Concrete and asphalt are durable materials, but they are not immune to wear and tear. Moisture, UV rays, stains, chemicals, and other elements can break down your driveway over time resulting in costly repairs. Sealers and coatings are often applied to driveways to protect them from.

Applying a sealer effectively requires the right equipment to do it safely, effectively, and efficiently. Hand pump sprayers will work for these jobs in most scenarios. However, it is important to note that the specific sprayer to use will depend on many factors. This includes the type of sealer you are going to apply, the size of the job, and the type of driveway.

In this guide, we’ll explore the types of sprayers used to seal concrete and coat asphalt.

Understanding Difference in Concrete Sealing & Seal Coating Sprayers

Sealcoating and concrete sealing are both methods used to protect driveways, parking lots, airports, roads, etc. They help to increase the lifespan and enhance the appearance of these surfaces. Different liquids are used for different surfaces and they require different sprayers to apply them.

Sealcoating is a method used on asphalt surfaces. It involves spraying a protective coating on asphalt surfaces. This coating is a coal tar or other asphalt-based liquid.

Concrete sealing, as the name implies, is used on concrete surfaces such as driveways, sidewalks, etc. It provides protection to concrete from UV rays, water, chemicals, and other elements. There are different liquids used, including but not limited to penetrating sealers (silanes, siloxanes, silicates, and siliconates), and polyurethanes.

The liquids used vary in viscosity and chemical makeup. Certain products are less compatible with different materials than others. This makes selecting a sprayer very important and to find the right one you first need to identify the liquid you will use. When you know the liquid that you will use, you can identify the chemical makeup of that product and then identify the materials (rubber, metals, plastics, poly, etc.) that will hold up to that liquid.

Different Sprayers For Concrete Sealers

There are two primary types of sprayers used for sealing and coating driveways. There are sprayers for sealing concrete. These apply water-based sealers, polyurethanes, and other concrete sealing products. The other type is a seal coat machine that is used for seal coating asphalt.

Another big difference between sprayer types will be the size of the sprayer. The size you need is determined by the amount of square footage that you need to cover and whether you are a homeowner Who needs to seal their driveway or a professional who will be using this equipment often.

Handheld Pump Sprayers

- Features: Handheld pump sprayers are small and portable. They are 1-3 gallons in capacity and the operator manually pumps a handle to build pressure in the tank. The application is done by hand with a spray wand.

- Advantages: Hand pump sprayers are affordable and easy to use. They are perfect for small to medium-sized projects. No special training or skill is needed to operate.

- Disadvantages: These sprayers do have limited capacity, which means you might be refilling frequently for larger areas. These sprayers can be physically taxing if used all day. There are better options for large commercial projects.

One vital factor to consider when using a hand pump sprayer is to ensure that the seals and other sprayer components are compatible with the product you are going to use. There is a very diverse group of liquids that are used to seal concrete. There are acrylic sealers, silicate sealers, epoxy sealers, polyurethane sealers, silicone sealers, and more.

Poly sprayers with Viton seals will work with most products but sprayers also use nylon, EPDM, nitrile (buna), PVC, and other materials for hoses, spray wands, seals, and tanks. Some products might have adverse effects on certain materials. This will cause them to wear out prematurely and begin to leak or lock up. Some negative effects might occur quite quickly. For example, an acetone product will be very hard on Viton, Buna, and PVC. Nylon and EPDM are preferred for acetone resistance.

Sometimes it is hard to determine what sprayer will work best with a specific product. Manufacturer guidelines can be pretty broad. It may take some trial and error to find one that will last. This can get expensive if you have to keep buying new sprayers to try.

I did some research to try and determine specific hand pump sprayer models that will work with a wide variety of products. Here is what I found out:

- Budget Option for Water-Based Sealers: Solo Home & Garden Sprayer

- Acetone Sealers: Sprayers Plus 20 ACT

- Xylene: Solo 456HD

- Heavy Duty Option: Chapin Industrial 1949

Hand pump sprayers are versatile tools. They can be used for many different jobs. I have written a complete guide for hand pump sprayers, including how to troubleshoot and repair them:

Backpack Sprayers

- Features: Similar to hand pump sprayers they are worn like a backpack. They are commonly manually operated but there are battery-powered pump versions available. They come equipped with a hose, a wand, and a nozzle. The most common size offers a four-gallon capacity.

- Advantages: When used properly a backpack sprayer can make you more efficient. They do tend to offer more capacity than hand pump sprayers. There is less bending over with a backpack sprayer, as you can pump the handle while spraying and standing up.

- Disadvantages: They can be heavy when they are full. Spraying with them for a long period of time is physically taxing.

Like hand pump sprayers, you need to make certain that your backpack sprayer is compatible with the product you are spraying. If you are looking for help with your backpack sprayer, check out these additional resources:

Commercial Sprayers for Concrete Sealers

Commercial concrete sealers come in many forms. They can be pull-type sprayers or mounted in a truck or other vehicle. Instead of a spray wand, the sealer is applied via a spray boom with multiple evenly spaced nozzles. These are only used when there is a very large area to cover, like a parking lot or large warehouse floor.

- Features: large capacity tanks, large engine-driven pumps, and industrial grade hose.

- Advantages: Ability to work longer and faster, more efficiently.

- Disadvantages: Expensive and heavy to transport. Overkill for small projects.

Example:

Seal Coat Sprayers

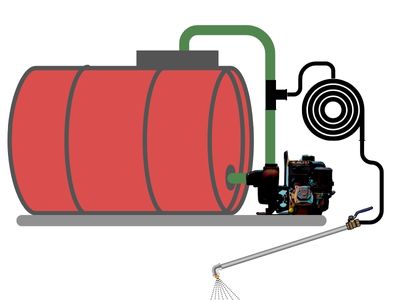

Contractors use a specific type of sprayer to apply seal coat to asphalt surfaces. The sprayer is similar to large skid sprayers used to apply fertilizer and pesticide, but because of the volume that is applied and the characteristics of the liquid, the sprayer is constructed of different components. The primary difference is the materials that the components are made from and the size of the components.

Basic Sealcoat Sprayer Parts

This is a basic list, for a full list of parts to build a simple sealcoat sprayer take a look at this DIY sealcoat sprayer guide.

Tank

The sealcoat sprayer tank is a large container that holds the sealant material. It is usually truck or trailer-mounted. The tank is commonly constructed of steel, but polyethylene tanks may be used with some products.

The typical tank capacity will range from a hundred to over a thousand gallons, depending on the size and scope of the job.

Agitation

The sealcoat mixture must be kept properly mixed in order to get a consistently even layer when applied. A seal coat sprayer can be agitated by using the pump on the sprayer to recirculate the liquid.

Mechanical agitation is also used for mixtures that have solids that can settle out in the bottom of the tank. Mechanical agitation involves large paddles on a reel inside the tank that can be manually turned by a lever on the outside of the tank or with a motor.

Pump System

A seal coat sprayer typically utilizes A gas engine drive cast-iron centrifugal pump. The pump is used to apply the seal coating and also for agitation and loading the tank.

A system of hoses and valves is installed with the pump in order to direct flow to agitate the tank, fill the tank from external barrels or totes, and actually apply the liquid through the spray wand. A strainer filters out debris and large pieces of sediment that can plug the sprayer tips.

Hose and Sprayer Wand

A spray wand is used by the operator to apply the sealant to the asphalt surface. The spray wand is essentially a ½ or ¾ inch steel pipe with an elbow on the end. A cap or quick coupler secures a spray nozzle into the elbow. The nozzle controls the flow of the liquid. Nozzles can be changed to increase or reduce the amount of liquid if needed. Valves can also be incorporated into the spray wand to shut off flow when necessary.

Heavy-duty trigger wands, like the type used for lawn and turf care, can be used to give the operator more precise control. A trigger wand is typically lighter weight and the spray can be sprayed and shut off as needed.

Sealcoat trigger spray gun: TeeJet 43

Nozzles

The sprayer nozzle is a small piece of the puzzle but it has an important job. It disperses the sealing liquid in a uniform and consistent pattern. Without the tip/nozzle, it would be nearly impossible to get the desired result of a clean, even, and effective coating of sealer on the surface.

Sizing the nozzle is key. This may not be the same for everyone. The pace at which you work and the thickness of the coating you want to apply factor into selecting the nozzle size. The typical nozzle sizes used will provide flow rates of about 1-5 gpm at about 40 psi. Getting this range of flow rates will require using different nozzles.

Spray Bar (Optional)

In some cases, contractors may elect to use a spray bar instead of or in addition to a wand. The spray bar has multiple nozzles evenly spaced, allowing them to cover a larger area in a single pass. This may be used for larger, open areas like parking lots.

Final Thought

The right equipment makes the job much easier. Concrete sealers and asphalt coating liquids can be tough on sprayers. Especially if they are built with materials that don’t get along with the substances used for sealing and coating. Using this guide will help you to identify the right sprayer for your job.