I have used many different types of sprayers in my life and it seems, no matter what type of sprayer you use eventually they stop working. In my younger years, I would get frustrated, move on to a different sprayer, and continue what I was doing. But as I got older and more curious about how things work. I started to wonder what causes a sprayer to stop working.

Sprayers stop working for many reasons. The primary reason the sprayer stops working is due to damaged or dirty parts of the pump or pump assembly. This can occur as a result of normal wear and tear or chemical residue. Of course, the specific reason why a sprayer stops working can vary depending on the type of sprayer.

There are several factors at play and a thorough explanation requires a closer look at different sprayers. So let’s examine several different sprayer types of the main reasons why they sometimes fail.

Common Reasons Why Sprayers Stop Working

First Let’s look at the general reasons for sprayer failure then we can dig into specific sprayer types and guide you to the solutions. Here are several common reasons why sprayers fail:

- Clogging: Nozzles, filters, or hoses can get clogged with debris or sediment from chemicals and water.

- Wear and Tear: Over time, parts of the sprayer, such as seals, hoses, and nozzles, can wear out or degrade, especially with frequent use or exposure to harsh chemicals.

- Improper Maintenance: Failure to properly clean and maintain the sprayer after each use can lead to residue build-up, corrosion, and eventual failure of components.

- Pump Issues: The pump is a critical component of any sprayer. Issues such as loss of pressure, leaks, or failure to prime can occur due to wear, damage, or air leaks in the system.

- Leaks: Leaks can develop in various parts of the sprayer, including the tank, hoses, fittings, and connections, often due to loose connections, cracked hoses, or failing seals.

- Electrical Problems: For electric sprayers, electrical issues such as dead batteries, faulty wiring, or damaged switches.

- Chemical Incompatibility: Using chemicals not compatible with the sprayer’s materials can cause parts to degrade or fail prematurely.

- Pressure Regulation Issues: Problems with the pressure regulator can lead to inconsistent spray patterns or inadequate coverage.

- Improper Assembly or Use: Incorrect assembly or using the sprayer for applications it wasn’t designed for can lead to failure.

- Storage Issues: Improper storage, especially in extreme temperatures or without proper cleaning and draining, can lead to damaged components and reduced lifespan.

When lawn sprayers stop working, the reasons can vary widely depending on the type of sprayer you’re dealing with. Here’s a breakdown of possible issues for different types of sprayers, including hand pump sprayers, backpack sprayers, small pull-behind boom sprayers, and commercial skid sprayers or spray rigs:

Why Hand Pump & Backpack Sprayers Fail

Clogged Nozzles

Small particles or dried chemical residue can block the nozzle, preventing the sprayer from working properly. Even a small amount can harm your sprayer’s performance. The result is uneven spray patterns and inconsistent application of your pesticide.

I find the best way to avoid this is rinsing your sprayer with fresh water after each use. At the end of a season, or before storing your sprayer for an extended period, use a tank cleaner to wash out the entire sprayer. This will mitigate and remove as much chemical residue as possible.

Leaky Seals or Gaskets

Over time, seals and gaskets can wear out or get damaged, leading to loss of pressure and the inability to spray. This is a common issue with hand-pump garden sprayers.

The seal around the plunger in the pump assembly can lose its shape and resilience over time. A simple solution is to apply some silicone grease or petroleum jelly. Usually, there’s an O-ring that seals around the plunger as it travels up and down inside the piston. Lubricating this o-ring will often help the o-ring to seal up properly again. You can see more information in this post about troubleshooting and repairing garden sprayers.

Pump Failure

The manual pump mechanism can fail due to normal wear or damage. This makes it impossible for the sprayer to build pressure.

Manual hand pump sprayers are typically very similar. If the pump assembly, whether piston or other, is not sealed properly, it won’t work. A crack in the piston housing, a bad o-ring, or a worn-out check valve in the bottom of the pump assembly can all cause the pump to fail.

Fixing these issues often requires repair parts. Many lawn and garden sprayer manufacturers offer repair kits, but some do not. Unfortunately, inexpensive sprayers are typically not very economical to fix, and you will need to replace the entire sprayer.

I have been able to find replacement parts for my Solo hand and backpack sprayers. There are also parts available for Chapin sprayers and others.

Improper Assembly

Incorrect assembly after cleaning or maintenance can lead to leaks or loss of pressure. If you disassemble a sprayer for repair, keep all the pieces organized so that you can replace them in the proper order.

Housing/Tank Cracks

A crack in a sprayer tank is probably the most frustrating sprayer issues. It is hard to fix and ultimately means you will probably need a new sprayer. I have a Solo hand sprayer with a small crack in the tank and it is very frustrating because everything else works fine but it does not function. The crack means that I cannot build up enough pressure to spray effectively.

Bad Vent/Relief Valve

Many of the hand-pump lawn and garden sprayers have a vent or relief valve. This allows you to release the pressure in the sprayer when you are done spraying. It’s a convenient feature but it is another place for air to escape.

If this valve is not sealing up properly, then you won’t be able to build any pressure. Making your sprayer pretty useless. To fix this issue, clean around the o-ring and lubricate with Vaseline. If this does not work, then check if your sprayer brand sells a replacement vent/relief valve kit.

Why Boom Sprayers Fail

Leaking Pump Seal

Large boom sprayers utilize centrifugal pumps. These are high-volume pumps that have a very simple design. The key component of a centrifgual pump is the shaft seal. The drive shaft from the motor turns the impeller in the pump. There is a mechancial seal around this shaft that keeps the pump from leaking.

Friction, heat, corrosion, and a pump running dry, can cause this seal to fail. A serious fauilure will create a mess and severely limit your sprayers function.

Wear and Tear

Over time, the internal components of the pump, like seals, valves, and diaphragms (in diaphragm pumps), can wear out. This wear can lead to decreased pump efficiency, leaks, and eventually, complete failure if not addressed.

Lack of proper maintenance, such as not cleaning the pump thoroughly after use or failing to lubricate moving parts, can lead to pump failure. Regular maintenance is crucial to ensure the longevity and proper functioning of the pump.

The best practice is to thoroughly understand the maintenance guidelines of your specific pump and follow them accordingly.

Corrosion and Chemical Damage

Sprayer pumps are often exposed to chemicals that can be corrosive or abrasive. Over time, these substances can damage the pump’s components, especially if the pump materials are not compatible with the chemicals being sprayed.

I talk about compatability in this post on different sprayer seal materials.

Foreign Objects and Debris

Debris or foreign objects entering the pump can cause physical damage to the internal components. This issue underscores the importance of strainers and filters in protecting the pump.

You can see a complete guide in this aricle on sprayer strainers.

Electrical Issues

Smaller boom sprayers for lawn and turf typically use a 12-volt pump. Problems with the electrical supply, motor, or connections can cause electric pump failure. This includes issues like blown fuses, overheating, or bad connections.

Clogged Filters

A filter’s job is to remove debris and sediment from the system and protect the pump and other sprayer components. Over time, the strainer bowl can fill up and this causes problems. If the strainer is on the suction (inlet) side of the pump, it can keep the pump from priming.

Nozzle Problems

Nozzles will suffer wear over time. They can also get partially or completely clogged. When wear occurs in the spray tip, the nozzle pattern and volume will change. This happens slowly over time and it can be hard to notice.

If the sprayer is producing inconsistent results, then be sure to test all the nozzles. This is the only way to ensure they are all producing the same volume of spray and delivering an even spray. If you find a nozzle(s) is producing a higher volume than the others, it should be replaced. No nozzle should be producing a volume more than 5% higher or lower than the average of all the spray nozzles on your boom.

If you notice a change in the spray pattern, then clean the nozzles. Even if they do not appear plugged, even slight chemical residue can affect the pattern.

Regulating Valve Failure

Manual regulating valves consist of a spring and piston or diaphragm inside. These are wearable pieces that can wear out. If your sprayer is no longer building pressure as normal, the regulating valve may be opening at a lower pressure. This means that you aren’t able to accurately control your pressure.

An electronic regulating valve can also cause sprayer issues. A valve can get “stuck” and not turn freely due to chemical corrosion or residue. The electronic motors can also fail if the correct voltage is not supplied.

Commercial Skid Sprayers and Tree Spray Rigs

Pump Needs Maintenance

The type of pumps used on commercial turf and tree spray rigs are typically medium and high-pressure diaphragm pumps. These pumps require oil and diaphragm changes periodically. The diaphragms are wearable moving components. When they wear, they can let oil leak into the fertilizer or fluid you are spraying. This can affect your results, damage plants, and lead to permanent pump damage.

Generally, the manufacturer will want you to change the diaphragms every three months or 500 hours of use. The crankcase oil should be changed each time the diaphragms are changed. If you are working with a diaphragm pump for the first time, then definitely read this guide to troubleshooting a diaphragm pump.

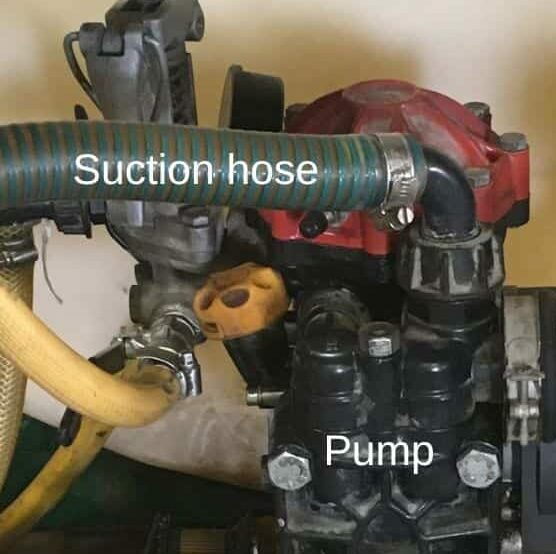

Plumbing Problems

When a spray rig fails, one of the common culprits is failure to prime. This is often due to an issue in the suction plumbing. This can be cracks in the hose, leaks in fittings, plugged strainers, etc. Anything that lets air into the system can prevent the pump from priming.

You can see a detailed explanation in this guide on how to correctly hook up a sprayer pump.

Pressure Regulator Failure

A pressure-regulating valve is essential for controlling the operating pressure of your system and directing flow to different outlets. It is also an important safety mechanism that will relieve pressure when the spray gun is closed.

You should never operate a piston pump or diaphragm Pump without having a pressure regulating valve installed, either directly on the pump or in the discharge line. Also, it’s a good idea to start the pump with the pressure regulating valve set to full by-pass.

A worn-out regulator can cause serious problems like burst hoses. It is also crucial to install the regulator correctly to avoid a catastrophic failure. Inspecting the regulating valve often and adhering to proper seasonal maintenance is key.

Conclusion

For all types of sprayers, routine maintenance is key to preventing many of these issues. Regular cleaning, inspection, and replacement of worn or damaged parts can extend the life of the sprayer and ensure it operates effectively. Always refer to the manufacturer’s guidelines for specific maintenance recommendations and troubleshooting steps for your particular model.