When it comes to crop sprayers there are many different variations. One major variation is the type of boom that a sprayer is equipped with. There are two main types: wet booms and dry booms. All booms carry liquid, so these terms might be a little confusing.

The difference between a Wet and Dry spray boom is how the liquid is carried on the boom and ultimately supplied to each spray nozzle. On a wet sprayer boom, the liquid travels through a rigid pipe and each nozzle body is attached directly to the boom. So the boom is “wet”. A dry spray boom uses hoses to supply liquid to each nozzle body and the nozzle bodies clamp onto a boom pipe or tube that does not have liquid flowing through it, so it is “dry”.

There are some key features of each type of spray boom. Let’s take a look at the different aspects of each type and their advantages and disadvantages.

Examples of a “Wet” and “Dry” Sprayer Boom

Wet Boom

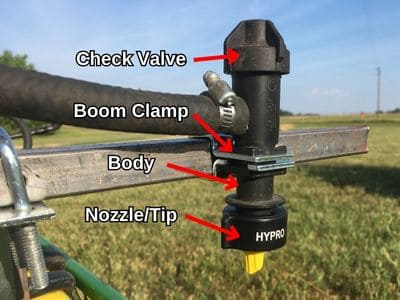

A “Wet” boom is defined as a boom that is made of a rigid pipe with nozzle bodies attached directly to it. The pipe carries the product to the nozzle bodies. The image below shows a wet boom.

Dry Boom

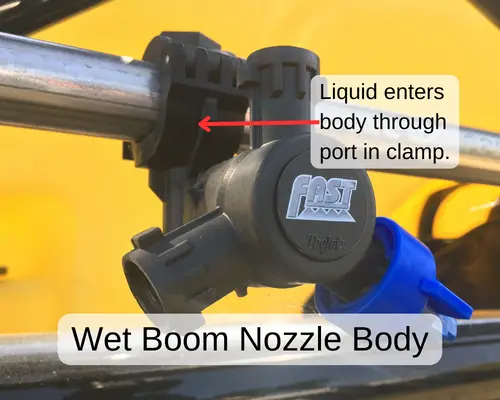

A “Dry” boom has nozzle bodies mounted to the boom frame with clamps and the product is supplied to the nozzle bodies via hoses. The image below shows a dry boom nozzle body.

Comparing Wet & Dry Boom Components

As you can imagine, whether you have a wet boom or dry boom, certain specific components are used with each one. For example, all booms need some type of nozzle body for the user to attach the sprayer nozzle. The nozzle is after all the main point of the spray boom. Let’s examine the specific components and how they differ.

Nozzle Bodies

The nozzle body is the part of a sprayer boom that the nozzle connects to. It will be held in place via a clamp and supplied by either the boom hoses (dry boom) or the wet boom pipe. There are many types of nozzle bodies. The simplest kind is basically just a hose barb elbow or tee with 11/16 nozzle body thread, commonly referred to as TeeJet thread. More complicated nozzle bodies have check valves to stop the nozzle from dripping, or multiple nozzle turrets to allow for quickly changing between different nozzle types.

There are many different types of nozzle bodies. For more information, this article explains nozzle bodies in much more detail.

Dry Boom Nozzle Bodies

A dry sprayer boom utilizes nozzle bodies that have hose barbs so that you can connect the boom hoses. These bodies are clamped onto the boom.

Wet Boom Nozzle Bodies

A wet boom nozzle body clamps around the boom pipe. The liquid enters the nozzle body from a hole in the clamp instead of a hose barb.

Boom Hose

A dry boom will have a rubber hose running the length of the boom to supply fluid to each nozzle body. EPDM rubber is the most common type but braided nylon hose can be used. EPDM has good resistance against agrochemicals.

A wet boom will not need any hose running from nozzle body to nozzle body, but there will be a hose that supplies each section of the boom pipe.

What Are the Advantages and Disadvantages of a Wet or Dry Sprayer Boom?

Wet Boom Advantages

- Easier to replace broken nozzle bodies. Just undo the clamp on the nozzle body and it comes right off.

- Easier to clean/flush out than dry booms.

- Small wet booms can be self-supporting, and therefore much simpler than a dry boom. You can see the example below is intended for adding to a small spot sprayer. It is much simpler than mounting nozzle bodies and running hoses to each one.

Wet Boom Disadvantages

- Can be more expensive than dry booms.

- If the boom pipe is PVC or poly it can break if it is hit by a fence, tree, etc.

- Must drill holes in the boom if you want to change the spacing of the nozzles.

Dry Boom Advantages

- No drilling or tapping pipe if you want to make changes to the nozzle spacing.

Dry Boom Disadvantages

- Hard to change nozzle bodies because you need to pull brittle old hoses off of the hose barb nozzle bodies.

- Boom hose cracks, sags, and wears out over time.

- Sagging hose between nozzle bodies can trap residue and make the boom harder to flush out.

Wet Vs. Dry Boom, Which is Best for You?

Ultimately the type of spraying and your personal preference will decide what works best in your scenario. Wet and Dry booms can be used for just about any size or type of sprayer. Ranging from small ATV booms to large row crop sprayers.

On smaller sprayers, a wet boom is a much simpler apparatus. However, if you damage a wet boom, you risk leaking fluid. A dry boom carries no fluid so if you hit something with your boom there is less of a chance of a leak. The hoses on a dry boom are more flexible and less likely to break in this manner.