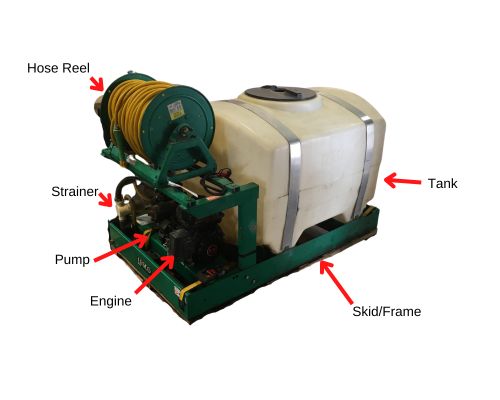

Many people have different definitions and terms that they use to describe different types of sprayers. Generally, the term Spray Rig usually refers to a somewhat customized sprayer that is mounted on a truck or trailer and used for lawns, turf, trees, and much more.

You might call it a spray rig, skid sprayer, tank sprayer, etc. No matter what you call it, spray rigs are typically pretty straightforward sprayers that don’t have a lot of extra bells and whistles. So they can be constructed by almost anyone and customized to fit your needs.

If you are considering building a spray rig and are looking for a detailed list of the components and a plumbing diagram you found the right place. Let’s break down the different components needed to put it all together.

Understanding the Components of a Spray Rig/Skid Sprayer: A Detailed Guide

Spray rigs can be used to apply fertilizer on lawns, spray pesticide in tall trees, and even be used for cleaning applications. Depending on what your needs are the specific components can vary but the general pieces needed to stay pretty consistent.

Here is a list of the basic spray rig and skid sprayer components:

- Tank

- Skid

- Pump

- Engine

- Regulating Valve/Control Unit

- Hose Reel

- Hose

- Spray Gun

- Spray Nozzle

- Filter

- Tank Valve

Now let’s go into a little more detail about each component.

The Tank

Description: The tank is the primary storage for the liquid (water, herbicide, pesticide, etc.) to be sprayed. Spray rigs for pest control are commonly between 50 and 200 gallons in capacity however some industries utilize larger tanks such as tree and crop sprayers.

Polyethylene tanks are the most common. fiberglass, and stainless steel, can also be used but are typically more expensive. Polyethylene is compatible with a very wide range of chemicals.

The tank design is not critical, but you should consider the center of gravity when putting the tank in the back of a truck or a trailer. It is also worth considering where the outlet of the tank is located. Many tanks have an outlet on the bottom of a tank wall, but there are tanks with sumps in the bottom for a complete drain.

The Skid

The sturdy frame Serves as the base for all components of the sprayer to be mounted on. In some cases, the base may be part of the truck, trailer, or vehicle that the spray rig is mounted on. But Spray and Regular, are limited on a skid that makes it easy to move in and out of truck beds or onto trailers.

If you have a tank with a sump in the bottom, make sure the skid elevates the tank enough to accommodate the outlet fitting and valve underneath the tank.

The Pump

The heart of the sprayer, the pump is responsible for moving the liquid. The type and size of the pump will affect the sprayer’s overall ability to pressurize the liquid.

There are several different types of pumps back in to use on the spray rig. Each different type of pump will have Dozens if not hundreds of variations. Different types are made to provide slightly different performances different on the gallon-per-minute flow rate they can produce and the pressure range.

Centrifugal pumps, roller pumps, diaphragm pumps, and piston pumps can all be used depending on your needs. You can examine the specific details of all these different types of pumps in this guide that explains the various types of sprayer pumps.

A diaphragm pump is by far the most common type of pump that is used on a spray rig for long care and tree care applications. These pumps are uniquely designed to produce a combination of flow rate pressure to launch liquid great distance. They can also handle a wide variety of different fertilizers and herbicides.

If you would like more details on diaphragm pumps be sure to check out this article that explains diaphragm pumps

The Engine/Drive

A spray rig pump is typically driven by a gas engine but other drive types can be used such as hydraulic motors or PTO.

The diaphragm pumps that are manufactured to be used on spray rigs and skid sprayers are often made to bolt directly onto a small gas engine. They include a gearbox so the pump is operated at the correct speed.

It is crucial to use an engine or drive that has adequate horsepower to drive your pump. Generally speaking, the higher the flow or pressure a pump is capable of producing, the more horsepower is required.

The Regulating Valve/Control Unit

Pressure control and regulating valves are crucial components in skid sprayers, especially those using diaphragm pumps. They allow the operator to adjust the operating press and direct flow to the spray gun, agitation, or other accessories.

These valves also act as relief or bypass valves, returning excess flow to the supply tank and limiting maximum system pressure. In systems with positive displacement pumps like diaphragm pumps, a pressure-regulating valve is particularly important. Without it, pressure could build up to damaging levels when the flow is restricted, such as when the spray gun or boom valve is closed.

Want more information on regulating valves? Check out this guide that explains the ins and outs of sprayer regulating valves.

The Hose

The hose on a sprayer rig might seem pretty straightforward, but using the wrong hose can result in some serious issues. Essentially, two types of hose are needed a suction hose and a discharge hose.

The hose used on a spray rig needs to be rated to handle the maximum pressure your sprayer pump can produce. The hose should also be large enough to accommodate the flow required for your job. Hose size is typically measured by the inside diameter of the hose.

If you use a hose with a small inside diameter, you may restrict the flow of the pump and your sprayer will not perform as desired. For more specific information on sizing hose for different applications, refer to the hose section in this article about building a sprayer.

Hose Reel

The hose reel is an aspect of the spray rig that is not necessarily essential but it makes handling the hose easier. It also protects the hose and will help avoid unnecessary wear and tear to the hose cover.

There are manual rewind hose reels but you can also get auto rewind options. Some reels can automatically roll up the hose, they may be spring rewind, electric, air, and hydraulically driven.

Spray Gun

The spray gun is a component of a spray rig that the user will handle the most. There are several different types, made for various types of spraying. You should take careful consideration into the selection of the type you use.

The type of spraying that you need to do will drive your decision process. You won’t use the same type of spray gun to control weeds on a lawn and to spray tall trees. There is quite a bit of nuance involved in this decision. Fortunately for you, I have another guide that will give you a lot of information about the different types of guns used on spray rigs.

The Spray Nozzle/Tip

The spray nozzles you use can make a world of difference in achieving optimal results. Nozzles come in all sorts of sizes and designs. The nozzle impacts the rate you apply, the droplet size, the pattern produced, etc.

There are flat fan nozzles, solid stream nozzles, high-flow nozzles, and many other types. These are all intended for different applications. For example, a flat fan nozzle is typically used on a sprayer boom, while a stream nozzle is used for spot sprayers.

The topic of sprayer nozzles is too big to fully explain in this post, so if you want to learn more, take a look at these beginner’s resources:

- Different Sprayer Nozzle Types Explained

- What Do the Numbers On a Spray Nozzle Mean?

- Using a Sprayer Nozzle Chart

The Filter

A pump is a costly component of your spray rig. The filter protects the pump as well as the other components downstream from debris. Gravel, sand, leaves, and other items can easily get into the tank through the lid so a filter is definitely a component that will save you money and stress.

The main thing to understand about a filter is that they can have different screen sizes in them. The size refers to how small the openings in the screen are. This size is measured in openings per square inch. The higher the number the finer the mesh (smaller openings).

While a finer screen will block more debris, it can plug easier and be more restrictive on flow. Generally speaking, you want to choose the smallest screen you can that won’t restrict the liquid you spray and does not plug too often.

For more details, be sure to read this guide on strainers.

The Tank Valve

The tank valve is simply a valve that is installed in the outlet of the tank. While this valve will be open during operation, this is important to have. If you need to change the pump or work on it, you can close this valve and remove any of the components even if the tank has fluid in it.

In some cases, it may be convenient to install a three-way valve in the tank outlet. This will let you fill/drain the tank without needing to pump out the entire tank. Again, this gives you flexibility if you have a pump issue that needs to be addressed.

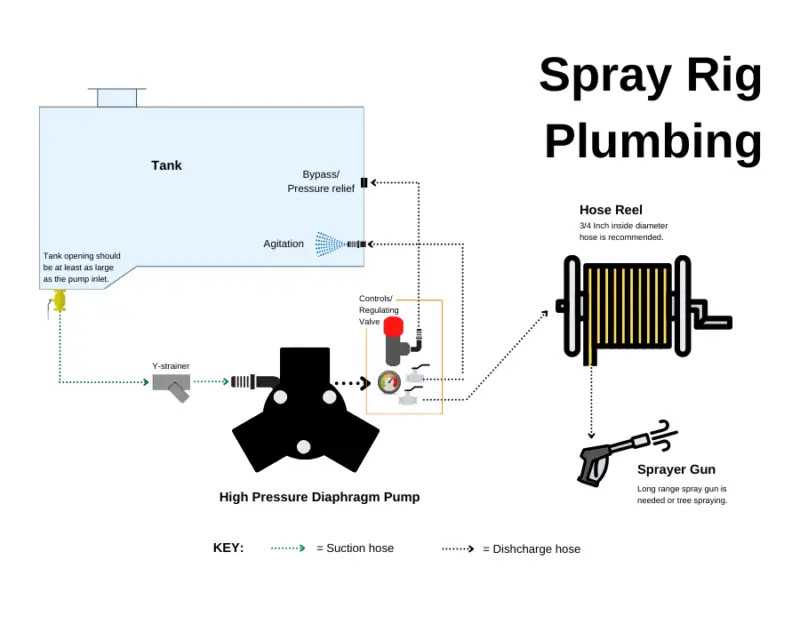

How Everything Fits Together

Spray rigs and skid sprayers are generally quite simple in terms of plumbing. Run hose from the tank to the pump, then from the pump to the hose reel and bypass. There are a few key things to keep in mind so that you ensure your spray rig will function properly and safely.

- Use a reinforced suction hose to feed the pump

- Ensure the suction hose is at least the same size as the pump inlet (inside diameter)

- Ensure that there is a bypass back to the tank from the regulating/control valve

- If using an agitation jet, be sure to set up a dedicated line separate from the bypass as it could plug.

There are different ways to plumb spray rigs but these are the basic guidelines. For more plumbing details refer to this guide on how to connect pumps in a sprayer.

Key Takeaways

In conclusion, understanding the various components of a spray rig or skid sprayer is crucial for anyone looking to build or customize their own. From the tank to the spray nozzle, each part plays a vital role in ensuring the efficiency and effectiveness of your sprayer. Whether you’re applying fertilizers and pesticides, or engaging in cleaning applications, the right combination of components can make a significant difference in your spraying tasks.

Remember, the key to a successful spray rig lies not just in selecting quality components, but also in how well they are integrated. The plumbing diagram and guidelines provided here are essential for setting up your spray rig correctly. Paying attention to details like hose size, pump type, and nozzle selection can greatly impact the performance of your sprayer.

Building a spray rig might seem daunting at first, but with the right information and a bit of effort, you can create a tool that is perfectly tailored to your needs. Whether you’re a professional in lawn care, pest control, or agriculture, or simply a DIY enthusiast, having a well-constructed spray rig can significantly enhance your efficiency and effectiveness.