I have said it before, but the tiny sprayer tip is the most important part of any sprayer, whether it be a 2 nozzle turf sprayer or a self-propelled crop sprayer with a 120-foot boom. After all the point of spraying is to effectively cover our target surface with some liquid in the safest and most efficient manner. The sprayer nozzle has the greatest impact on this goal. More than the pump, the horsepower of the sprayer, the rate controller used, the size of the tank, etc.

Sprayer nozzle technology has advanced to a point where there are so many different variations of nozzles and several different products that require that you use a nozzle to achieve a certain spray pattern or droplet size. It can be overwhelming. So I put together a list of the most common spray nozzle questions and answered them.

Spray Nozzle Basics

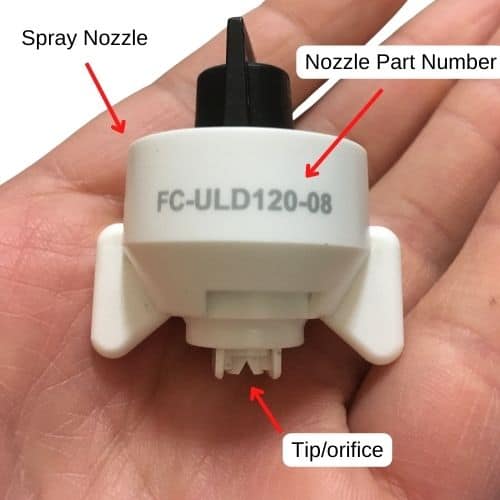

There are many nozzle designs and variations. When referring to different aspects of a nozzle it is important to be on the same page. Below are two spray nozzles. They are different sizes, different spray angles, and different manufacturers, but they still have the same basic aspects.

One main difference is the blue spray nozzle on the left is just the nozzle portion and the nozzle on the right is a one-piece nozzle with a cap and gasket included.

What Do Spray Nozzle Numbers Mean?

The numbers you find on a spray nozzle tell you the spray pattern and the capacity of the nozzle. In some cases, it can also tell you the type of nozzle, the manufacturer, and the material it is made from. The typical spray nozzle number will look something like this: 110-08.

The first set of numbers refers to the spray angle, in this case, it is a 110-degree fan. The second set of numbers refers to the nozzle capacity. This nozzle would have a 0.08 gallon per minute capacity at 40 psi (all capacities are rated by the nozzle’s flow rate at 40 psi.)

You can find a much more thorough explanation in this post about the standard sprayer nozzle numbering system.

What Does The Color of a Sprayer Tip Mean?

The color of a sprayer tip refers to its size. The size is the capacity in gallons per minute. The nozzle color code is the same for all flat fan nozzles. For a full sprayer tip color chart check out this post

What Is Nozzle Spray Pattern?

There are many, many different types of sprayer nozzles. The spray pattern of a nozzle refers to the shape and angle of the fluid produced by the spray nozzle. Every nozzle is designed to create the specific spray pattern needed to accomplish a certain task. Examples of different spray patterns include flat fan tapered nozzles, cone nozzles, and solid stream nozzles.

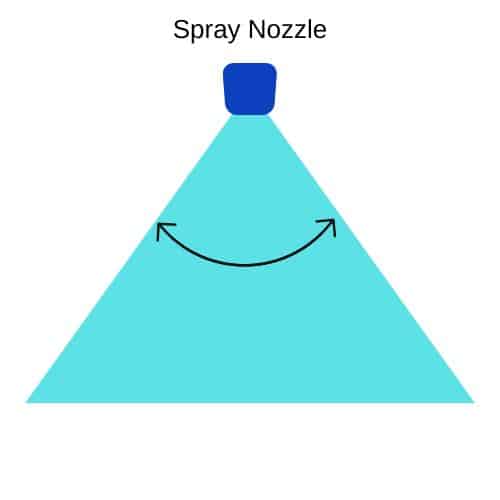

What Spray Nozzle Angle?

The spray angle is one aspect of the spray pattern produced by a sprayer nozzle. Spray angle is a measurement of the angle of the fluid as it leaves the tip. Whether you have a flat fan nozzle, cone nozzle, or a flooding type nozzle, the spray pattern angle can be measured.

What is the difference between 80-degree and 110-degree spray nozzles?

The numbers 80 and 110 refer to the angle of the spray pattern produced by a flat fan spray nozzle. The difference between an 80-degree and 110-degree nozzle is the width of the fan. An 80-degree flat fan nozzle will provide a narrower swath than a 110-degree fan.

What is a 15-degree nozzle used for?

15-degree nozzles are used for pressure washing. Specifically concrete surface cleaning, car wash, or paint removal. 15 degrees refers to the angle of the water as it is pushed out of the nozzle. Compared to other spray angles, a 15-degree angle is more focused. The more direct flow of water is ideal for moving mud, grime, paint chips, or other debris.

What is a 0-degree nozzle used for?

0-degree nozzles, also known as solid stream nozzles, are used for many different things. They can be used as jetting nozzles for unclogging drains. They work with high-pressure pumps to cut through different materials including plastics and metals. They are also effective for hydro-excavation. In agriculture, they are used to apply fertilizer precisely, and they are also used to apply de-ice/anti-ice solutions on roads.

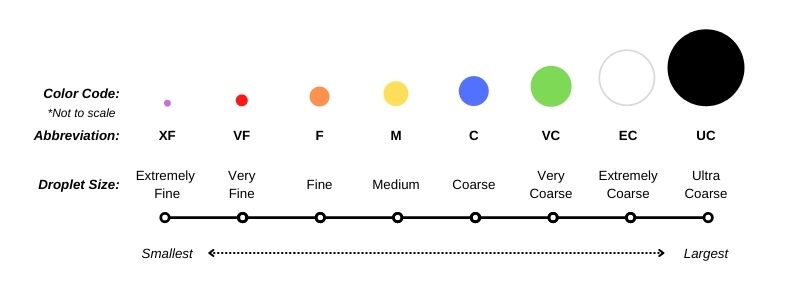

What Is Nozzle Droplet Size?

When a spray nozzle is in use it creates a pattern made of droplets. Different spray nozzles are designed to produce different sizes of droplets. Droplets are measured in microns. the different sizes are divided into different ranges of micron size and labeled. The smallest droplets are called extremely fine and the largest are ultra coarse. Here is the chart showing the droplet size range.

Why does droplet size matter? Some spray applications will get the best results with a small droplet while others may require a larger-sized droplet due to the weather conditions or environmental regulations.

If you are looking for a detailed guide to selecting a nozzle for a sprayer be sure to read my nozzle selection guide where I walk through all the aspects of selecting a spray nozzle.

How to Read A Spray Nozzle Chart

Selecting the correct nozzle type can be difficult, but identifying the correct size nozzle can be equally confusing if you are unfamiliar with sprayer nozzle charts.

Reading a nozzle chart correctly is crucial to ensure you choose a nozzle that will produce your desired application rate. The nozzle chart shows the flow capacity of each different nozzle size (also called orifice size) at a certain pressure. Flow capacity is measured in gallons per minute. That is the most important piece of information in a nozzle chart, but these charts typically contain a lot of other useful information.

When you know the flow rate you need from your nozzles, you can find what size nozzle produces that flow rate at an operating PSI that suits your nozzle type. For more information on how to calculate the flow rate you need from your sprayer nozzles, take a look at this post where I thoroughly cover how to find out what size nozzle you need.

You can read my full guide to sprayer nozzle charts here.

Spray Nozzle Formulas

How Far Apart Should Spray Nozzles Be Spaced?

The spacing of your sprayer nozzles is a fundamental aspect of chemical application. The spacing between your nozzles depends on your application.

- Spray Boom/Row Crop Sprayers: 15 or 20-inch spacing for flat fan 80 or 110-degree nozzles.

- Spray Boom – De-Ice/Anti-Ice: 8-10 inch spacing for solid stream nozzles.

- Boomless Nozzles: 3-4 inches apart for standard boomless nozzles.

How to Calculate Nozzle Size?

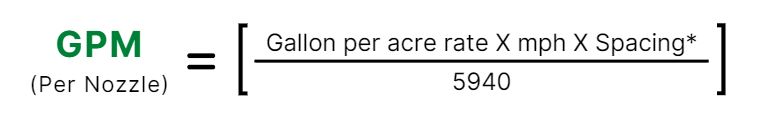

In order to calculate the size of the spray nozzle you need, you need to know your application rate. Then you must determine the gallons per minute needed per nozzle. The formula below shows you how to calculate this. Once you know the gallons per minute you can then find that flow rate in the spray nozzle chart and select the corresponding nozzle. If you are new to sprayer nozzle sizing be sure to view the full guide on sprayer nozzle sizes.

How to Calculate Gallons Per Minute

For boom sprayers, the formula is the rate (GPA) x speed x nozzle spacing (inches) divided by 5940. This will provide you with the gallon-per-minute flow needed from each individual nozzle.

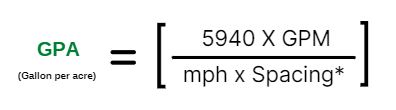

How to Calculate Gallons Per Acre

You can calculate your gallons per acre rate if you know these things: nozzle size, speed, nozzle spacing (inches), and operating pressure. Determine the flow rate of your nozzles (in gallons per minute) at your operating pressure. Then input this flow rate along with your speed and nozzle spacing into this formula:

Example: 5940 x 0.20 gallons per minute / 4 mph x 15 inches = 19.8 Gallons per acre output from your sprayer.

You can also find your gallon-per-acre rate by calibrating your sprayer. For more information, you can view this sprayer calibration guide.

How do I calculate the required spray pressure for my sprayer nozzles based on flow rate and nozzle type?

The operating pressure of your sprayer is one of the variables that directly affect the output of your sprayer. The operating pressure combined with the nozzle size will determine the gallons per minute flow rate of your sprayer.

In order to determine the operating pressure for your sprayer nozzles, you need to first determine how much fluid you need each nozzle to flow to achieve your application rate. There is a formula that is used to determine this amount:

Flow rate (GPM) = (Gallons per acre x Speed (MPH) x Nozzle width) / 5940

Once you calculate the flow rate you need for each tip (GPM), you can then refer the the spray nozzle chart. The chart will show you what PSI you need to operate the sprayer in order to produce the gallons per minute you need.

There are many factors at play when determining your spray nozzle, pressure, application rate, etc. For a full guide read “Sprayer Calibration Formulas: How to Calculate GPM & GPA”, It will further explain this concept and answer any other questions you may have.

How do I know the PSI of my Nozzle?

A spray nozzle does not have a specific pressure or psi at which it needs to operate. Nor is a spray nozzle designed to produce a certain psi. However, spray nozzles may need to be operated within a certain pressure range in order to produce a certain pattern.

Spray nozzles used For one, garden Garde, Pest control, agriculture, etc. will have a spray nozzle chart at displays their flow capacity at different pressures as well as the droplet size they produce at those different pressures. You can learn all about how to read and understand spray nozzle charts in this article.

Several factors play a role in determining the pressure that will be produced by a spray nozzle. The pump type, flow rate, plumbing design, hose size, temperature, and type of liquid will all affect the pressure.

Does a Smaller Nozzle Size Increase Pressure?

Yes, generally speaking, If all other things are consistent, a smaller nozzle size will result in higher pressure than a larger nozzle. In order to force the same amount of liquid through a smaller nozzle opening/orifice the pressure will need to increase.

There are several factors that can affect the pressure including pipe or hose size feeding the nozzle, pump type, flow rate velocity of the liquid, temperature, etc.

Different Spray Nozzle Types

What is a Flat Fan Nozzle?

Flat fan nozzles are spray tips that produce a pattern that resembles a fan when viewing it from the side. They are called “flat” fan nozzles because if you look at the pattern from directly below the tip, the width of the pattern is very narrow.

Flat fan nozzles are commonly used on ag sprayers, car washes, pressure washers, paint sprayers, pesticides, cleaning, and more.

In the image, you can see a tapered flat fan nozzle. This is a common type of flat fan nozzle used on boom sprayers. These nozzles are designed to overlap with the nozzles next to them to ensure uniform coverage.

What is a Cone Nozzle?

A cone nozzle is named for the cone-shaped spray pattern it produces. While from the side this type of spray nozzle may resemble a flat fan nozzle, when viewing the pattern from below the tip, you can see that the coverage area is round and not flat.

What is an Air Induction Spray Tip?

Some spray nozzles are designed to draw air into the droplets that are sprayed out of the tip. These nozzles are known as air induction nozzles.

An air induction nozzle is made for applications where larger droplets are required. Air induction tips typically produce coarse to ultra-coarse droplets.

If you have more questions about air-induced nozzles and when to use them, be sure to read this article about the difference between air-induced and standard nozzles.

If you are unfamiliar with the different types of spray nozzles available, you can find more information in this post on the different types of spray nozzles.

What is a Boomless Nozzle?

A Boomless nozzle is a spray nozzle that produces a wide coverage area with a single nozzle. They are called “boomless” because theoretically one or two of these nozzles can cover the same area as a boom. Boomless nozzles provide versatility and maneuverability that traditional boom sprayers don’t. If you are interested in learning more about boomless nozzles and boomless sprayers, check out this post on the best boomless sprayer nozzles, and this post on how to build a boomless sprayer.

Can I retrofit my existing sprayer with different nozzles, or do I need to consider other modifications as well?

In most cases, you can change the sprayer nozzles on your sprayer without making major modifications to your sprayer. It all depends on the type of nozzle body that is on your spray boom.

The nozzle body determines what types of spray nozzles will fit. There are quick-connect, quarter-turn nozzle bodies and there are threaded nozzle bodies. The difference is in the cap used to hold the spray tip on the nozzle body. Often spray nozzles will fit in either type of cap, but in some cases, they do not, although with adapters you can make just about any type of sprayer tip work.

There are many variations of nozzle bodies and different brands of spray nozzles that use different nozzles. For more specifics, see this full guide on how different nozzles connect and how to adapt them.