When it comes to turf care and agriculture water is extremely important. Sometimes access to water is limited. When you need to get large amounts of water to supply a sprayer or water trees in a remote field, the solution is a water truck.

A water truck is made up of the same basic components as a sprayer. The difference is that the goal of a water truck is to move water at a high volume from place to place instead of trying to precisely apply liquid to a certain area. Building a water truck is straightforward but there are several things to be aware of to ensure your truck has the capabilities you need. Many things will affect the performance of your water truck like the horsepower requirements of the transfer pump, the friction loss from your plumbing, and even the color of the tank. Let’s dive into the details.

Water Truck Components

“Water truck” is a broad term that can refer to a variety of different types of trucks that can be plumbed in several different ways. There are some basic components that you will need to put together a water truck and there are several options for each type of component.

- Tank

- Pump

- Hose Reel

- Hose

- Nozzles

- Plumbing Fittings

Water Tank

The tank is the most prominent feature of a water truck or trailer. It will likely be the most expensive piece of your setup outside of the truck itself. Not all tanks are the same, especially when it comes to plastic/poly tanks.

Tank Material

Poly tanks are lightweight and relatively inexpensive. They do not rust and are made in many different shapes. Poly tanks can crack and in some cases are not as strong as steel or stainless steel. Because they are partially transparent they allow sunlight in and algae can grow in the tank. Many poly tanks manufactured today have UV inhibitors built in to reduce this problem.

The thickness of the tank wall does not necessarily mean it is a stronger tank. There are several factors to consider, like the type of poly resin used for the tank, the tank design, and the manufacturing process. To determine the strength of a tank you should consult the tank manufacturer to find out the specific gravity or SG that a tank can hold. Steel tanks are stronger than poly tanks, but they do rust and they can be more expensive than poly tanks. They are also heavier when empty than poly tanks. Stainless steel tanks are less likely to rust. They are very strong but they are also heavy and they are harder to repair than steel tanks. Stainless steel tanks are relatively expensive compared to steel and poly.

Tank Shape

Rectangular tanks or a tank with “feet” do not drain as easily as round or sphere tanks. However, a round tank may have a higher center of gravity than a rectangular tank, which is not ideal for mobile applications. Elliptical tanks provide the best of both worlds. They are rounded to provide easy draining, and they are shorter and wider, so the center of gravity is lower than round horizontal tanks. There are versions that are made with a slope to a sump in the bottom. This type will drain the best and will be easier to clean.

Whatever the shape of the tank, it is good to have a baffle in the tank. Water in a tank can move violently and create a risk of rollover or accidents. A baffle is a safety feature inside the tank. This reduces the movement of the water when stopping, starting, turning, etc.

Tank Recommendations

Elliptical tanks for water trucks:

Water Truck Pump Options

The main purpose of a water truck is to move large volumes of water when needed. For high-volume transfer, a centrifugal pump is the best option. There are two main types of centrifugal pumps, straight and self-priming.

A straight centrifugal pump requires that the inlet is flooded. In other words, the water level In the tank must Be above the inlet port of the pump. A self-priming pump is capable of drawing liquid into the suction port. Therefore a self-priming pump does not need to be installed in a spot where the water level will be above its inlet.

A self-priming pump is sometimes referred to as a trash pump. The trash pump first really pump that can handle some solids in the fluid is made to be more durable against debris it may be in the liquid. In many instances, you might be needing to fill the water trough from a lake or lagoon and you want a pump that can handle water that may have debris in it.

In many cases, you will want to be able to use your pump to unload and load the tank. A self-priming pump will provide you with the ability to move water fast. It will also pull water from an external source to fill your tank when necessary. For these reasons, a self-priming pump will be the better option in most scenarios.

Sizing a Pump for a Water Truck

The size of the pump you will need will be based on your individual needs. If you are planning to have a tank no larger than 500 gallons then a 3-inch pump capable of moving 350 gallons per minute is probably overkill. But, if you require a larger tank, say 3000 gallons, then the ability to unload and load it in roughly 10 minutes may be well worth it. A centrifugal pump can always be throttled down. Partially closing a valve on the discharge side to reduce the flow rate will not harm the pump. This means a pump that moves 300 gallons per minute, can be throttled down to 50 gallons per minute if a lower flow is needed.

This is also true if you will not only be using your water trying to transfer water but also want to use it for dust control. You do not need a separate pump to supply your nozzles used for dust control. The same pump can be used even if the nozzles are putting out 100 gallons per minute and the pump is capable of putting out 300 gallons or more per minute.

Pump Drive Type

A centrifugal pump can be driven by any source providing the necessary horsepower and rpm. On a water truck, your drive options are typically limited to gas or diesel engines, PTO, or hydraulic. The right pump to fit your PTO or hydraulic system will depend on your setup. You should seek out help from a pump distributor or truck service center/shop to make sure you find a pump that will work for you.

Using a gas-engine pump is a bit less complicated. The pump and engines are usually sold together so you do not have to guess or calculate how much horsepower or what RPM to run the pump at to achieve your desired flow. 2 and 3-inch engine-driven pumps are very common.

A 2-inch pump on a five-horsepower Honda engine is extremely affordable and will work great. They can move water at about 150 gallons per minute. 3-inch engine drive pumps require more horsepower and are a bit more costly, but you can usually achieve close to 300 gallons per minute. Do keep in mind that flow rates will vary depending on the plumbing and discharge head of any given setup. We will discuss this more shortly.

Hose

While the hose on a water truck may seem inconsequential, the wrong hose can actually cause major issues. The first key to remember is that the hose used from the tank to the suction/inlet of the pump needs to be a suction hose. A suction hose is reinforced and will not collapse due to the suction of the pump. Second, the suction hose, and all the plumbing pieces from the tank to the pump need to be no smaller than the inlet of the pump.

The pump can cavitate and leak from seal failure if these two conditions are not met. If you are new to centrifugal pumps be sure the read my article on troubleshooting a Transfer Pump.

The discharge hose does not need to be a suction hose, although it does not hurt to use a suction hose as a discharge hose. It is generally stronger and less likely to kink than non-suction hoses like rubber hoses or lay flat hoses.

Nozzles

Not every water truck will require nozzles. They are only necessary when you want to use the water truck for dust control. If you solely need to transfer water then you can skip this portion.

When a water truck is used for dust abatement then you will need nozzles that are high flow and cover a wider area that a normal flat fan sprayer nozzle. Boomless nozzles come in many sizes, and there are very high GPM options designed for dust control.

Plumbing

If you use a straight centrifugal pump on a water truck it would be best to be able to install it below the outlet port on the tank. This means it would likely need to be below the deck or bed of the truck and beneath the tank. This way the pump will always be flooded.

If you use a self-priming pump you have greater flexibility in terms of where you can mount the pump. You should install the pump as close to the tank outlet as possible. This decreases any risk of the pump running dry and will help it be more efficient. Having said this, the pump can essentially be installed anywhere on the truck, you could even theoretically put the pump on top of the tank and lift water out of the top. The simplest option is to mount the pump flat on the bed of the truck where it will be easy to access from the ground.

As I mentioned before, the entire fluid path from the tank outlet to the pump inlet needs to be at least the size of the pump inlet. For example, if you have a pump with a two-inch inlet, all the valves, strainers, hoses, etc., supplying the pump inlet must have a two-inch inside diameter. If your plumbing is larger than the inlet or outlet o the pump it will only help to increase your flow rate. A larger fluid path means less friction loss from your hose, plumbing, strainers, etc.

Plumbing the Pump for Load & Unload

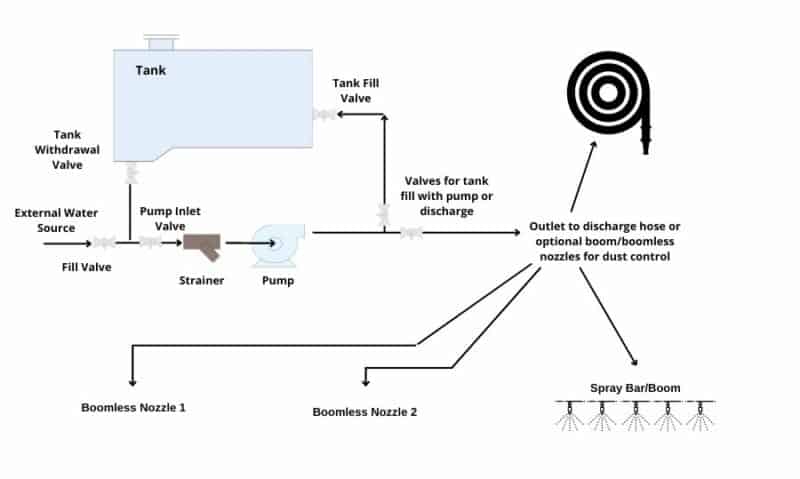

A water truck can be plumbed together virtually any way that will suit you, as long as you have a suction hose that is sized to match the pump inlet. One of the main features you might want is the ability to use the pump to both fill and unload the tank, as well as supply a boom or set of nozzles for dust control.

In the diagram below you can see a very basic plumbing setup that will allow the pump to fill the tank from an excess water source (assuming it is a self-priming pump). Using valves to direct the flow of water, you can easily accomplish this. Remember to always check that your valves prior to the pump are open before running the pump.

To unload the tank, the fill valve shown on the far left would be closed, and the tank withdrawal valve as well as the pump inlet valve would need to be open.

To fill the tank from an external source. The fill valve would be open, the tank withdrawal valve would be closed. On the discharge side, the discharge valve would be closed, and the tank fill valve would be open.

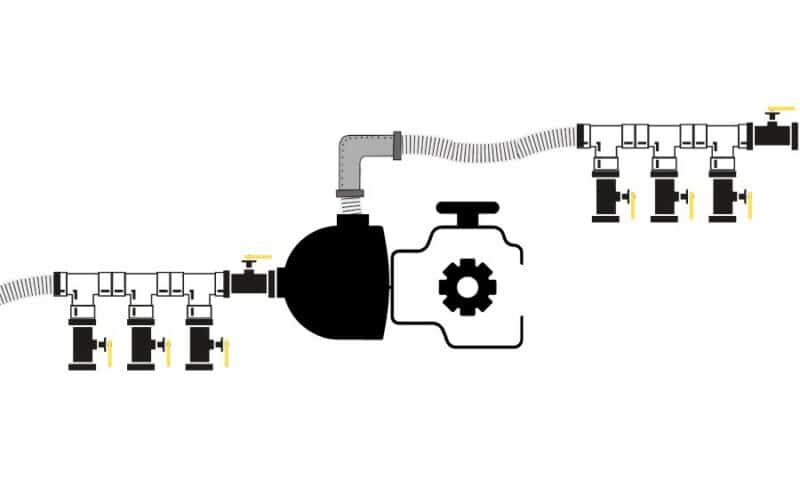

In the diagram, these valves are shown spread all over, but for easy access, you could create a manifold on the inlet and discharge side of the pump that is mounted in a spot that an operator could more easily access without crawling all over the truck.

Plumbing Connections

Cam-lever couplings make it easy to connect multiple sections of the hose or disconnect from your pump when you travel. But for more permanent connections manifold flanges provide an easy way to make changes to plumbing. You can easily replace valves, strainers, or other components without having to unthread pieces from the hose or other fittings. If you are not familiar with this style of fitting, be sure to read this post on manifold flanges.

Suggested Equipment for Simple Water Truck Setup

Pump

There are so many options for water transfer pumps, but if you are looking for an affordable option, Pacer makes a solid poly pump. Paired with the super reliable Honda gas engine, they are great for water transfer and rust will not be an issue. These pumps are self-priming and easy to repair.

The only downside is that they are made from polyester so they don’t handle debris as well as a cast iron pump, but adding a strainer prior to the pump can protect from rocks, sticks, or other solids (remember that your strainer should be at least the same size as the inlet of the pump). The 2-inch pump will move about 150 gallons per minute, while the 3-inch model can move about 300 GPM.

Suction & Discharge Hose Kits

For a complete setup, you will need more plumbing fittings and hoses than provided in these kits, but these kits do include a suction hose and a strainer for pulling water from a lake or lagoon. It also has a lay-flat discharge hose that could be used to transfer water from your truck to another holding tank.