If you have been looking for a chemical sprayer you have likely noticed that in addition to the conventional boom, there are also boomless sprayer options. Naturally, this brings up a good question: what exactly is the difference between a conventional boom and a boomless sprayer?

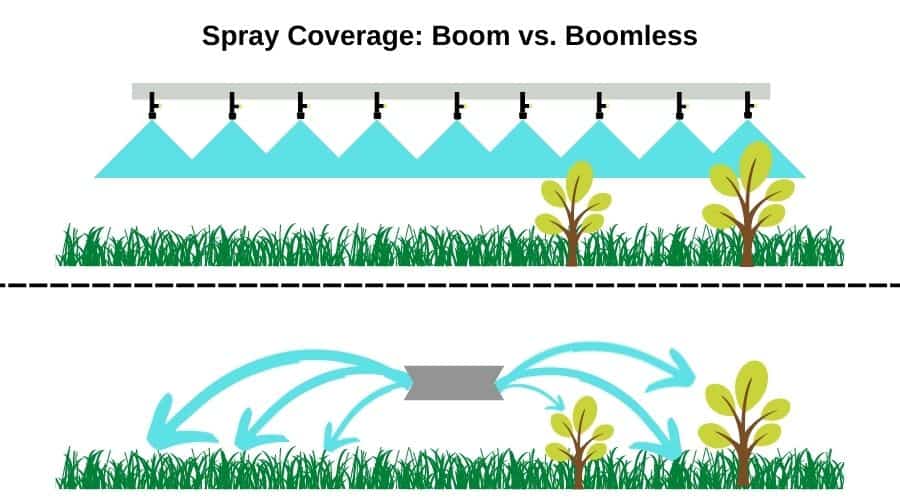

A conventional boom sprayer uses a physical boom structure with multiple nozzles spaced evenly along its length. In contrast, a boomless sprayer relies on one or two nozzles that can project spray over a wide area without the need for a physical boom.

A boom sprayer will offer more precise application but it can be hard to maneuver wide booms around obstacles and on rough terrain. A boomless sprayer is much more versatile and easy to use on rough ground but they do not offer the same even and consistent application that a boom sprayer does.

There are several different applications where each of these sprayer types excels. I have some experience using both types, so let’s run through the pros and cons of each, and help you decide which type of sprayer boom will work best for you.

Differences Between Boom and Boomless Sprayers

Most likely, a conventional sprayer boom is what you think of when you visualize a sprayer boom. It consists of a bar or pipe spanning out evenly on either side of the sprayer with a set of spray nozzles evenly spaced along the entire length of the bar.

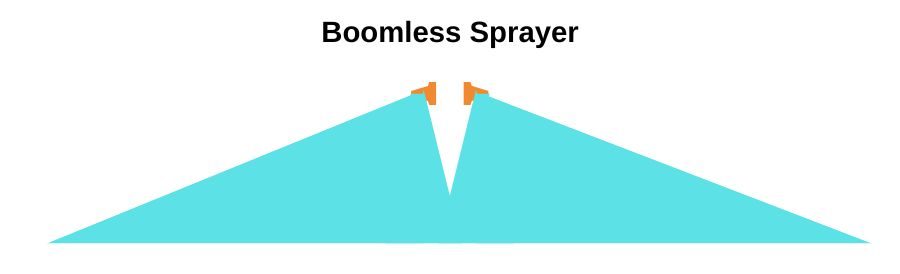

A boomless sprayer is a sprayer that does not use a traditional spray boom to distribute chemicals or other liquids onto crops or fields. Instead, boomless sprayers use a set of specialized high-flow nozzles that are designed to distribute the liquid in a wide, fan-shaped pattern. Typically a single boomless nozzle can cover the same area as several traditional flat fan nozzles that you would find on a boom.

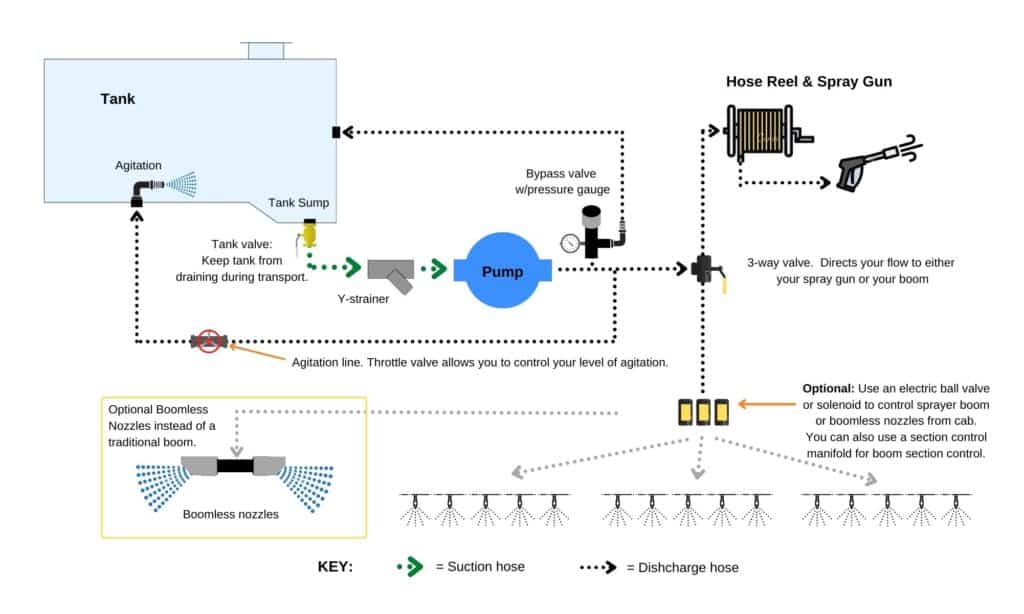

Both boom and boomless sprayers will have a pump, tank, valves, controls, etc. As the name suggests, the style of the boom is the main difference between the two. Below, you can see a simple plumbing setup for a sprayer. Notice that both a standard boom and boomless setup can be used.

What is a Conventional Sprayer Boom?

A conventional sprayer boom is a piece of steel or poly pipe spanning a certain distance, typically at the rear of the sprayer. There are two types of boom: wet and dry. In a “wet” boom the pipe itself carries the liquid to the nozzles, while in a “dry” boom hoses feed the nozzle bodies on the boom pipe. In either case, multiple nozzles are spaced evenly along the boom. These nozzles overlap to provide a consistent spray pattern. The boom height can be adjusted to spray low to the ground, minimizing drift and ensuring good coverage.

What is a Boomless Sprayer?

A boomless sprayer is a sprayer that does not use a traditional spray boom to distribute chemicals or other liquids onto crops or fields. Instead, boomless sprayers use a set of specialized high-flow nozzles that are designed to distribute the liquid in a wide, fan-shaped pattern. Typically a single boomless nozzle can cover the same area as several traditional flat fan nozzles that you would find on a boom.

A “Boomless” sprayer gets its name because it uses nozzles that can cover a wide swath without an actual boom spanning the entire distance being covered. So despite having no boom, or being “boomless”, the sprayer still disperses liquid over a wide swath of land.

There are several different sizes and types of boomless nozzles. They offer a wide range of spray widths and capacities.

Boom Vs Boom Sprayer Diagram

Comparing the Pros and Cons of Boom and Boomless Sprayers

There are definite advantages and disadvantages for each sprayer type. They can both be effective in the right application. Let’s look at the pros and cons of each type.

Pros: Boom Sprayer

- Drift – A conventional boom can be run closer to the ground than boomless nozzles, making wind less of a factor. Especially when you use drift-reducing air induction nozzles that will minimize your drift.

- Nozzle Selection – While there are many sizes and brands of boomless nozzles, there are far more nozzle options for use on spray booms. You can get very precise with the type of spray angle, droplet size, and spray pattern.

- Coverage – Uniformity, and consistency are key attributes of conventional booms. The nozzle at the center or the end of the boom will provide the same droplet size and spray pattern. A boomless nozzle will have less uniform droplet size and coverage over the length of the swath.

Pros: Boomless Sprayer

- Maneuverability – Without a boom, you can easily avoid trees, fences, and other obstacles. You can spray anywhere your tractor or UTV can fit because, without a boom, the sprayer is generally no wider than your wheelbase.

- Less Maintenance – With a conventional spray bar/boom, you have multiple nozzle bodies, tips, hoses, and clamps, not to mention the metal boom arm itself. These components break and wear out. A boomless sprayer replaces all this with just a couple of nozzles and their appropriate plumbing. This substantially reduces the wearable parts on your sprayer.

- Less Storage Space – A boom sprayer, especially a large one, requires a lot of space in a garage or shop. A sprayer using boomless nozzles instead of a boom will take less space to store when not in use.

- Cost – The cost savings from a boomless sprayer can be significant. For example, say you want to add a boom to your sprayer that will cover a width of 30 ft. A conventional boom that spans 30 feet can cost easily over $1000, and that does not include freight costs. On the other hand, adding some boomless nozzles that will cover 30 feet is less than $300.

Cons: Boom Sprayer

- Maneuverability – Unlike a boomless sprayer, where you basically can go anywhere your ATV/tractor/truck and go, a boom sprayer is limited by its width. Boom sprayers are limited to open areas and reasonably level ground.

- Wear & Tear – When one side of the boom goes up, the other goes down. When your sprayer hits a hold or ditch, the boom will drop in height. This creates the potential for damage to the boom. With a boomless sprayer, this is virtually never an issue.

- Storage – Depending on the size of your boom, you may require a lot more storage space compared to a boomless sprayer.

Cons: Boomless Sprayer

- Drift – The nozzles used on boomless sprayers produce a larger droplet size. Similar to when you put your thumb over a garden hose. Larger droplets tend to result in less drift. So why is this a disadvantage? In perfect conditions, the large droplets from a boomless nozzle will produce less drift. However, boomless nozzles can be more affected by wind than flat fan nozzles on a boom. The fluid from a boomless nozzle spends more time traveling through the air than the fluid sprayed from nozzles on a conventional boom, so there is a greater chance for the spray pattern to be altered.

- Coverage – they do not provide coverage as uniform as a boom sprayer. Each nozzle will have an application chart that shows the flow rates that can be achieved at certain pressures. Going outside of these pressure ranges will give you either an uneven pattern or reduced coverage. Fields with tall weeds, trees, shrubs, or other obstacles, can create coverage issues for a boomless sprayer. Boomless nozzles spray horizontally, whereas boom sprayer nozzles are directed straight down to the surface. Therefore, the fluid from the nozzles can be “blocked” and not cover areas behind obstructions. If your application requires precise and uniform coverage, you will likely still need a conventional boom.

Should I Use a Boom or Boomless Sprayer?

This is the million-dollar question. Again, this ultimately comes down to the specific type of spraying you will be doing. So here are the types of scenarios when a boom sprayer will work best and when a boomless sprayer will likely be the better option.

When to Use a Boom Sprayer

Any time you are spraying row crops, a boom sprayer is the better option. The precision and uniform coverage required for spraying things like corn, soybeans, wheat, etc., requires a conventional spray boom.

There are also many different chemical products used and they each may require different spray nozzles. A conventional boom allows for the use of many different types of nozzles.

A boom sprayer is going to be the best option in scenarios that will require a small droplet and even coverage on the plant surface to kill the weed.

When to Use a Boomless Sprayer

One of the most popular uses for boomless sprayers is pasture spraying. Pasture land tends to be rougher ground than farmland so the maneuverability of a boomless sprayer makes it much more desirable than a boom sprayer.

Boomless sprayers also work great for large lawns, parks, and food plots. The ability to transport a boomless sprayer more easily than one with a boom makes them ideal for farmers, ranchers, or hunters who need to spray remote pasture or food plots.

Boomless nozzles come in a variety of different sizes, so they can be used for many different spraying jobs. The flow rates of these nozzles range from about 1 to 40 GPM. Depending on your speed you can easily apply rates of 5-100 gallons per acre. This range makes them great not just for ag and turf but also high volume applications like spraying anti-ice on roads and dust control.

Boomless sprayers are also ideal for dust control and de-ice applications. These tasks don’t require fine droplets or the precise coverage you get with a boom sprayer. High-flow nozzles allow you to travel at higher speeds. Without the boom, your sprayer can travel down roads or parking lots without issue.

Final Thoughts

Boomless sprayers and boom sprayers have distinct differences. Choosing which one will work best for you will depend on your applications and budget. If you would like more information, you can view this post on boomless sprayer nozzles.