The sprayer nozzle is often overlooked, but it is arguably the most important part of your sprayer. Whether you’re dealing with herbicides, fungicides, insecticides, or liquid fertilizers, the right nozzle can significantly impact the effectiveness of your application.

There are hundreds of different types and sizes of sprayer nozzles available, so how do you know which one to use? I have spent the past 10 years helping farmers and turf care professionals select spray nozzles for their needs. I have also used spray nozzles myself and have guided my father (he is a farmer) in this process. In other words, I can no doubt help you to answer this vital question.

Selecting the right sprayer nozzle requires taking a look at several different factors including where you will be spraying, the crop you are treating, the target pests, what liquids you will be spraying, how much drift you can tolerate, and more.

Let’s start by looking at the specific factors that will help you determine the proper nozzle for your needs.

Key Factors for Spray Nozzle Selection

When beginning the process of zeroing in on a spray tip that will be most effective, you need to consider several factors of your specific application and scenario.

The best plan is to start by answering some questions about your application. Here are the main factors to consider:

- What pest (insect, weed, disease, etc.) are you trying to eliminate/prevent?

- Where is the pest (foliage, soil, roots, etc.)?

- At what stage will you apply your pesticide to the crop: pre-emerge, post, reproductive stage, etc.

- Where are you going to spray: near other vulnerable crops, near residences?

- What kind of pesticide, herbicide, fungicide, etc. will you use? What is the mode of action?

- What kind of sprayer or method will be used to apply the pest control product?

Answering these questions will help to point you in the right direction. This list is not exhaustive. Depending on your application there may be other factors to consider, like weather, temperature, time of year, etc.

Spray nozzle companies spend a lot of money researching and designing their tips for specific applications. Selecting a spray nozzle without much thought can lead to poor overall results. This is why going through the proper thought process to select a sprayer nozzle is crucial.

It may be that there are a few different spray nozzles that will work for your application. The key is finding the nozzle or nozzles that will meet your needs the best.

How to Choose the Correct Sprayer Nozzle Type

The specifics of your scenario dictate the type of nozzle you need. You can choose a nozzle without much consideration but the results could be ineffective or potentially harmful. To avoid any mishaps or waste money respraying, here are the steps to take:

1. Refer to the Pesticide Label

The pesticide label stands as your primary guide to successful application. It details essential information such as application rates, the pests it targets, and the specific conditions for use. Moreover, it frequently offers insights on the required gallons per acre, the type of nozzle best suited for the task, and proper nozzle spacing. It’s crucial to adhere to the recommendations provided by the pesticide label.

Remember, the label is the law! The instructions provided are not suggestions or “best practices” they are required. Not following the label can result in penalties, fines, etc.

2. Consider What Are You Spraying

The product that you are going to spray is important because the label may provide specific instructions on how to spray and what nozzle to use. For specific chemicals and pesticides, the product label may even tell you a specific type of tip or manufacturer’s part number to use. Many products will provide more general suggestions like: “Use a flat fan tip that produces a fine droplet size, or use a cone nozzle that produces a coarse droplet”. Other products may provide little to know advice.

There are different nozzles for herbicides, fertilizers, fungicides, etc. Generally, for herbicides, you will utilize a flat fan sprayer nozzle, fertilizer is generally applied by stream nozzles or flood tips.

The material that the spray tip is made out of is another reason why the product you spray is important. Some materials may not be compatible with your product. Most sprayer tips for ag, turf, & lawn use are made from materials like ceramic, acetal, polypropylene, and stainless steel. These materials will work with most chemicals, pesticides, etc., but it is smart to check. One material type may last much longer than others with specific products.

3. Consider How Will You Spray

The mechanics of how you will spray go along with what you are spraying. Most herbicides for row crops will be applied via broadcast spraying. These are flat fan spray nozzles overlapping on your boom to provide even coverage. Fertilizers may be applied via solid or multiple stream nozzles or flood nozzles. Lawn and turf spraying may be done with flood tips as well when drift is a concern.

Nozzle spacing on your boom is also a factor in determining your spray nozzle. 110-degree flat fan nozzles are most common now on ag sprayer booms. They allow for the needed overlap on 15 and 20-inch spacing, to provide effective coverage. 30 or 40-inch nozzle spacings, usually for fertilizer or turf spray, will require flood nozzles or extra wide fans 120 degrees or more.

Operating pressure is also a factor. Most nozzles have an operating range of about 20-60 PSI, and some have a larger range, of 15-90 PSI. Make sure that your operating pressure is within the range of your sprayer nozzle.

4. Identify How Much Spray Drift Can You Handle

Spray drift is simply defined as the movement of sprayer particles/droplets through the air away from their intended target. You will always have some drift but too much will reduce the effectiveness of your sprayer and can be harmful to neighboring crops and plants.

Spray nozzles come in different types that produce droplets of different sizes. Spray nozzles that produce smaller/finer droplets usually provide more thorough surface coverage but they allow for more drift potential. Some nozzles are designed to produce a larger droplet that will provide less drift. These nozzles use air induction or other means of design to accomplish this.

Air-induction nozzles are required when using certain types of herbicides in agriculture. If you want to learn more, please view this article about the difference between air-induced nozzles and conventional nozzles.

Regardless of the type of sprayer nozzle, droplet size increases as pressure increases. Each type of spray nozzle will have a chart that displays the droplet size that will be created by that nozzle at different PSI. View this post to read more about droplet size and how it is categorized.

You should refer to the label of the products that you spray to find guidance on the type of droplet size you will need. You can also consult your chemical salesman or agronomist.

What Kind of Nozzles Are Used on a Boom Sprayer?

Flat fan nozzles are among the most common nozzle types for boom sprayers in agriculture. They produce a flat, tapered fan-shaped spray pattern.

Tapered flat fan nozzles create a spray pattern that is denser in the middle and becomes less dense towards the edges. suitable for a wide range of applications, including herbicides, fungicides, and insecticides.

They are designed to overlap with the adjacent nozzles on the spray boom to provide uniform coverage over a targeted area when spaced correctly.

This type of flat fire nozzle comes in several different variations. They differ in the spray angle and the droplet sizes they produce. There are also different sizes of each spray nozzle variety.

RELATED: Sprayer Nozzle Frequently Asked Questions

How Does a Spray Nozzle Affect Your Application?

A nozzle affects three main aspects of your sprayer’s output: spray pattern, application rate, and droplet size.

Spray Pattern

The spray pattern is the shape of the liquid as it leaves the spray nozzle. There are several different types of spray patterns but the primary rioting used on a bone sprayer is a flat fan nozzle. For more info, you can read this page with a list of several different types of spray patterns.

Selecting the correct spray pattern is crucial for achieving the desired spray coverage and minimizing overlap or gaps. For flat fan nozzles, the spray angle is indicated by the numbers labeled on the nozzle. This numbering system follows an international standard.

Common spray angles are 80 and 110 degrees for agricultural applications. It is common for these nozzles to be spaced 15 or 20 inches apart. Narrower spacing allows for greater overlap and will typically result in more even coverage. This is something that agronomists will suggest especially with tapered flat fan nozzles that are designed to produce coarser droplets.

Application Rate

The application rate refers to the volume of pesticide, herbicide, fertilizer, or other treatment solutions applied per unit area of land. This rate is crucial for ensuring the effectiveness of the treatment while minimizing waste, environmental impact, and cost. Application rates are typically expressed in gallons per acre (GPA)

Determining the correct nozzle size requires understanding your desired application rate, which can be calculated using formulas that consider factors like gallons per acre, operating pressure, travel speed, and nozzle spacing.

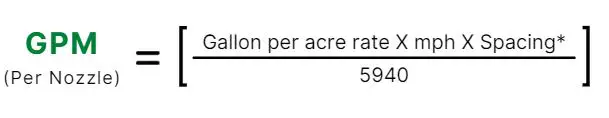

When you have pinpointed the gallon per acre rate you will need to apply, you then must calculate the size of the spray nozzle that will provide you that rate. This is the formula that is used to find the gallon per minute needed out of each spray nozzle:

To size your nozzle you need to know three things: your speed, nozzle spacing (inches), and your rate (gallons per acre). For a complete guide on how to use this formula and a handy calculator, read this article about sprayer formulas.

Once you have determined the gallon-per-minute flow rate you need from each nozzle, then you can use a spray nozzle chart to find the nozzle size that delivers that flow at your desired operating pressure. We will go over this more in a moment.

Droplet Size

Droplet size produced by sprayer tips is a critical aspect of the efficient and effective application of pesticides. The size of the droplets can significantly influence the coverage, drift potential, and overall efficacy of the application.

- Coverage: Smaller droplets can provide more uniform coverage on target surfaces, which is crucial for achieving effective control of pests or diseases. However, too small droplets might result in off-target movement or evaporation before reaching the target.

- Drift Potential: Larger droplets are less likely to drift away from the target area than smaller droplets. Managing drift is essential to prevent damage to non-target crops or areas and to comply with environmental regulations.

- Efficacy: The effectiveness of certain chemicals depends on the droplet size. For example, systemic herbicides might require finer droplets for better absorption, while contact herbicides might work better with coarser droplets that provide better coverage.

- Evaporation and Environmental Conditions: Smaller droplets are more susceptible to evaporation and wind drift. The environmental conditions, such as temperature, humidity, and wind speed, play a significant role in choosing the appropriate droplet size.

Droplet sizes are typically measured in microns (µm), where one micron equals one millionth of a meter. The categorization of droplet sizes is generally as follows:

| Category | Symbol | Color Code | Approx. VMD Range (microns) |

|---|---|---|---|

| Extremely Fine | XF | Purple | <60 |

| Very Fine | VF | Red | 60-145 |

| Fine | F | Orange | 145-225 |

| Medium | M | Yellow | 226-325 |

| Coarse | C | Blue | 326-400 |

| Very Coarse | VC | Green | 401-500 |

| Extremely Coarse | EC | White | 501-650 |

| Ultra Coarse | UC | Black | >650 |

To figure out how big the droplets are from a sprayer, experts use special tools and methods like lasers or fast cameras to look at the spray and figure out the range of droplet sizes it makes. They often talk about this in terms of “Volume Median Diameter” (VMD), which is like finding the middle size of all the droplets. This means that half of the spray is made up of droplets that are smaller than this middle size, and the other half consists of larger droplets.

Understanding Spray Tips and Nozzles

Knowing what you need from a spray nozzle in terms of size, pattern, droplets, etc. is half the battle. Identifying the spray nozzle that fits your needs requires an understanding of the numbering and nomenclature of spray nozzles.

Difference Between Spray Tips and Nozzles

The terms “spray tips” and “nozzles” are often used to refer to the same thing, but technically there is a difference. The nozzle is the entire unit that attaches to the boom or sprayer. It includes the spray tip, gasket, and nozzle cap/retainer.

The spray tip, on the other hand, is the part of the nozzle that actually forms the spray pattern. It’s the tip that determines the nature of the spray — its droplet size, pattern, and distribution.

Understanding this distinction can be quite helpful to ensure you are on the same page when discussing your needs with an agronomist, equipment salesman, or chemical rep.

Spray Tip Nomenclature

Spray tip nomenclature is a standardized system used to describe the characteristics of a spray tip, including its pattern, angle, and flow rate at a given pressure. The nomenclature typically includes a series of letters and numbers that provide specific information about the spray tip’s design, material of construction, and function.

For a complete breakdown of the numbering systems, read this article about what spray nozzle numbers mean.

Why Is Selecting the Right Sprayer Nozzle Important?

Selecting the correct sprayer nozzle is important for many reasons. The spray nozzle plays a huge role in determining the amount of chemical applied to a given area. It is also going to affect the coverage your sprayer can provide on the weed or surface you are spraying. Finally, the nozzle type will determine the droplet size which affects potential drift.

One example would be spraying a herbicide that needs to thoroughly cover the plant tissue. A fine droplet would be ideal. However, if the herbicide you want to use can only be applied with an extremely coarse droplet according to the label, what do you do? One option is to use an air-inducted dual fan nozzle.

This nozzle will spray extremely coarse size droplets but it produces two spray fans. This means you essentially hit the plant twice from a different angle with each pass. This meets the label requirements but also provides good coverage.

Boom Sprayer Nozzle Selection Guide

Let’s walk through a simple example of how to select a nozzle from start to finish.

Nozzle Selection Example:

Let’s say you want to spray a herbicide on corn. The label indicates that you should spray 15 ounces per acre of the product and 15 gallons per acre of the total spray solution. The label also says that you need to limit drift. It requires that the nozzle must produce extremely coarse droplets.

Your sprayer has a 50-foot boom with nozzle spaced every 15 inches. Your ground is mostly flat and you want to travel an average speed of 8 mph.

You can first use the 15-gallon per acre rate with your speed and nozzle spacing to determine the size of that is what you need. You can use the formula that was discussed earlier and you can find more information here. Take the rate (15 gallons per acre) times the nozzle spacing (15 inches) times the travel speed (8 mph).

This result is divided by 5940. The result is the gallon-per-minute flow rate needed at each spray nozzle. In this instance, we get 0.30 gallons per minute.

Then we look at a nozzle sizing chart. All flat fan spray nozzles follow the same international standard. The chart below is an example of what you would use. This can be found on any sprayer nozzle manufacturer’s website. For a more detailed explanation, refer to this guide to using spray nozzle charts.

The chart indicates that we can get a flow rate of 0.30 GPM from the violet, blue, and red nozzle sizes (025, 03, 04, nozzle sizes). However, these nozzle sizes will produce this rate at different pressures.

You want to identify the nozzle that will deliver your rate at your desired PSI. Typically you want the desired flow rate to fall near the middle of the operating range of the spary tip. This way you have room to speed up or slow down and maintain your rate. In our case, an 03 tip (blue) will spray 0.3 GPM at 40 psi. This is in the mid-range of the operating pressure. This range of pressure is that the nozzle will maintain a good pattern.

Now that you know the size, you need to find a nozzle that will provide the correct droplet size. This is where we have to refer to a spray nozzle manufacturer’s catalog of all the different spray nozzle types. For extremely coarse droplets you’re gonna want to look for an air-inducted nozzle.

If you look at a TeeJet catalog you’ll find that they have several options that provide extremely coarse droplets. For example, the TTI series of nozzles will offer extremely coarse (XC) droplets at 40-60 PSI. This is exactly what we need to follow the requirements on the label.

Where Can I Get Help Selecting a Nozzle for My Sprayer?

If you are new to spray nozzle selection, it can be a little overwhelming. Fortunately, there are many ways to get some guidance so you will be confident in your choice:

- You can call and talk to most companies selling spray tips. They can explain the differences and help you size your nozzle.

- You can also ask for advice from your chemical rep or agronomist about what spray tips can be most effective with the products you apply.

- Finally, you can always call the nozzle manufacturers directly:

Sometimes it just takes some trial and error. Only by testing different spray nozzle types will you find the ideal tip that will get you the best results in your scenario. This is a more costly endeavor but the cost of spray nozzles is not much compared to the cost of re-spraying, damaged crops, or yield loss.

You can always refer to the manufacturers but below is a chart I have put together different boom sprayer scenarios and what types of nozzles to use.

Different Sprayer Nozzle Types and When to Use Them

| Sprayer Application | Spray Tip Brand & Type* |

|---|---|

| Booms with 15-20″ spacing, small droplet/no drift concern. | TeeJet: XR, TurboTeeJet Wilger: ER, SR Greenleaf: TDXL |

| 15-20″ Spacing, Larger droplet for drift reduction. | TeeJet: AIXR, Turbo TeeJet Induction Wilger: DR, UR Greenleaf: TDXL-D |

| 30 or 40″ Spacing, Flood nozzles for fertilizer. | TeeJet: FloodJet, & Turbo FloodJet Hypro: HF Wide Angle Tip |

| 30 & 40″ Spacing on turf sprayer Flooding nozzles | TeeJet: Turbo FloodJet |

| Solid Stream Fertilizer Nozzles | TeeJet: StreamJet SJ3 and SJ7 Single Stream SS Nozzles |

Final Thoughts

It is crucial to have the right spray nozzle for the job. If you use the incorrect size nozzle, you can spray too much or too little. Which can be costly or render your spraying ineffective. The wrong nozzle type can lead to unwanted drift that may harm other people’s fields or lawns. Hopefully, this information will help select the right spray nozzle for your boom.