nozzle.

Where to Find a Sprayer Nozzle Number

Sometimes the sprayer tip part numbers are listed on the nozzle, and sometimes they are harder to see. The numbers may be on the side of the nozzle or the very tip near the nozzle opening.

In the image below there is a sprayer nozzle with the part number: MR110-06. The two letters are the nozzle type, MR (red box in the image below). Then the first three numbers are the spray angle, 110 degrees (blue box in the image below). Followed by the last two numbers that refer to the orifice size of the nozzle, in this case: 06 (green box in image).

Sprayer Nozzle Types

Just like with other pieces of equipment, each spray nozzle manufacturer has their own product names for each type of nozzle they produce. There is no one-size-fits-all nozzle. There are differences in the spray pattern, droplet size, material of construction, and more. The letters at the front of the spray nozzle number will indicate the nozzle type.

In the image above you can see an “MR” spray tip made by Wilger. “MR” stands for mid-range reduction. This refers to the level of drift reduction that this nozzle type offers. The MR tip will produce a medium to very coarse droplet size, depending on the orifice size and pressure (more on this later). This style nozzle is a flat fan spray tip made to fit on a sprayer boom.

The difference between different flat fan sprayer nozzles is subtle. Different nozzle types may look a little different but the spray pattern and droplet size they produce is what separates them. You can see in the chart below some examples of flat fan sprayer nozzles. The differences are small but they are intended to meet specific spray needs.

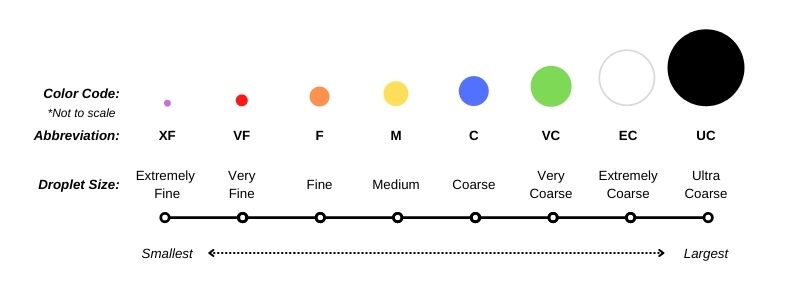

Spray Nozzle Droplet Size

Droplet size is important because it affects spray coverage and the drift a nozzle creates. A smaller droplet may provide better coverage but it is affected by wind and more likely to drift away from your intended target. Coarser droplets may not provide the same surface coverage, but they are prone to less drift.

Droplet sizes are measured in microns, the bigger the number the larger the droplet. Smaller droplets are called fine, very fine, and so on. Large droplets are referred to as coarse, very coarse, etc. Orifice size and pressure can affect droplet size. Nozzle manufacturers will have charts showing the droplet size for a nozzle at different pressures. Generally, as pressure goes up the droplet size becomes finer no matter what kind of spray nozzle it is.

Sprayer Nozzle Angle

Flat fan and cone nozzles come in different spray angles. This is what the first set of numbers on a sprayer nozzle indicates. The most common for ag or turf spraying is 80 and 110 degrees, however, many more angles are available.

Choosing the correct spray angle will be based on the nozzle spacing on your sprayer boom and the height of your boom during operation. 110-degree fans allow your boom to be closer to the ground while still overlapping each nozzle to get good coverage and reduce drift.

Sprayer Nozzle Size

The last set of numbers provides the orifice size. This is the size of the opening in the tip and it directly correlates with the flow rate at 40 psi. This way of numbering nozzle sizes comes from an ISO standard for sprayer nozzles. For an 06-size tip, the flow at 40 psi is 0.6 GPM. The chart below shows the different nozzle sizes that are universal for flat-fan and cone nozzles used on sprayers.

The spray nozzle color code is a universal way to identify the flow capacity of flat-fan sprayer nozzles. It helps you to easily identify what the flow rate of your nozzle is regardless of the manufacturer or nozzle type.

How do I know what Spray Nozzle Size I need?

Every nozzle type will have a chart that the manufacturer provides. The nozzle charts will show the different outputs for each spray nozzle at different PSI as well as the droplet size that is produced at that PSI.

The nozzle size you need will be based on your application rate. To determine the size of the nozzles for your sprayer boom, you will need to know these 4 things:

- The gallon per acre rate you want to apply (GPA)

- Your preferred operating pressure (PSI)

- The speed you will travel (MPH)

- The spacing between your nozzles (Inches)

You can figure your gallon per minute using this formula:

(Gallons Per Acre X Mph X Nozzle Spacing) / 5940 = GPM Per Nozzle

Once you know the GPM flow rate you need to achieve your desired rate, you can refer to the nozzle chart to identify what size tip you should use.

How to Read a Spray Nozzle Chart

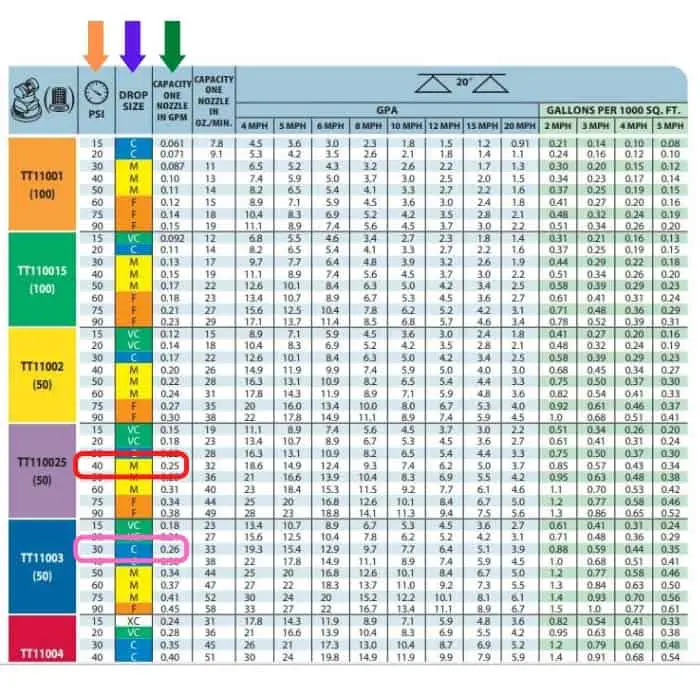

Below is a sprayer nozzle chart from TeeJet. It shows the capacity and droplet sizes produced at a certain pressure for the “Turbo TeeJet” nozzle type. You can see in the far left column the sprayer tip number. Notice the numbers are the same except for the last couple of digits. TT is the code for the nozzle type, 110 is the spray angle of the fan, and the last couple of digits refer to the nozzle’s capacity.

Let’s walk through an example of how to figure out your GPM and use the nozzle chart.

Example: An ATV sprayer boom with 3 nozzles spaced 20 inches apart. You desire to travel 5 MPH and the rate you need to apply is 15 GPA. So you would take 15 (rate) x 5 (speed) x 20 (spacing), then divide the total by 5940. Your total GPM needed per nozzle comes out to just over 0.25 GPM.

Now you need to refer to the nozzle rate chart to find a tip that puts out .25 GPM at the appropriate pressure you want to spray at. In the chart above you can see the GPM capacity if shown in the column marked with the green arrow. In that column, you would look for 0.25. In this scenario, you can see that the purple-colored tip, number TT110025, will produce 0.25 GPM at 40 PSI. The chart also shows that it will produce a medium-sized droplet.

This tip is not our only option though. The TT11003 (blue) tip would also work. While we don’t have 0.25 GPM exactly, we do see 0.26 at 30 PSI. So at roughly 28 PSI this tip would flow about 0.25 and create a coarse droplet size. If you wanted to operate at a lower PSI and have less worry about drift, the TT11003 would be the nozzle you want to choose.

Spray nozzle charts can be complicated, for a complete guide be sure to read this complete guide on understanding spray nozzle charts.

Non-Flat Fan Sprayer Numbers

When it comes to most other types of sprayer nozzles, spot sprayer nozzles, boomless nozzles, etc., there is no universal numbering system. However, the numbers will still provide us with some information about nozzle type and capacity.

Most nozzles have a number on them. This number usually correlates to the nozzle’s capacity. Just like with flat-fan nozzles, there will be a chart provided by the manufacturer, this will provide the flow rate/capacity info.

As with flat fan nozzles, some of the numbers can be hard to find. Usually, they will have a number that tells you the nozzle size located somewhere on the tip.

Boomless nozzles have a wide range of sizes and spray patterns, but since they are meant to be used on their own or as a pair, their nozzle charts don’t require you to do as much calculation to find your GPM. In this post, you can read more about selecting a boomless sprayer nozzle.

Why The Numbers On Your Spray Nozzle Matter

Sprayer nozzles are made to perform in a specific way. If you don’t have the right nozzle your entire sprayer can be rendered ineffective. Knowing what the numbers on your sprayer nozzle mean will help you identify the right nozzles for your spraying task.