If you want to build a sprayer you need a pump. A pump’s job is simple but how you install a pump is critical. Improper plumbing can be a huge detriment to your sprayer pump’s performance and even lead to premature failure. Not to mention poor overall sprayer function. So how do you hook up your sprayer pump correctly?

In general, a sprayer pump should be installed using a reinforced suction hose that is at least as large as the pump inlet. There should also be a strainer in the suction line and a pressure relief valve in the discharge line.

The specifics of installing a sprayer pump can vary depending on the type of pump and sprayer as well as other factors. There are several pump types, in the rest of this post we will cover how to hook them up.

How to Hook Up a 12-volt Diaphragm Pump

12-volt diaphragm pumps can be used in many applications. They are great for small sprayers because they are relatively low cost, small, and they can run off the battery on an ATV, mower, pickup, etc.

Because they are self-priming And they can be run dry, they have a lot of versatility when it comes to where they can be installed. They can be mounted on top of a small sprayer and draw liquid up out of the tank with no problem.

While there are many ways to install a 12 V sprayer pump, There are some best practices to follow:

- Don’t use too small of a hose. Houses with a very small inner diameter can limit your flow

- Use heavy enough wiring and a fuse and the wiring harness

- Use a screen or strainer on the inlet of the pump or suction hose

- A pressure regulating valve should be installed on the discharge side of the pump. This will allow you to regulate the pressure

- If your 12 V pump is a demand-style pump, a pressure-regulating valve will be necessary to keep it from cycling on and off

If you’re not sure if you have a demand pump or like to see more details on how to install a pressure-regulating valve then definitely read through this post about using a regulating valve with your sprayer.

How to Hook Up a Roller Pump

Roller pumps have More requirements to follow in order to do it correctly. There are different orientations, shaft rotations, and operating RPM.

Shaft Rotation

Roller pumps are designed to be driven by a PTO on a tractor or a gas engine. Gas engines rotate in a counterclockwise direction and a PTO generally rotates clockwise. When hooking up a roller pump it is vital that you have the correct model and that you install it so that the shaft will be turning in the correct direction.

In addition to the direction of the shaft rotation, the rpm is an important factor. Gas engines are typically about 3500 rpm, while a PTO can be 540 or 1000 rpm. Roller pumps will have a max rpm that they can operate at, so you must consider this when mating them to your tractor or engine.

The roller pumps with clockwise shaft rotation (Hypro models with R) will mate to gas engines, and roller pumps with counterclockwise shafts will mate to a PTO.

This chart shows the most common roller pump models, their shaft direction, max RPM, and the recommended suction hose size to use. Remember clockwise rotation will mate to a gas engine and counterclockwise to a PTO.

| Roller Pump Model | Max RPM | Shaft Size (inches) | Shaft Rotation (When looking at the shaft) | Suction Hose Size (inside diameter) |

|---|---|---|---|---|

| Hypro 4001 | 1800 | ⅝ | Clockwise | ¾ inch |

| Hypro 4101 | 2600 | ⅝ | Clockwise | 1 inch |

| Hypro 6500 | 1200 | ⅝ | Counter CW | 1 inch |

| Hypro 6500 R | 1200 | ⅝ | Clockwise | 1 inch |

| Hypro 7560 | 1000 | 15/16 | Counter CW | 1 inch |

| Hyrpro 7560 R | 1000 | 15/16 | Clockwise | 1 inch |

| Hypro 1700 | 1000 | 15/16 | Counter CW | 1-¼ inch |

| Hypro 1700 R | 1000 | 15/16 | Clockwise | 1-¼ inch |

| Hypro 1500 | 1000 | 15/16 | Counter CW | 2 inch |

| Hypro 1500 R | 1000 | 15/16 | Clockwise | 2 inch |

| Delavan 4900 | 2600 | ⅝ | Clockwise | 1 inch |

| Delavan 6900 | 1200 | ⅝ | Clockwise | 1 inch |

| Delavan 6900 R | 1200 | ⅝ | Counter CW | 1 inch |

| Delavan 7900 | 850 | 15/16 | Clockwise | 1-¼ inch |

| Delavan 8900 | 1000 | 15/16 | Clockwise | 1-¼ inch |

| Delavan 8900 R | 1000 | 15/16 | Counter CW | 1-¼ inch |

| Ace RP600 | 1200 | ⅝ | Clockwise | 1 inch |

| Ace RP600 R | 1200 | 5/8 | Counter CW | 1 inch |

| Ace RP800 | 1000 | 15/16 | Clockwise | 1 inch |

| Ace RP800 R | 1000 | 15/16 | Counter CW | 1 inch |

Suction Hose

The suction hose, the hose used to supply the pump, needs to be a reinforced hose that does not collapse under suction. A standard rubber hose will not work. At a minimum, the inside diameter of your suction hose should be at least the same size as the inlet on the roller pump. If the pump is going to be operated at higher rpm or the suction hose is going to be longer than 5 feet then you should definitely use a hose with a larger inside diameter than your pump inlet port.

A roller pump should not be expected to lift water more than a few feet, so it is also important to install the pump at a level below or as close to the bottom of your sprayer tank as possible.

For example, a Hypro model 6500 roller pump has ¾ inch national pipe thread ports. A one-inch inside diameter hose is ideal when hooking up the pump to ensure there is enough liquid supplied to keep up with the pump.

Shaft/PTO Couplers

Another important aspect of hooking up a roller pump is the PTO or engine coupler. Roller pumps generally have a solid keyed shaft. For a gas engine, you will need two couplers that fit together, one with a bore size matching the engine shaft, and one that fits the pump shaft.

These types of couplers are commonly used to connect a Hypro 6500R to a Honda GX160 gas engine.

To connect a roller pump to a PTO, you will need a splined shaft coupler. Hypro quick coupler 1323-0077 will adapt a roller pump with a ⅝ inch shaft to both a 540/1000 rpm PTO. Hypro coupler 1323-0076 will connect a roller pump with a 15/16 inch shaft to both 540/1000 rpm PTO.

Roller Pump Mounting Brackets

A roller pump requires a mounting bracket in order to operate properly. If it is installed on a PTO then you’ll need a special torque bar connected to a chain. This keeps the pump in place as a PTO spins.

When driven by a gas engine you will need to mount the pump on something so that the shafts are aligned.

Regulating Valve & Strainer

Roller pumps are in the positive displacement pump family, so they require a pressure relief/regulating valve on the discharge side. This is done simply by incorporating a “Tee” fitting directly in the outlet of the pump so you have an extra port for the regulating valve. The bypass port on the regulating valve can be directed back to the tank.

A strainer should also be used on the suction side/inlet of the pump. Any solid particles or debris can harm the rollers in the pump. A strainer will help to prevent this, however, make sure your strainer is adequately sized so it does not restrict the pump. It is a good idea to use a strainer with port sizes the same or larger than the suction hose.

If you would like a more complete plumbing guide for a roller pump, then view this post on sprayer plumbing, for more detailed diagrams.

How to Hook Up a Diaphragm Pump

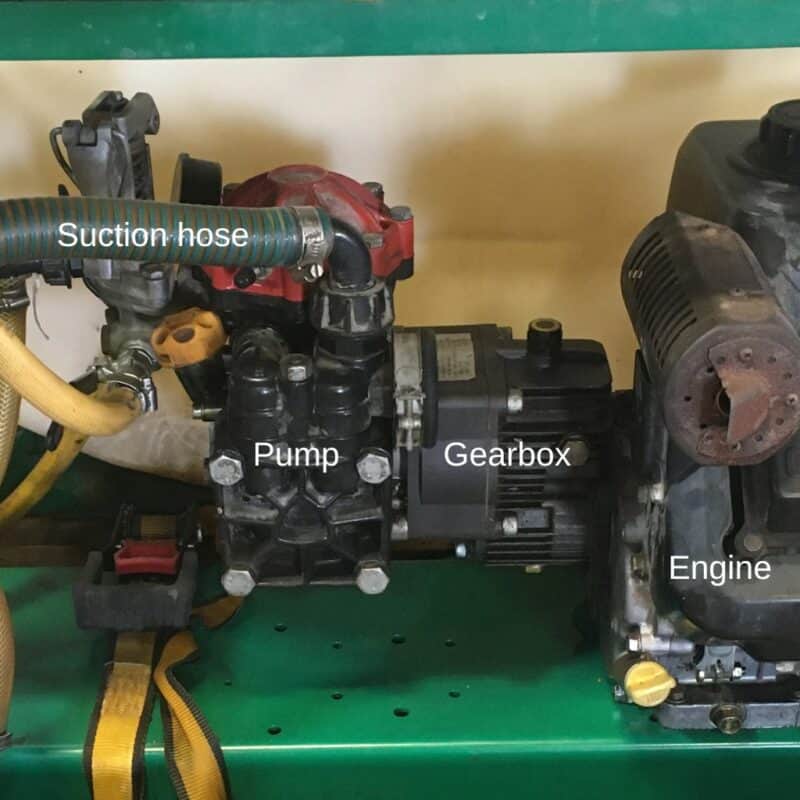

A diaphragm pump is commonly used for turf care, tree spraying, soft wash, and more. They can be driven by almost any power source that has enough horsepower and delivers adequate rpm.

When Hooking up a diaphragm pump it is critical to connect everything correctly. Fortunately, the pump manufacturers know this and have designed the pumps in a way that makes things fairly simple.

Using a gas engine to drive this type of pump is very common so many models come with a gearbox that allows the pump to be installed directly onto the engine.

Pressure Control Unit

Diaphragm pumps are made to develop high pressure, some will produce over 700 psi. This requires a pressure-regulating valve. Most manufacturers will sell their diaphragm pumps with a pressure control unit installed so all you have to do is mount the pump on your engine/motor and connect the hoses.

Hoses & Strainer.

A diaphragm is no different than other pumps, you need to make sure to use reinforced suction hose from the tank to the pump inlet. Often, the pump will come with an inlet barb already installed. You will need a suction hose that fits this and should not change it to a smaller size.

A diaphragm pump can lift water out of a tank but you should not expect a diaphragm pump to lift water more than about 8-9 feet. Whenever possible, install the pump as close to the tank outlet as possible.

A strainer on the suction side is required to keep debris from the pump. This strainer should have inlet/outlet ports at least as large as your suction hose.

Hose connections on the suction side should be airtight. Clamps need to be tightly in place. If there is any spot where air can get into the suction plumbing then the pump can fail to prime. If you are looking to set up a complete tree sprayer or skid unit, I wrote an article that covers the details of all you need for a tree sprayer using a diaphragm pump.

How to Hook Up a Centrifugal Sprayer Pump

All the rest of the pumps we discussed in this article are positive displacement pumps. Centrifugal pumps are in a class of their own. They have different characteristics that need to be considered when hooking them up on a sprayer.

The main difference when installing a centrifugal pump is that they do not require a pressure relief valve. If the discharge is blocked or valves on the discharge side are closed, the pump will only build pressure to a certain amount. However, you would not want to run a centrifugal pump like this for very long, liquid can get hot and damage the pump. The best practice is to have a bypass line installed on the discharge line anyway. This will help provide pressure regulation and avoid liquid getting too hot if the discharge is blocked.

Centrifugal Sprayer Pump Location

When you install a centrifugal pump on a sprayer it is important to make sure that the pump inlet will be “flooded”. In other words, liquid from the sprayer tank will gravity flow from the tank outlet to the pump. A centrifugal will be damaged if it is run dry so making sure the pump is adequately supplied with liquid is vital.

Suction Hose

A reinforced suction hose with an inside diameter equal to or larger than the pump inlet is required. A centrifugal pump creates a lot of suction and it will collapse a standard rubber hose, starving the pump and causing pump failure.

The hose and hose connections need to be solid and secure to avoid air getting into the suction line. Air inside the pump can lead to cavitation and pump failure.

Suction Strainer

It is always a good idea to have a strainer in the suction line. A “Y” strainer with a 20-30 mesh screen works great for centrifugal pumps. Just like the suction hose, the strainer needs to allow adequate flow to the pump. For a pump with a 1-inch inlet make sure to use at least a 1-inch strainer, 2-inch inch for a 2-inch pump, and so on.

Priming a Sprayer Pump

There are two different types of centrifugal pumps. Straight and self-priming. A self-priming pump can “lift” liquid from below its inlet. This means a self-priming pump doesn’t require flooded suction like a straight centrifugal pump would.

However, you still need to prime the pump when initially hooking it up. This means filling the pump with liquid before operating it. Even though the pump will lift liquid into them, there needs to be fluid inside the pump to protect the seal.

When possible it is still advised to install a self-priming pump as close to the outlet of the tank as possible. For more information about centrifugal pumps refer to this guide.

More Information on Sprayer Pumps

There are several different types of pumps used on sprayers. The differences can be subtle, and identifying the right one for your needs can be difficult. We have put together a full guide on the different sprayer pumps, it will help you identify what type is right for you.