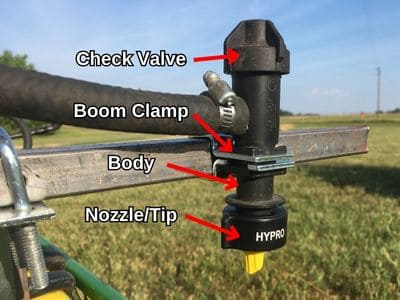

One aspect of a sprayer that is often overlooked is the nozzle bodies. Nozzle bodies are the component on a sprayer that connects the spray nozzle to the boom. They both hold and position spray nozzles. If you want to know how to fit a sprayer nozzle your sprayer then you need to know what type of nozzle body your sprayer has.

There are many different variations of nozzle bodies in use and they all have different features. The most noticeable way they differ is in the type of connection used to hold the nozzle in place. In this article we are going to cover the different types of nozzle bodies, how to fit nozzles on them, and why they are different.

Different Types of Sprayer Nozzle Bodies

Nozzle bodies range from very basic to extremely complex with multiple outlets, electronic solenoids, filters, and check valves. Fortunately, most are not this elaborate, and they are easy to identify and understand when you know the basics.

There are a few main ways that nozzle bodies differ: how they connect to the boom, how a nozzle connects to them, the material they are made out of, and finally any special features or extra components they may have such as check valves, or turrets.

A basic nozzle body is essentially a hose barb fitting. One end will contain thread that a cap fits onto, and the other end will be barbed so that a hose can fit over it. The cap holds the nozzle in place while the hose supplies liquid from the sprayer pump.

This type of simple nozzle body will work in any number of scenarios, but modern sprayers are equipped with more sophisticated nozzle bodies to offer additional features to the user. These features can benefit the user by making it easier and quicker to change nozzles, filter the fluid, eliminate dripping, and even provide the ability to shut off each individual nozzle on the boom.

Here are the different types of nozzle bodies, do note that a nozzle boy may fit into more than one of these categories if it has one or more of these characteristics:

Dry Boom Nozzle Bodies

There are two main types of sprayer booms: dry booms and wet booms. In this other article, I explain the difference in detail, but essentially one uses hoses to connect to each nozzle body (dry boom) and on the other, the nozzle body clamps directly onto a boom pipe (wet boom) that carries the liquid to each nozzle body.

The simple nozzle body described above is a “dry” boom nozzle body, however, they can come in many forms, the consistent factor is that a hose connects to each body. They might use threaded caps or quick-connect caps to hold onto the nozzle. They may even have a check valve to keep them from dripping, but the hose barb connection is what makes them a dry boom nozzle body.

They are held onto the boom itself via a clamp of some sort. Many of these nozzle bodies will have a collar or a channel on them made for a specific type of clamp. They can be mounted to round or square booms.

Wet Boom Nozzle Bodies

A “wet” boom does not have hoses supplying liquid to each nozzle, instead a hollow pipe runs the length of the boom. The nozzle bodies clamp directly onto the pipe. Small holes evenly spaced on the boom pipe feed liquid into each nozzle body.

Like a dry boom nozzle body, these can come in different varieties with many other features but they all connect to the boom this same way.

Threaded Nozzle Bodies

The original method for attaching nozzles to a sprayer was to use a threaded cap that would hold the nozzle in place on the nozzle body. The thread type used for this is universal, and it is known as nozzle body thread or Teejet thread. It is officially an 11/16th thread that is unique to sprayer nozzle bodies.

The caps used to “thread” onto the bodies are designed to hold any TeeJet-type sprayer tip. They will also hold in place just about any sprayer tip from most manufacturers.

Quick-Connect Nozzle Bodies

The ability to change out nozzles quickly has become important with the huge variety of different nozzles now used for many different applications. To make swapping nozzles easier, instead of thread, quick connect caps are used to attach to the body.

Spray nozzle manufacturers like Teejet and Hypro make nozzle bodies that accept the same type of cap or tip/cap combo. Other manufacturers use their own style of quick connect cap. Adapters are available to make tips from different manufacturers fit onto different bodies, more on this later.

Check-Valve Nozzle Bodies

Liquid dripping from the nozzles when the sprayer is not in use is less than ideal. To stop this from occurring manufacturers incorporated check valves into their designs. These valves only open when a certain pressure is reached. When the pump or boom section on the sprayer is shut off, the pressure drops and the check valve will close. This stops dripping.

Turret/Multiple Outlet Nozzle Bodies

For large-scale agricultural applications, an operator might need to change nozzles quite often. Turret-style nozzle bodies have multiple outlets to attach different nozzles. The “turret” can simply be turned when needed and the next nozzle snaps into place.

Adapting Spray Nozzles to Different Nozzle Bodies

The primary function of a nozzle body is to hold and I am the spray nozzle. But not all spray tips will fit on every type of nozzle body, at least not without the proper adapter.

As discussed earlier, there are two basic ways nozzles attach to nozzle bodies: threaded caps or quick-connect caps. There are also two types of spray nozzles: tip only or nozzle assemblies that consist of the tip, cap, and gasket.

Almost all sprayer tips on their own will fit into either style of nozzle body cap, threaded, or quick-connect. The nozzle assemblies will typically just be made to connect to a specific brand or quick-attach nozzle body, such as TeeJet, Wilger, Hardi, etc.

Whether the nozzle body is threaded or a “quick” connect style, the method for holding the nozzle in place consists of a cap, the nozzle, and a gasket. Often a strainer will fit just inside the nozzle body as well, but it is not required and may not fit with all nozzles or nozzle bodies.

If you have a spray tip held onto a nozzle body with a threaded cap, that same tip could be put into a quick-connect cap and be used on the quick-connect nozzle bodies as well. The nozzle assemblies that consist of the complete tip/cap/gasket can be put into other caps as well, assuming they are not a molded one-piece assembly. Some nozzles are solid pieces where the cap and tip are one piece, and in some cases, they can be separated and used with other caps.

The video below demonstrates how the different nozzle bodies and caps fit together:

TeeJet/Spraying Systems Company was the original creator of a lot of the “standard” nozzle bodies and spray nozzle caps that are used today. Many other manufacturers use the same nozzle body thread, and some even make quick-connect nozzle bodies that accept TeeJet spray tips and caps. TeeJet quick-connect nozzle bodies are called QuickJet nozzle bodies.

Here is a list of prominent spray nozzle types and if their quick connect caps and nozzles are compatible with TeeJet QuickJet nozzle bodies:

| Spray Tip Manufacturer | QuickJet (TeeJet) Compatible? | Adapter Needed |

|---|---|---|

| TeeJet | Yes | None |

| Hypro | Yes | None |

| Wilger | No | Wilger Part #40203-00 |

| Greenleaf | Yes | None |

| Hardi | No | TeeJet Part # 55240-CELR |

Non-Standard Nozzles

There are some exceptions to the general rules for connecting nozzles to a boom. Boomless nozzles and some other larger nozzle types generally do not fit the standard sprayer nozzle cap size, threaded, or quick-connect.

These nozzles will either have a specific cap or be made with some size national pipe thread. Often ¼ inch, ½, or ¾ npt. There are some larger flood nozzles often used on fertilizer applicators nozzles that fit into a ¾ inch female cam-lever coupling.

Conclusion

The ability to change your nozzles is essential if you want to be able to use your sprayer for many different applications. You can easily change nozzles and convert about any type of spray tip if you understand how nozzle bodies are designed and all their variations.