If you are looking for a 12-volt sprayer pump you have probably searched online to find one. As you sort through the available options, you come across two types: demand and bypass. But, what the heck is the difference and which one do I need for my sprayer?

The difference between the demand and bypass style 12-volt sprayer pumps is a pressure switch. A demand pump has a pressure switch while a bypass pump does not. The demand-style pumps will shut off when the pump outlet is closed. A bypass pump will continue to run unless power to the motor is switched off.

The purpose of these two different pump styles is to fit different applications. Let’s look at the specifics of each type and how they are typically used.

The difference between a demand pump and a bypass pump

When it comes to 12-volt diaphragm pumps, using a demand style or a bypass style pump will affect the operation of your sprayer. While the pumping mechanism is the same, these two types of pumps differ in one important way.

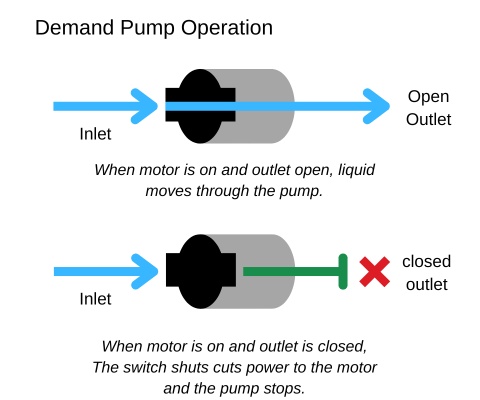

A demand-style pump has a pressure switch. A bypass pump does not. The pressure switch is used to control power to the motor. The switch is set at a specific psi. When the operating pressure inside the pump/sprayer reaches this psi, the switch is activated, cutting power to the motor.

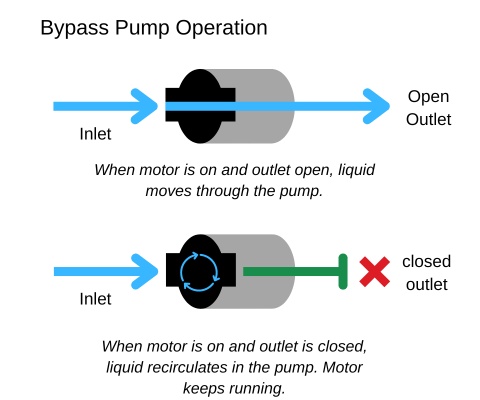

In comparison, a bypass pump will run as long as power is provided to the motor. It is called a “bypass” pump because if the pump outlet is closed, it will continue to circulate fluid internally. Meaning, instead of trying to continue to bring in more fluid until it bursts, the pump can run safely while the outlet is closed.

So now we know the technical difference, but how are these pumps used on a sprayer? Let’s look at these two types in more detail and explain how they function and when to use them.

Demand Style Diaphragm Pump Operation

Demand-style pumps are designed to automatically start and stop based on the opening and closing of your sprayer wand. When the pressure in the system drops (when you pull the trigger on your spray wand), the switch “turns on” providing power to the motor. This results in the pump moving fluid out of the spray nozzle and allowing your sprayer to function.

When you release the trigger, the pressure inside the sprayer hose increases. Very quickly it will reach the set pressure and the switch will cut off power to the motor. The motor will remain off until you pull the trigger on the spray wand.

The demand switch feature is useful in many scenarios but is uniquely suited for a spot sprayer. A demand pump that only runs when you need it. So if you are relying on a battery to power your sprayer, a demand pump is much more valuable than a pump that will run continuously. With longer battery life you can spray more before you must stop to recharge.

This is less of a concern if you’re running your sprayer off a vehicle battery, such as an ATV or UTV, as these vehicles have alternators to keep your battery charged. However, if the pump only runs when you need it you will typically have a longer lifespan because there will be less wear and tear on the parts.

Related: 12-Volt Pump Disassembly Guide

Regulating Flow on a Demand Pump

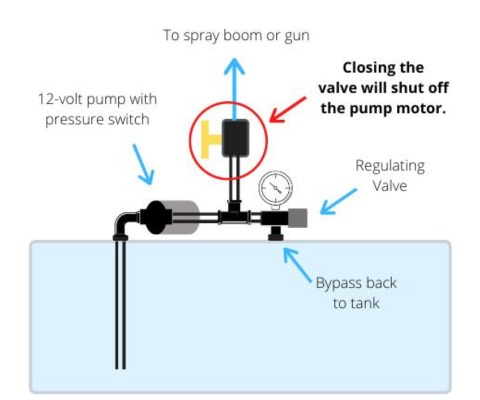

One aspect of demand pumps that can cause problems for users is their tendency to cycle on and off. This occurs when the system’s pressure reaches the switch’s shut-off setting. Then, when the motor is off, the pressure in the sprayer drops, and the switch restores power to the motor. This increases pressure again until again, the switch is tripped and the motor is shut off.

This happens over and over rapidly. It not only makes your sprayer ineffective, but it can burn out the motor and the switch. This typically occurs when the pump is too large for the application or when you change the size of the spray nozzle. A smaller nozzle can result in an increase in pressure, thus tripping the switch.

This can be avoided by using a regulating valve to maintain constant pressure in the system. This is an important aspect of a sprayer so I wrote an entire page just explaining why pump cycling/surging happens and what to do about it.

Bypass Style Diaphragm Pump Operation

Bypass-style pumps continuously run once powered on but redirect the flow within the pump when the discharge nozzle is closed. This internal circulation prevents damage to the pump or sprayer due to over-pressurization.

Comparing Demand & Bypass 12-Volt Pumps on Sprayers

Demand Pump Advantages

- Energy Efficiency: These pumps only operate when necessary, conserving battery life.

- Ease of Use: Automatic operation eliminates the need for manual switches.

Bypass Pump Advantages

- No pulsing: These pumps do not have a pressure switch that shuts off the motor. They run consistently as long as there is power to the motor.

Demand Pump Disadvantages

- Pump Cycling: Without proper regulation or nozzle size, these pumps can pulse, surge, or cycle on and off rapidly. This leads to premature switch and motor failure.

- Wear and Tear: The micro switch relay will only last so long. Eventually, the switch will wear out. Rapid on and off of the motor builds heat and can burn out the motor.

Related: 12-Volt Pump Troubleshooting

Bypass Pump Disadvantages

- Battery Use: A constant running motor can drain the battery faster.

- Requires valves or switches: because the pump will not shut off when the spray wand is closed, you need a valve or switch to close flow or shut off the pump.

Which One Should I Use?

The choice between a demand and bypass pump largely depends on the specific application. You would use a demand-style pump whatever you want to be able to shut off the pump simply by closing a valve on the discharge side or by letting go of the trigger on a spray wand.

Conversely, a bypass pump could be used when you want constant flow for an extended period. Especially if you don’t want to hassle with pressure regulators or the possibility of a switch being tripped.

Here are several scenarios where you would want to use a demand-style 12 V pump:

- Spot sprayer for turf or garden

- Sinks in cabins or RVs

- Small boom sprayers

Here are some scenarios where a bypass-style 12-volt diaphragm pump would be better suited:

- Low-volume transfer of chemicals

- Remote watering systems, irrigation

- Cleaning and Sanitation

- Food and Beverage Processing

In conclusion, when choosing between demand and bypass style 12-volt diaphragm pumps for lawn or garden sprayers, consider the specific needs of your application, including the desired spray patterns, frequency of use, and whether constant pressure or variable flow is more critical. Both styles offer distinct advantages, but understanding their operational differences is key to selecting the right pump for your spraying needs.

For more information, be sure to read the full 12-volt pump guide.