If you’re involved in the agriculture or turf industry, understanding the intricacies of Banjo Manifold Flange Fittings is essential for optimizing your plumbing connections. These fittings, known for their convenience in semi-permanent plumbing scenarios such as sprayers, nurse trailers, and planters, offer a streamlined solution for connecting hoses and rigid plumbing without the need for disassembly.

The sizing of these fittings can be confusing so this guide will clearly explain the different size flanges, the clamps and gaskets that fit them, and how to identify the size of a flange by measuring it.

RELATED: Ag Sprayer Plumbing Diagrams

Understanding Banjo Manifold Flange Fittings

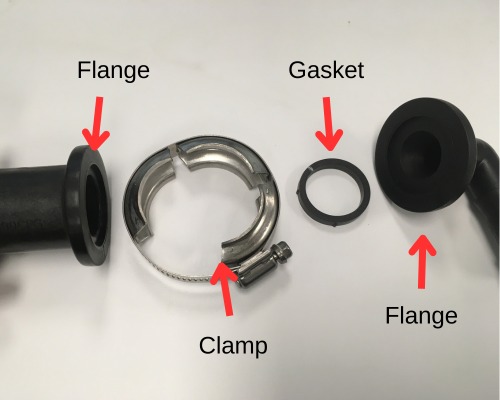

Manifold flange fittings consist of two flanges connected by a clamp with a gasket between them, ensuring a no-drip seal. These are typically made of polyethylene (similar to the Banjo cam-lever couplings), but stainless steel is another option. They are suitable for use with a wide variety of fertilizers and agrochemicals. Their design simplifies maintenance and modifications, providing flexibility to your setup.

Unlike pipe thread, you can remove individual sections of plumbing, valves, strainers, etc., without having to disassemble your entire system. This saves you a huge amount of time and hassle when you need to replace a damaged item or make a change to your current plumbing. They are best used for semi-permanent plumbing scenarios such as the inlet of a sprayer pump or connecting hoses to a flow meter or strainer.

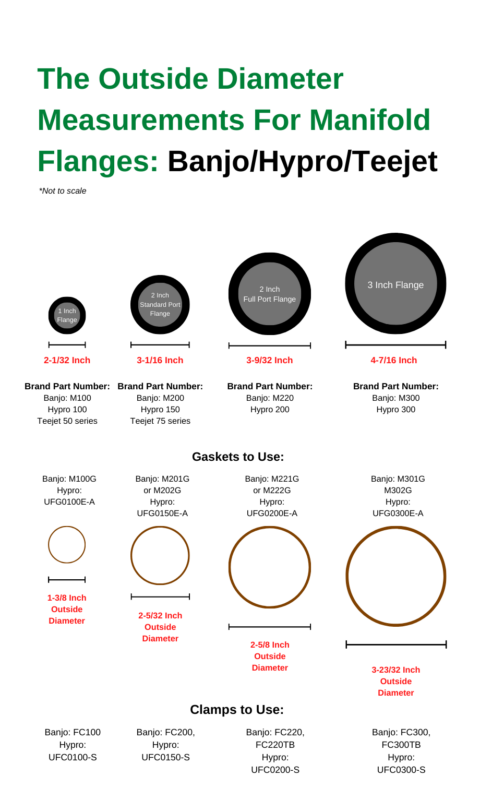

The flanges are connected by a clamp, with a gasket between the two flanges to seal. There are four standard sizes of manifold flange used in the ag/turf world. A variety of different manufacturers make and sell manifold flange fittings, and though they use different numbering systems, they all fit together. This can lead to second-guessing when connecting two pieces that are made by different companies (Banjo, Hypro, Teejet, etc.).

Standard Banjo Flange Sizes

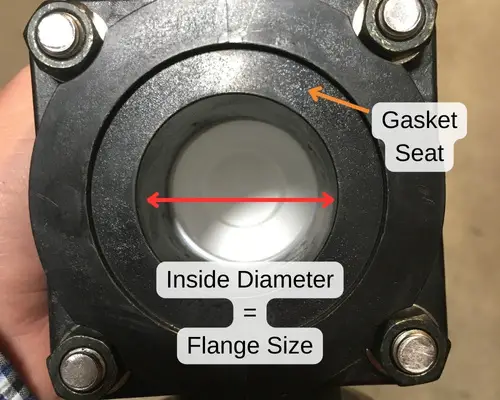

There are four standard sizes for Banjo Manifold Flange Fittings: 1-inch, 1.5-inch (or 2-inch standard port), 2-inch full port, and 3-inch. The key to utilizing these fittings effectively lies in understanding their inside diameter, which is crucial for determining flow capacity. Despite the confusing naming conventions across different manufacturers, such as Banjo, Hypro, and Teejet, compatibility remains straightforward as long as the sizes are correctly identified.

One of the confusing parts is that Banjo calls the 1.5-inch inside diameter flange a 2-inch “standard port” flange and the 2-inch inside diameter flange is referred to as a 2-inch “full port” flange.

Here are the part numbers used by the different companies to refer to the four different manifold sizes and how they match up:

Banjo Manifold Flange, Clamp, & Gasket Part Numbers

| Banjo Flange Size | Banjo Part Number | Hypro Part Number | TeeJet Part Number | Gasket Part Number | Clamp Part Number |

| 1-inch | M100 | 100 | 50 | M100G | FC100 |

| 1.5-inches (2-inch standard port) | M200 | 150 | 75 | M201G | FC200 |

| 2-inch full port | M220 | 200 | NA | M221G | FC220 |

| 3-inch | M300 | 300 | NA | M301G | FC300 |

Identifying Banjo Manifold Flanges

In the image below you can see a 2-inch standard port (1.5 inches inside diameter) flanged elbow. Banjo provides the full part number on the fitting (M200CPG90SH). Banjo uses M200 to refer to their standard port 2-inch fittings. This will mate with other M200 fittings from Banjo as well as #150 fittings from Hypro and #75 fittings from Teejet.

In instances where a part number isn’t visible, measuring the inside diameter of the flange fitting allows for accurate identification. This way you can match flanges correctly, regardless of manufacturer-specific naming.

This chart shows the dimensional measurements of the four different manifold flange sizes:

Connecting Banjo Manifold Flanges

Banjo manifold flange fittings are easy to assemble if you have the proper pieces. Two flanges are connected and sealed with a clamp and gasket. The gasket seats in the recessed area of the flange face, then the gasket fits over the outside of the flanges. The clamp tightens around both flanges and holds them firmly together with the gasket in place.

Benefits of Banjo Manifold Flanges

Manifold flanges have several benefits over other plumbing connections, especially traditional threaded fittings:

- You can remove one fitting from an entire system without unthreading every fitting in the line

- Make changes to your plumbing quickly

- Easily isolate parts that need to be replaced

- No Teflon tape or thread sealer

When to Use Banjo Manifold Flanges

Banjo manifold flanges can be used in almost any industry. They are perfect for sprayer nurse trailers. They make it extremely convenient to make changes to your setup. They will also work for de-icing, pest control systems, and other industrial applications.

They are especially handy when you can use them to install a pump, meter, or any other sprayer component that may need to be replaced. The fittings come in any style you might need such as elbows, hose barbs, or even threaded adapters so they can be used to install any pump or component. When that component needs to be replaced you do not need to unthread a bunch of fittings, simply remove the clamps and slide the piece out of place.

Final Thoughts

Manifold fittings are a time saver and they are easy to work with. The key is to remember that there are four different sizes available and although the part numbers are not identical for each brand/manufacturer, they will mate up just fine as long as you can identify what size you have.

Manifold flanges are superior to pipe thread fittings when you need to occasionally replace components like on sprayers or nurse trailers. They also give you the flexibility to easily add things like inductor tanks and line strainers.