Are you tired of replacing burnt-out solenoid coils or having to rebuild the solenoid valve each spraying season? The choice between solenoid valves and motorized ball valves can make a rather large difference in the reliability of your sprayer and the amount of downtime you encounter.

On a sprayer, Electric ball valves will last longer and have fewer issues than solenoid valves. They are more expensive, but they will usually pay for themselves over time because you will not have to rebuild or replace them.

Having quality sprayer components is vital, so let’s look closer at the details and compare these two types of sprayer valves.

RELATED: How to Control Sprayer Output

Why Electric Ball Valves are Better Than Solenoid Valves for Sprayers

Unlike solenoid valve coils, the motorized actuators on electric ball valves do not have the risk of “burning up”. Solenoid coils require constant electrical current to keep them open or closed, depending on whether you have a normally open or normally closed valve. Resistance will cause the coil to heat up and burn out. Some of the causes are the plunger not operating correctly, wrong voltage, or coil short circuit.

Electric ball valves have a signal or switch wire that tells the motor to turn the ball and when to stop. There is no coil, instead, there is an electric motor that drives the gearbox to turn the ball. The valve actuator/motor is made to be sealed up against moisture or debris. Ball valves also provide a better seal for a longer time, especially when they are flushed out with fresh water or a tank neutralizer and cycled before being stored for a long period of time.

Electronic valves play a huge role in controlling sprayer output. If you want to learn more then be sure to read this article about about electronic sprayer controls.

What is the Difference Between Solenoid Valves and Electric Ball Valves?

The difference between electric ball valves and solenoid valves is in both how the valve functions and how it is actuated (turned on/off).

A solenoid valve is actuated by sending current to the coil on the valve to create a magnetic current that either opens or closes the valve. The valve is closed by a plunger pushing a seal or diaphragm closed. Solenoid valves require constant current to keep them closed (or open but more on this later).

Electric ball valves on the other hand have a motorized actuator sitting on top of a ball valve. The actuator has an electric motor that turns the ball open or closed. The motor has power supplied to it and a signal or switch wire will tell the valve to open or close when the operator flips a switch in the cab.

How a Solenoid Sprayer Valve Works

Solenoid valves are used in numerous industries. In the agriculture world, 12-volt solenoid valves are commonly used on sprayers to remotely control flow to the spray boom. When voltage is supplied to the valve it opens allowing liquid to be sprayed.

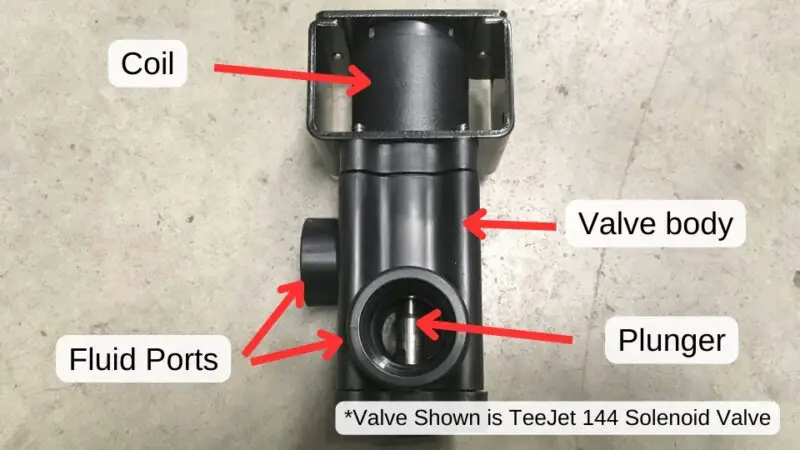

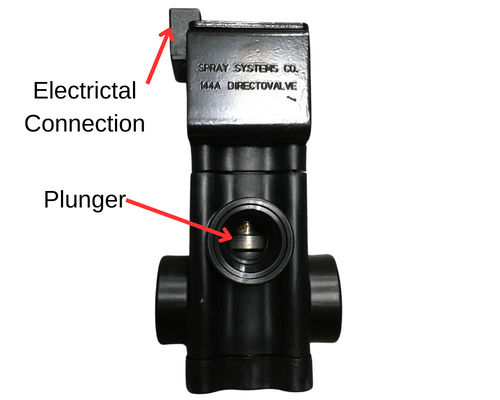

Parts of a Solenoid Valve

The basic components that make up a solenoid valve are the coil, valve body, plunger, spring, and armature. The coil surrounds the armature. Within this armature, you’ll find a plunger and a spring.

Activation

When an electrical current is applied to the solenoid coil, it generates an electromagnetic field. This field interacts with the plunger, causing it to move upwards against the force of the spring.

The upward movement of the plunger is what opens the solenoid valve. This allows the liquid, such as pesticides or fertilizers, to flow through the valve and out the boom when needed.

When the electrical current is cut off, there is no longer a magnetic field acting on the plunger. As a result, the spring forces the plunger back down, firmly closing the valve and stopping the flow of liquids.

Different Types of Solenoid Valves

Solenoid valves come in two primary types: Normally Open and Normally Closed

- Normally Open: A normally open solenoid valve remains open by default and closes when an electrical current is applied.

- Normally Closed: Normally closed solenoid valves are commonly used in agricultural sprayers. They maintain a closed position until an electrical current is applied, opening the valve, and allowing the controlled release of liquids onto crops.

How a Motorized Electric Ball Valve Works

Like a solenoid valve, motorized electric ball valves are used in lots of industries. In the sprayer world, they are usually 12-volt actuated. When a toggle switch is flipped, the motor turns a series of gears to rotate the ball inside the valve.

The actuator is factory set with a specific travel distance so it knows when the ball is in the open or closed position, telling the motor to stop.

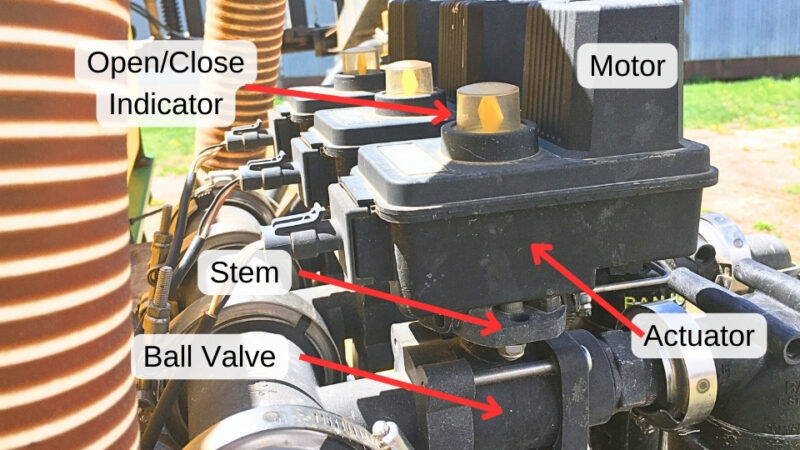

Parts of an Electric Ball Valve

The basic parts of a Motorized ball valve are the actuator, the valve body, the ball, the stem, the motor, and the gears inside. There is typically a fuse inside the actuator as well as other intricate components that allow the ball valve to operate precisely.

Electric Ball Valve Actuation

The actuator on an electric motor sprayer valve is connected to the power supply (battery) and a control console in the sprayer or tractor cab. When a toggle switch on the control console is flipped on, a signal is sent to the actuator to energize the motor and rotate the valve.

The actuator is programmed to rotate the ball the exact distance needed to fully open the valve and tell the motor to stop. When the switch is turned off, then the motor is again energized and it again rotates the ball to the closed position.

Common Solenoid Valve Applications

Solenoid valves are generally used on smaller ag, turf, or garden sprayers. They are used for on/off control for sprayer boom sections, boomless nozzles, and also foam markers. They are simple to connect to a switch box with either weather pack or spade connections. Typical sizes for use on sprayers are ¾ and 1 inch.

They have two main types: normally open and normally closed. The normally open is open until power is supplied and the normally closed is closed until power is supplied.

Common Electric Ball Valve Applications

Ball valves are used on pull-behind and self-propelled sprayers, planters, trucks, and other pieces of equipment. The actuator on an electric ball valve is motorized giving you enough torque to handle larger valves and flow rates. They only require power when the ball is being turned. Solenoid valves require constant power to keep open or closed.

An electric ball valve can be used more easily with different rate controllers and switch boxes. They can also be used as a regulating valve when they are equipped with the right type of actuator. They are used for section control on self-propelled sprayers, planters, water trucks, etc.

Note: If you have been using solenoid valves with a sprayer controller like the TeeJet 744A or similar, you will need to change your wiring to use ball valves.

RELATED: Automatic Sprayer Control Setup

How Long Will A Solenoid Valve Last Compared to A Ball Valve?

If you spray hundreds or even thousands of acres every year, you most likely are well acquainted with electric ball valves, but if you have a small sprayer and do not spray many acres, you still may be frustrated by the number of times you need to repair or replace solenoid valves. Although the initial investment may be greater, you will see a great deal longer life with an electric ball valve.

How to Extend the Life of Your Sprayer Valves

Whether you use a solenoid valve or a ball valve there are steps you can take to prolong the life of the valve:

- Drain your sprayer completely before storing it for winter

- Store valve in open position when not in use

- Unplug the power harness when storing the sprayer (make sure the valve stays in the open position)

- Use RV antifreeze to winterize your system

The Bottomline

Electronic ball valves are better for use on sprayers than solenoid valves. Although solenoid valve technology has advanced to offer a more reliable option, ball valve motors do not suffer from burning out due to the constant electrical current during use. The cost of ball valves is more but they last much longer. If downtime costs you money they will pay for themselves and you will be happier in the long run.