Whether you are a homeowner or lawn care professional, caring for a large property can take time. Especially if you need to spray often. This work requires more than a hand spray or backpack sprayer. A Spot sprayer can provide you with the increased capability that you need to stay on top of things like weeds, diseases, insects, or other pests.

What is a Spot Sprayer?

Spot sprayer is any sprayer that is designed to apply a liquid to specific areas via a spray wand or spray gun. Although a hand pump sprayer or backpack spray are used in similar applications, a spot sprayer generally has a much larger capacity tank and an electric pump. Due to their size, spot sprayers are commonly used on ATVs, UTVs, mowers, trucks, golf carts, etc.

Parts of a Spot Sprayer

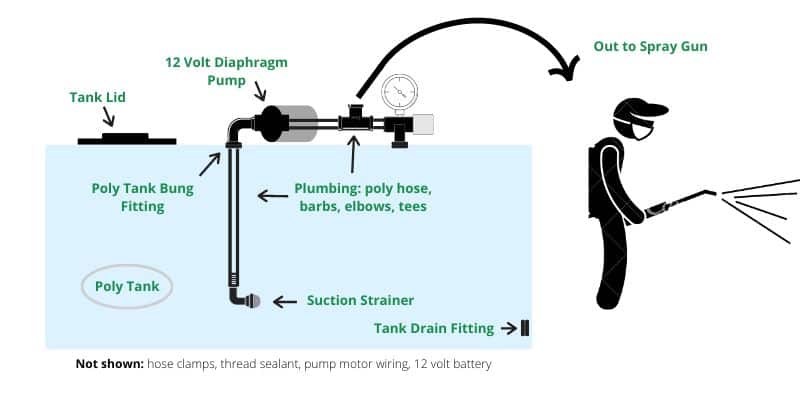

Typical spot sprayers consist of a tank, a 12-volt diaphragm pump, a short length of hose, and a spray wand. Depending on the manufacturer spot sprayers may have a regulating valve, pressure gauge, and strainer. More advanced spot sprayer setups may have a small manifold with valves to direct flow to the spray wand or an optional sprayer boom.

Basic Parts of a Spot Sprayer:

- Tank

- 12-volt pump

- Spray wand

- Regulating valve

- Hose

- Strainer

- Pressure gauge

Looking to build your own sprayer? Be sure to check out this guide that walks you through building a sprayer yourself.

How Does a Spot Sprayer Work?

Understanding how something works is the first step to knowing how to fix it, should something go wrong. Because a spot sprayer involves a pump, when a sprayer is not working, it can be difficult to isolate the problem.

When you turn on your spot sprayer the pump creates suction that pulls the liquid through the suction hose and forces it out of the discharge hose and through the spray wand. For this to happen all parts of the sprayer must function properly.

- There must not be cracks in the suction hose.

- All hose clamps and connections must be airtight

- Internal components of the pump must be undamaged or overly worn.

- Strainers not plugged.

- Proper voltage to the motor.

- The pressure switch needs to be functioning properly.

- The regulating valve must be functioning properly if used.

All of these things are taken for granted on a new sprayer but when you combine the use of chemicals and normal wear, one or more of these things may become an issue.

Therefore, it is advisable to check your components often and properly maintain the sprayer. This involves flushing the sprayer and winterizing it during the off-season. A winterization guide is available in this article about 12-volt sprayers.

Troubleshooting a sprayer can be a tedious process. That is why I wrote a full troubleshooting guide for spot sprayers.

Spot Sprayer Pump

The main component of any spot sprayer is the pump. The specific type of pump used on the majority of spot sprayers is a 12-volt diaphragm pump. This type of pump is used because it can be powered by a battery which makes it more mobile than a 110-volt pump and more affordable and less complicated than a gas engine drive pump.

Travel pumps are relatively low flow ranging from 1 to 5 gallons per minute and they produce 40 to 60 psi. Central pumps are capable of higher pressures but they are usually not necessary for spot sprayer applications.

12-volt pump types that are used on spot sprayers also contain a pressure switch. This type of pump is called the demand pump. You can read my full article on 12-volt pump troubleshooting that explains this in detail, but basically, the demand pump turns on when you pull the trigger on the spray wand and shuts off when you release the trigger. This is ideal for spot spray applications because your pump motor will not have to run constantly and drain your battery or risk heating up.

I have used a Shurflo demand-style pump on my spot sprayer for years and it works great.

Different Types of Spot Sprayers

There are many different varieties of spot sprayers. Some are designed to fit on specific pieces of equipment like ATVs, UTVs, lawnmowers, etc. Most are fairly universal with a similarly shaped tank with the pump on top. They differ in tank size and shape pump capacity, Pressure, hose length, and the trigger gun/want to type, as well as what type of material all these components are made from.

There are not necessarily any official categories associated with spot sprayer types. However, if you were to browse the selections available you will notice several different price points and model numbers. The differences between these sprayers can seem arbitrary but the subtle differences do make a difference in the function and effectiveness of the sprayer. Let’s look at what the different variations mean in terms of sprayer performance.

Spot Sprayer Pump Size

The first difference between spot sprayers to take note of is the size of the pump. typically 12-volt pumps used for spot sprayers range from 1 to 5 gal per minute and they produce pressures of about 40 to 60 PSI. Not to say that some don’t produce higher flow rates or pressure but these are the most common.

Does the pump flow rate and pressure affect my spraying?

The flow rate of the pump is the maximum output per minute that you can achieve when spraying. however, your nozzle size ultimately determines the per-minute output of your sprayer. For example, if you are spot sprayer pump can produce 2 gallons of flow per minute, but your nozzle only has a capacity of 0.4 gallons per minute then your output will only be point 4 gallons per minute.

So, when considering what size pump you need on your spot sprayer is important to first consider how much output you need for your application. If you only need 4 gallons per minute then there is not much sense to buy a spot sprayer with a 4 gallons per minute pump.

Why then do some spots prayers come with large pumps?

Spots prayers are generally made to be used with a single handgun and there are not many applications where we need to put out 5 gallons per minute. However, most manufacturers build their spots for years with an option to add a small boom. this way the pump is large enough to supply all the nozzles on your spray boat if you decide to use one.

The other aspect of pump “size” is pressure. The most common use spot prayers are generally herbicide applications and for this an operating pressure of 30 to 60 PSI is adequate. In fact, sprayer nozzles are color-coded by how much flow they will produce at 40 PSI. Sprayer nozzles are the most important part of any sprayer and if you are new to spraying be sure to check out my article on the most common sprayer nozzle questions.

Spot Sprayer Tank

The size of the spot sprayer tank is one of the most obvious differences to notice. Begin most common spot sprayers are in the 15 to 25 gal range, but there are many different sizes and shapes on the market. Choosing what size is best for you requires knowing how much area you cover and what your application rate will be.

Let’s say you spray one acre and you want to apply a rate of 10 gallons per acre. In this example, a 15-gallon sprayer tank will be plenty large. Things get a little complicated calculating area for spot spraying due to the inconsistent and sporadic nature of spot spray applications. It’s hard to know exactly how much area you need to cover and it’s hard to pinpoint an exact rate when using a spray wand.

This is a topic that requires a lot of explanation and that is why I wrote a separate article that goes into more detail about choosing a sprayer size.

Spray Gun & Nozzle Type

At first glance, it may not seem like there is much difference between two separate sprayer wands. The truth is that the sprayer wand and nozzle are probably the portions of the sprayer that you should consider more than anything else. After all, the spray wand is the part of the sprayer that you will physically interact with and the spray nozzle controls the sprayer’s output, droplet size, and spray distance.

When it comes to the spray wand, you want a wand that is easy to use, durable, and ergonomic. A heavy-duty spray wand may be more durable but it will be heavier, and this can become very hard to use for a long period of time. Grip strength can go very fast if you have to hold a trigger on a spray gun for an hour.

As discussed above sprayer nozzle is the most important part of a sprayer so it is important that you are taking this into account when buying a spot sprayer. Does the nozzle that comes with the sprayer produce the type of spray pattern that you want and is it the correct size for your application rate?

You can find detailed information in this article on different sprayer nozzle types. Personally, I prefer to use an adjustable nozzle on my spot sprayer. This is just 1 oz of 40 G that provides me with a solid stream that can spray about 20 to 30 feet and be Adjusted to spray and a wider cone pattern to provide good coverage up close.

Spot Sprayer Controls

Very basic spot prayers do not have any type of controls or valves on them. You simply turn on the pump pull the trigger and start spraying. But with larger demand style pumps there is a need for a regulating valve. A demand pump that is too large for your spray nozzle will cycle on and off (see the video below).

A regulating valve bypasses the excess flow and maintains a constant operating pressure so your pump does not cycle. This feature is a must if you want a higher volume pump or might ever use a small spray boom with your spot sprayer.

Video of Basic Spot Sprayer Controls:

Spot Sprayer Materials

One final thing to consider when looking for a spot sprayer is it type of materials that it is made out of. this is pretty easy because the vast majority of spot sprayers will be constructed with fertilizers and herbicides in mind, therefore they are made out of poly tanks EPDM Rubber hose, sprayer wands that are poly or nylon, and pumps made from plastic components and materials that hold up to a chemical residue.

It is a good idea to note there are some made for specific uses and may have components made from materials less suited for your application. For example, some sprayers have brass spray tips or spray wands and you might be using a fertilizer or some other chemical that might not be compatible with brass.

The Benefits of a Spot Sprayer

A spot sprayer is designed for similar jobs to a hand sprayer or backpack sprayer but has many advantages over these smaller, less expensive sprayer types. The main benefits of a spot sprayer are mobility, capacity, and consistency.

Mobility

Lugging around a backpack sprayer is a chore especially if you have a lot of ground to cover. A spot sprayer gives you the same access and flexibility as a backpack sprayer without fatigue from carrying it around. You just need an ATV, Mower, Truck, etc.

Capacity

With a spot sprayer, you do not have the same limit on capacity as a hand sprayer or backpack sprayer. You can spray more acres without having to refill. This makes you much more efficient.

Consistent Spray

A spot sprayer provides a consistent sprayer. There is no need to “pump up” your sprayer to achieve the desired pressure. This means that your spray pattern remains the same as long as you are operating at the same pressure. You will see better results and also be able to maintain a more consistent application across your field or yard.

How to Use a Spot Sprayer

A spot sprayer is simple to use. The operator can either spray consistently as they drive to completely cover areas of land or they can spray selectively. For example, it is common with a spot sprayer that you might be targeting a specific weed, like a thistle or velvet leaf, and spraying these plants when you see them.

If you have not used a spot sprayer before, calibrating your sprayer is helpful to find out how much chemical you need to mix in your sprayer. Be sure to read this article about sprayer calibration to learn more.

What Can a Spot Sprayer Be Used For?

A spot sprayer is a great option for large lawns, pastures, food plots, and commercial properties. They allow the user to reach tight spaces or areas that are not accessible with a boom sprayer while providing more capacity than a backpack sprayer or hand sprayer.

Spot sprayers can be used for many other applications outside of spraying herbicides:

- Pest control

- Dust abatement

- Liquid de-ice

- Cleaning

- Fertilizer

They are also very versatile, you can easily add a boom to your spot sprayer if the need arises in the future. This makes a spot sprayer a great option if you are just starting to do your own spraying.

Suggested Products

- Pump: Shurflo 2088 Series, 3.5 GPM

- Tank: Ace Roto-Mold 14 Gallon or 25-Gallon Tank

- Hose: EPDM Rubber 3/8 Inc Hose

- Spray Wand: Gunjet 30L & 18 Inch Extension

- Spray Nozzle: Teejet Adjustable Nozzle