There are endless ways to plumb a nurse trailer or water truck. Everything depends on your situation. Before setting up your sprayer nurse trailer here are several factors to consider.

Tender Trailer Plumbing

The size of your plumbing is the primary factor in determining how fast you can load and unload your sprayer tanks. For agricultural spraying 2 and 3-inch plumbing is common. The hose size refers to the inside diameter of the hose. While it will cost you less to build your system with 2-inch plumbing, 3-inch hose and plumbing will actually accommodate twice as much flow as 2-inch plumbing.

In addition to the hose, the type of fittings you use can have a restriction on your flow rate. It is important to stay consistent with the size of your valves, fittings, and strainers. If your pump is a 2-inch pump and you are using a 2-inch hose, but you have a 1-½ strainer, you are limiting the flow with that strainer. Maintaining a 2-inch inside diameter fluid path throughout will limit the restriction on your flow rate. In fact, you can use 3-inch plumbing with a 2-inch pump and reduce the restriction even more while allowing you to upgrade to a 3-inch pump in the future without replumbing your system.

The plumbing size you ultimately choose can be dictated by the opening in your storage tank. If your tank only has a two-inch bulkhead then you do not want to use a 3-inch pump. The suction or inlet side of your transfer pump needs to be at least the same size as your pump inlet. When starting from scratch be sure to consider whether you want to use 2 or 3-inch plumbing and make sure your tank opening will accommodate that. You can always install a larger bulkhead in your tank in the future if needed.

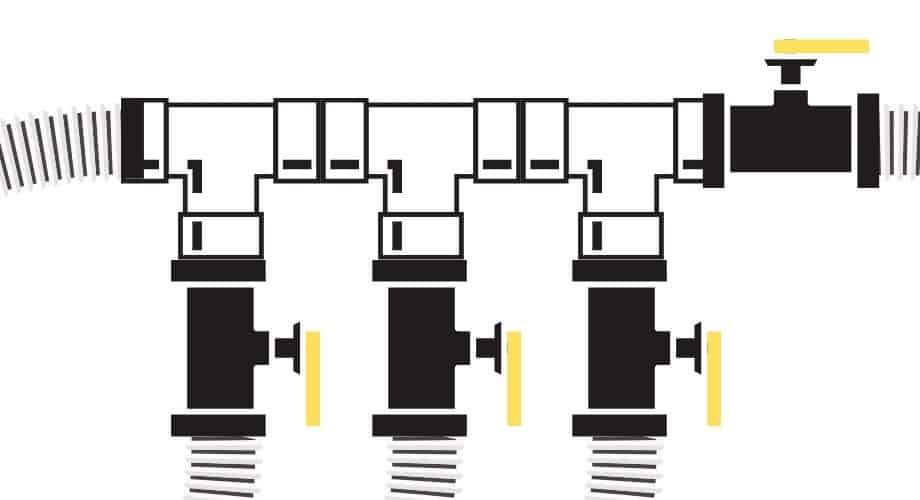

Sprayer Tender Trailer Manifolds

Manifolds give you options and provide convenient centralized access to your valves. They also allow one transfer pump to serve multiple functions. You can also use less feet of hose and avoid valves that are in hard-to-reach places.

Sprayer Trailer Transfer Pump

When it comes to your transfer pump, the inlet and outlet port size of your pump is not the only attribute you should consider. You need to also consider the horsepower you will need, and cast iron vs poly.

Horsepower

Transfer pumps are centrifugal pumps. The amount of horsepower they require depends on many factors including the flow rate, the total head, the weight of the liquid, impeller size, etc. Generally speaking, if you are pumping water, a 2-inch pump with a 5-hp gas engine like a Honda GX160 is plenty. If you want to move fertilizer, 5 hp may be enough depending on the weight of the fertilizer, but a larger engine may be necessary.

3-inch transfer pumps will typically move water with a 6.5 horsepower engine like the Honda GX200, but there are many 3-inch pump options available with a 13-14 HP gas engine to accommodate heavier fertilizers. These are larger pump and engine combinations are designed to move products like 32% and 10-34-0.

Wet vs Dry Pump Seal

Standard centrifugal pump seals are lubricated by whatever liquid is traveling through the pump. The seal of a centrifugal pump is made up of two faces that are pressed together as by a spring. As the pump shaft turns these two faces rub together. This creates heat and without liquid in the pump, the seal can be damaged and the pump will leak.

If a tank is empty or air is being drawn into the pump this can be hard on the seal and eventually cause it to fail. Even a tank that has a good amount of water in it can vortex and air will be drawn into the pump. This is generally accompanied by a change in the sound of the pump and engine as an air bubble goes through the pump.

The best practice is to plumb your setup in a way that your pump runs smoothly with little to no air or potential for it to run dry. Having the proper size suction hose and plumbing will help but sometimes things happen and pump seals will fail. A solution to pump seal failure due to running dry is a wet-seal pump.

Wet-seal pumps have a chamber or reservoir around the seal filled with anti-freeze or a similar product to keep the seal lubricated and cool during operation. Even if the pump is run dry or sucking in a lot of air.

If you are interested in more information about transfer pumps you can view this previous post about centrifugal pump issues and troubleshooting.

Sprayer Transfer Hose

As discussed above, it is important to make sure that you are using a suction hose that is large enough to properly supply your pump with liquid. A suction hose has a metal or plastic coil in it that allows it to maintain its shape under a vacuum. A normal rubber sprayer hose can collapse from the suction created by a centrifugal pump and this will starve the pump and lead to seal failure. You can use a suction hose for the discharge side of your plumbing as well.

Your hoses should be made from materials that are suited for the liquid they will be carrying. There are many different types of hoses: PVC, EPDM, Buna, HDPE, vinyl, etc. They have different attributes and the cost does vary. In addition to chemical resistance, UV resistance, flexibility, and weight of your hose should be considered.

EPDM rubber or poly hoses work well with agrochemicals and fertilizers. EPDM suction and discharge hose also have good UV resistance and flexibility.

Sprayer Tender Trailer Hose reels

Hose reels save space and make handling your hoses much easier. If you plan to use a hose reel then be sure to add an air inlet to blow out the line after you have finished filling your sprayer. This will ensure all the product is out of the reel. Reducing the weight and limiting any spills or clean-up.

Selecting Tanks for Sprayer Tender Trailers

You can find storage tanks for sprayer tender trailers in all shapes and sizes. So regardless of the truck or trailer, you need them to go on you can find something to fit. There are obvious things to consider like how much water you need to haul and the total weight you can haul, but here are several other factors to consider when choosing a tank:

Tank Color – Black tanks eliminate algae growth, but require a sight gauge to see the liquid level.

Tank Sump – There are tank options for flat bottom tanks with a bulkhead on the side or tanks with sumps. These sumps allow the tank to be drained completely. The sump can be in the center or slope to the end of one side of the tank. Keep in mind that tanks with sumps will need to sit on a skid to provide space beneath the tank for the sump, or a hole can be made on the floor of the trailer to accommodate the outlet of the tank.

Tank Baffles – Baffles are a safety feature. They are standard in many large horizontal storage tanks. Their purpose is to disrupt the sloshing of liquid in the tank. This helps reduce braking distance and gives your truck or trailer more stability when hauling large amounts of liquid.

Tank Thickness – The strength of a tank is rated by the weight of the liquid it can hold. It is expressed in pounds per gallon or specific gravity. Most polyethylene tanks are rated for liquids up to a 1.7 specific gravity or 14 lbs/gallon. This is strong enough for starter fertilizer (10-34-0), which is about 11 lbs/gallon.

Chemical Mixing System for Sprayer Trailers

This is the area where sprayer tender trailers can really vary from one to another. There are many chemical induction systems on the market and several different ways to plumb together a mixing system yourself. Here are a few key things to remember when it comes to chemical mixing and inductors.

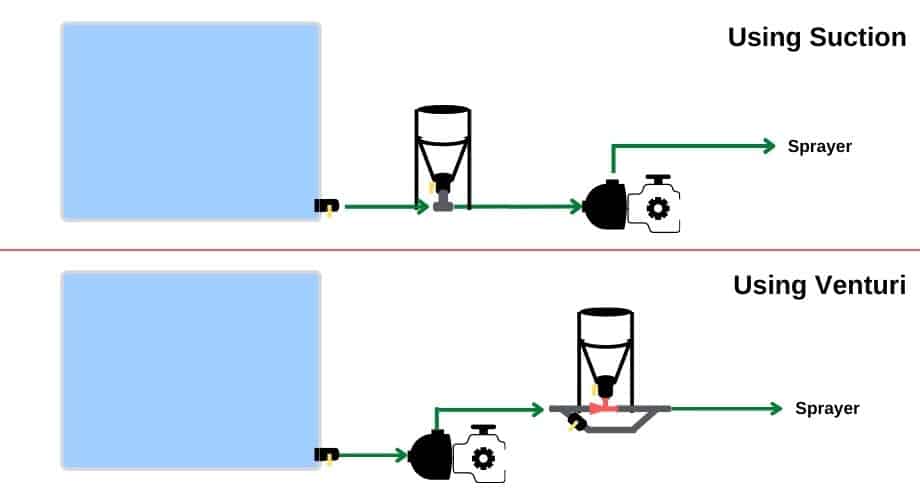

Cone Bottom Tanks: Suction vs Induction

The most common method for adding chemicals to your water is via cone bottom tanks. You can use the suction from your transfer pump to pull in the chemical you add to the cone bottom tank, but this can lead to pump issues, as mentioned earlier.

Using a cone bottom tank with a venturi manifold, you can suck chemicals into your sprayer or storage tank without any chemicals having to travel through your pump. The inductor tank and venturi are downstream from the transfer pump and the velocity of the liquid moving through the venturi generates suction and efficiently draws in the contents you have added to the cone bottom tank. You can read more about inductor tanks and venturi manifolds in this article about inductor tank plumbing.

Chemical Injection

Cone bottom tanks are great for adding products from jugs or bagged dry products. But if you need to add multiple bulk products using 12-volt chemical pumps, you can inject your chemical into a main 2 or 3-inch line directly. Here is what you would need:

- 12-volt chemical pump

- Check valve for each product being injected

- Chemical Meter

- 2 or 3-inch “T’s” to make a manifold for injection points

- 1-inch hose, fittings, and valves

- Pressure gauge for mainline

Instead of pumping the amount needed of your bulk products one at a time into the inductor tank, you can plumb the bulk product directly into your main transfer line downstream of the inductor tank. The check valves are installed at the point the chemical hose meets your main line. This ensures that chemicals will enter the line and nothing will come out when the pump is off.

This type of system is most effective with automatic meters like Dura’s auto batch injection system so you do not have to babysit each chemical pump. Simply enter the amount of product you need and the meter shuts off the pump once that amount is reached.

Best Plumbing Fittings for Sprayer Trailers

You are probably familiar with polypropylene, most of the valves, fittings, and couplers used in the ag world are polypropylene. Poly fittings are recommended over iron, steel, or PVC. Specifically poly manifold flange pipe fittings, but more on those in a moment. They do not rust and have good resistance to most agrochemicals and fertilizers.

In place of standard threaded pipe fittings, you should consider incorporating manifold flange fittings into your setup.

Manifold Flanges

Manifold flanges provide strong, leak-free, connections in your sprayer or sprayer trailer plumbing. In this post, you can see more details on manifold flange sizes. Two or more flange fittings are held together with a clamp and sealed with a gasket. They provide two main advantages over pipe thread fittings.

First, changes can be easily made or fittings replaced by simply removing the clamps and pulling a single fitting out of line. With threaded fittings, you have to unthread full sections of plumbing in order to make changes. Second, because these fittings do not have to be threaded into one another, the inside diameter of your plumbing will be larger throughout your setup. This will maximize your flow rate.

Manifold flanges can be used in any permanent or semi-permanent plumbing scenario. They work great on the inlet or outlet ports of your transfer pump, making it easy to switch your pump or make repairs.

Maximizing Your Flowrate

Using manifold flanges over threaded fittings will help increase your flowrate, but there are other things you can do to limit the flow restrictions created by elbows, T’s, valves, strainers, etc.

Elbows & T’s

90 degree elbows in your plumbing create restrictions on your potential flow rate. The effect is minimal for just one, but if you add up multiple elbows, then your restriction can become significant. Where you can, instead use 45 degree elbows or long radius sweep elbows instead of standard 90 degree elbows.

Valves

A ball valve will not create flow restrictions if completely open and the port through the ball is the same inside diameter as the rest of your plumbing. Some valves may be 2 inch thread or flange but the fluid path inside the ball may be smaller. It is important to make sure that it is full port especially with manifold flanges as they have two different “2” inch sizes of flange. This can cause confusion but you in this article I cover how to measure manifold flanges to make sure you have the full port version.

Strainers

A strainer is likely going to be the biggest restriction in your plumbing, assuming everything else is the same size. You can maximize flow by oversizing strainers and using screens with larger openings or coarser mesh.

Other Sprayer Tender Trailer Options

There are countless equipment options and ways to plumb your trailer. At the end of the day, ease of use and efficiency are the goals. Adding things like step ladders to get on and off the trailer and electric start gas engines to make it easier to start your pumps can make a big difference that is worth the extra cost.