One of the most important parts of any sprayer is the regulating valve. They have a crucial role in sprayer plumbing; which provides the user the ability to control the operating pressure of the sprayer. If you are new to sprayers or want to build a DIY spray rig you likely have questions about how a regulating valve works, what type you need for your sprayer, and how to install it. So read on for some straightforward answers!

What is a Pressure Regulating Valve

A pressure-regulating valve is a type of valve used to regulate and maintain consistent pressure in a sprayer. The valve is typically installed off the main discharge line of the system and helps to control the flow rate and pressure of the liquid being sprayed.

The ability to accurately control pressure is important to ensure that the spray pattern and droplet size are consistent and uniform, which is necessary for achieving effective and efficient coverage of your target area.

Pressure regulation can be achieved with manual or automatic valves depending on the specific application and system requirements. Manual valves are most common on small sprayers. Manual valves are typically adjusted by hand to achieve the desired pressure level, while automatic regulating requires an electronic valve and pressure sensor or other devices to monitor and regulate the pressure level automatically.

How Does a Pressure Regulator Work on a Sprayer?

When liquid flows through the valve, a spring-loaded piston or diaphragm inside the valve opens when the set pressure is reached. The spring forces it shut when the system pressure is below the valve setting.

The pressure it takes to open the valve can be adjusted by the user. Typically this is done by turning a knob or dial by hand. The valve will typically have a port for a pressure gauge. This allows the operator to see the pressure level and adjust the dial to reach the desired pressure setting. The valve is designed to maintain a consistent pressure level in the sprayer, regardless of changes in the flow rate.

There are different types of pressure-regulating valves. They come in different sizes, materials, and pressure settings. There are also differences in the method they use to open and close. There are piston styles, diaphragm, and others. Essentially, they all function the same.

A pressure regulating valve also acts as a relief valve or “bypass valve”, sending excess flow back to the supply tank, thus limiting the maximum pressure that can be reached in the system. Pressure relief/regulating valves can be easily confused with other types of valves like throttling valves. A throttling valve is slightly different in that it regulates flow and not pressure. It is normally installed on the main discharge line of a centrifugal pump and regulates the flow to a sprayer accessory such as an agitation line.

Related: Sprayer Parts & Their Function

Do You Really Need a Pressure Relief/Regulating Valve?

While a pressure regulating valve is not always required in every sprayer, it can be very useful for achieving consistent and effective application of liquids. If you are using a 12-volt demand pump, the type often used on ATVs, UTVs, and lawn sprayers, a regulating valve will keep your pump from cycling on and off. For full details on this, you can read this post about why 12-volt spot sprayers surge or pulse.

If your sprayer pump is a positive displacement pump, you will definitely want a pressure-regulating valve. Roller pumps, diaphragm pumps, and piston pumps are all positive displacement pumps. This type of pump will build pressure when restricted and if there is no outlet then pressure can build to a level that will damage the sprayer. A regulating valve can act as a relief valve, allowing excess flow back to the sprayer tank when the spray gun or boom valve is closed.

Here are some other reasons why you might want a pressure-regulating valve:

- Consistency: A pressure regulating valve can help maintain a consistent pressure level in the spraying system, which is important for achieving consistent and even application of your spray solution.

- Safety: Over-pressurization of the spraying system can result in broken parts or leaky fittings. Not to mention the potential harm to the operator.

- Calibration: When calibrating a sprayer, it is important to ensure that the correct pressure is being used each time you spray to achieve to maintain your target application rate.

Ultimately, the specific requirements of your spraying system will determine whether or not a pressure-regulating valve is needed. However, It is strongly recommended that you use a regulating valve on just about any sprayer. Without one, you must rely solely on the restriction from the spray nozzle(s) on your sprayer and the output of your pump. This means if you need to change the pressure you must change nozzles or increase/decrease your pump output, which can be more complicated.

You can use a regular ball valve or gate valve to make adjustments to the pressure of the sprayer but although this is possible it is not very precise. With a regulating valve, you can dial in a precise operating pressure making your sprayer much more efficient and accurate.

Related: Electric Sprayer Controls

How to Add a Pressure-Regulating Valve

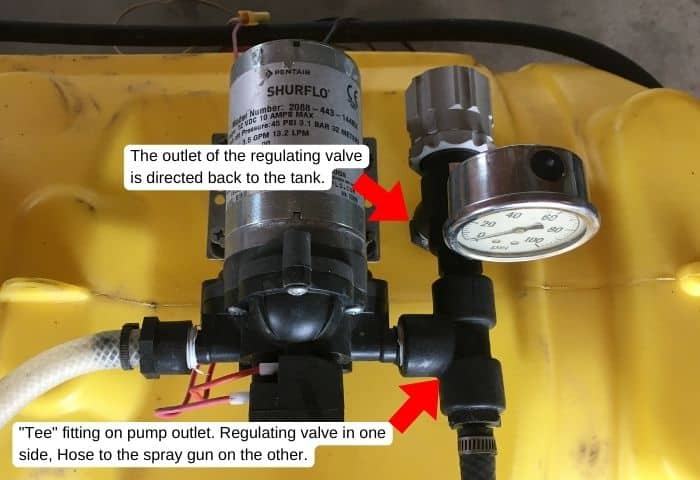

Adding a regulating valve to an existing sprayer or a sprayer you are building may seem complicated but it is actually pretty straightforward. The specifics will vary slightly based on the type of sprayer you have and the size of the valve you use. In general, you will want to add a “tee” fitting Into the outlet of the pump. This will allow flow from the pump to continue to the boom or spray one that’s normal but also give you a port to put the regulator valve.

The regulating valve will typically have a male-threaded inlet and a female-threaded outlet. The inlet will be at the “bottom” with the outlet on the side and the adjustment knob on the top. You install the male pipe thread into the branch side of your “tee” fitting. You will connect the hose to the outlet of the valve and then that hose runs back to a port on your tank. You may have to add bulkhead fitting into your tank so you have a place to connect your return line from the regulating valve. A bulkhead fitting can be added easily, all you need is a drill and the appropriate size hole saw bit.

You might wonder if you can use the bypass line from your regulating valve as an agitation line. While the bypass line will result in some agitation, it’s important to know that you’re agitation line and a bypass line should be separate. Adding an agitation jet or nozzle can restrict flow and potentially get plugged, if you were using the agitation line as your pressure relief or bypass line, this could create problems. You can see more information in this article about adding an agitation feature to your sprayer.

The image below shows a simple pressure regulating valve installed on an ATV spot sprayer.

When adding a pressure regulating valve to an existing sprayer you might have some space limitations or pre-existing plumbing to work around. This leads to the question: can you install a regulating valve upside down or horizontally? For most valves, the answer is yes. The piston and/or diaphragm are not affected if upside down and will still open at the desired setting.

If you are trying to set up a full sprayer, you can read this post that provides several sprayer plumbing diagrams.

What Type of Regulating Valve Should I Use on My Sprayer?

As mentioned earlier there are different types of regulating vowels. The type you use will vary depending on your sprayer but here are a few things to consider.

- Maximum pressure of your sprayer. If your sprayer pump is capable of producing 300 psi, then you need a pressure regulating valve rated to that pressure. Even if you intend to spray at lower psi levels.

- Chemical compatibility. If you spray pesticides or other agrochemicals, you will need a valve that is compatible. Likewise, if you are using a sprayer for cleaning products, sealers, de-icers, etc. Poly and nylon are great for herbicides and de-icer. Brass or iron may be best for petroleum products. There’s usually a lot of overlap in compatibility with different materials and sometimes specific products might be harder on materials than others.

Although there are several different types of regulating valves available, the one I recommend for DIY lawn sprayers, UTV sprayers, and small boom sprayers is the Teejet manual regulating valve. This valve is versatile and perfect for all types of sprayers.

What PSI Should I Set a Pressure Relief Valve?

In simple pressure control systems, this would be the majority of lawn turf, ATV, or spot sprayers where you are controlling the sprayer output with just a regulating valve. In this scenario, Your regulating valve should be set at the pressure you desire to spray. If you are unsure how to determine the correct operating pressure in your situation you can read this article about determining what pressure to spray.