A sprayer without controls can function but to get the most effective and efficient results you will need a control system for your sprayer.

Many sprayers come with a control method in place when you buy them. However, if you need something more sophisticated or want to build your own sprayer, it can be hard to identify the right one to use.

To help you, we will cover the various spray control options available for all types of sprayers. Whether you have a lawn sprayer, ATV sprayer, tree sprayer, or agricultural sprayer.

What is Sprayer Control?

Sprayer control can refer to the operation of several different components on a sprayer. Depending on the size and type of sprayer, there may be several different aspects to control. There is pressure, on/off boom valves, regulating valves, agitation, and more.

The two main aspects of sprayer control are rate control and then boom control. Rate control refers to the method the sprayer uses to regulate the output of the sprayer and section control is the method used to turn on/off your boom, spray gun, agitation, or other spray accessories.

There are several different methods to control your sprayer’s output. We typically measure the sprayer output in gallons per minute. A sprayer’s output is affected by the size of the spray nozzles on the sprayer and the operating pressure. Lower pressure means less flow over a period of time and higher pressure will mean higher output over that same amount of time.

The output is related to but not the same as the application rate. Application rate is determined by the size of the nozzles, pressure, as well as the speed you travel when spraying, and the width (inches) between each nozzle. For more a more detailed explanation visit this page that shows the different formulas used to calculate your sprayer output.

Let’s go over the basic types of sprayer control, with examples, then we will look at more specific sprayer control setups for different sprayer types.

Sprayer Rate Control Methods

A sprayer rate control system requires a means to monitor and control the liquid output of your sprayer. This is typically done by increasing or decreasing the flow generated by the sprayer pump. This can be done in a number of ways. Either by controlling the pump speed directly, or using a regulating valve. The regulating valve can be manually adjusted to bypass excess flow from the pump or a motorized electronic regulating valve can be controlled to open up and increase flow, or close down and limit the flow.

Manual Sprayer Control Options

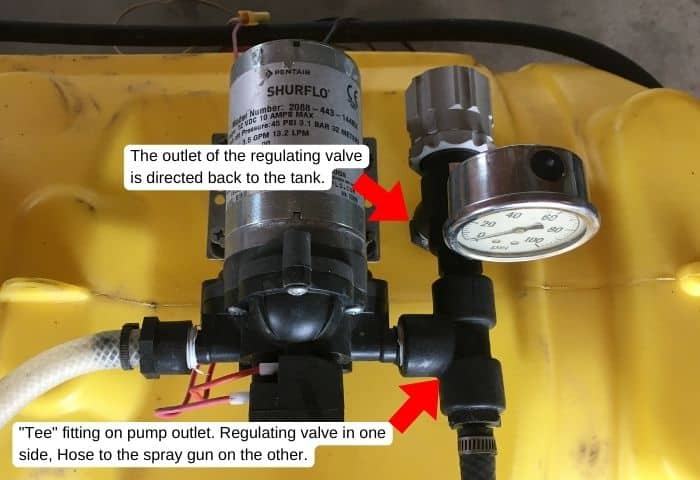

For simple sprayers, like lawn sprayers or ATV sprayers, the user monitors the pressure on a pressure gauge and adjusts a pressure regulating valve as needed. This is the simplest sprayer control method.

Components Needed for Simple ATV & Lawn Sprayer Control

- Regulating Valve

- Pressure Gauge

- “Tee” Fitting

If you have a sprayer and want to add a manual regulating valve, read my article that shows how to add a regulating valve to an ATV or lawn sprayer.

A full guide to building a DIY lawn sprayer with this type of control is available in this article about building a lawn sprayer

Electronic Sprayer Rate Control Options

There are more elaborate methods of manual sprayer control. These systems use an electronic regulating valve in combination with a pressure relief valve to control the flow of the sprayer. The user monitors the pressure with a basic pressure gauge, a pressure sensor that displays on a sprayer console, or a flow meter.

The adjustments to the flow are still done manually but with a toggle switch on a console that opens and closes the regulating valve. Texas Industrial Remcor offers several different “kits” that provide manual rate control and boom section control.

TIR Electronic Sprayer Control System

If you want to have an on/off valve for your sprayer boom or multiple valves to control boom sections, there are kits available to do this as well. You can do it with electronic solenoids, electronic ball valves, or manual on-off valves. We will look at some of these options later on in this article.

Automatic Sprayer Control Options

If you want the ability to set a desired application rate and have the system maintain that rate as you change speed, you need an automatic rate control system. These systems can operate based on pressure or a flow meter. Here are the components that are needed for both setups:

Pressure-Based Automatic Rate Control Components

- Rate control console

- Pressure sensor

- Speed sensor/GPS

- Regulating valve

- Electronic Harness/cables

Pressure-based rate control systems operate based on you guessed it, pressure. The control console monitors the operating pressure of the sprayer and the speed. When you program the console with your desired application rate, it will adjust the pressure as needed when you change speed. It does this by opening or closing the regulating valve. This all occurs simultaneously.

Flowmeter-Based Automatic Rate Control Components

- Rate control console

- Flow meter

- Speed sensor/GPS

- Regulating valve

- Electronic Harness/cables

Flowmeter-based rate control is similar in function, the console adjusts the regulating valve to increase or decrease the rate as speed changes. However, instead of monitoring the pressure and making adjustments this way, it monitors the actual flow rate of the liquid from the pump. This is achieved with a flowmeter. These systems can still use a pressure sensor or gauge to monitor the operating pressure, but this is not the factor that the console will use to adjust the sprayer output.

You can find a detailed explanation of The difference between pressure-based and flowmeter-based automatic rate control in this article on Electronic sprayer control.

The TeeJet 800 Series Sprayer Rate Controller will provide automatic rate control for both pressure and flowmeter setups. In addition to controlling the rate automatically, this console provides these benefits:

- Manual on/off control for up to five sections/valves

- Input your sprayer nozzle size by color

- An audible alarm notifies you if your rate is off

- Displays speed, PSI, target rate

Automatic Rate Control Sprayer Diagram

If you have a sprayer that lacks automatic controls you can upgrade the sprayer by adding the proper components. The plumbing and wiring can seem complicated at first, but the setup is pretty straight forward and it does not take long to get familiar with how all these components work together.

The diagram below shows one of many possible ways to plumb a sprayer for automatic rate control.

For a full sprayer plumbing diagram, see this post on ag sprayer plumbing.

Boom & Boom Section Control

Another desirable aspect of sprayer control is simply the ability to turn on and off your pump, boom, or boom sections remotely. This can be done manually or electronically. There are several different ways to achieve this depending on the type and size of your sprayer.

Manual Sprayer Boom Control Options

The most basic level of sprayer control is simply a valve in the hose or pipe that supplies your boom or spray gun. When you are not using one or the other, you can shut the valve off. Viola! Of course, this is not very user-friendly for pull-type sprayers or sprayers mounted on a mower, ATV, or small tractor. Most likely, you won’t be able to easily reach your valves while you are spraying, even if you can, it is inconvenient and potentially dangerous.

The more convenient option is remote controls for your sprayer boom. While the plumbing for electronic controls is simpler, manual controls are less expensive. However, it will require a bit more plumbing and hose to do so.

The most relevant application for remotely mounted manual sprayer valves would be on small pull-type lawn sprayers, or small ATV/UTV mounted or pulled sprayers. Like most sprayer setups there is more than one way to achieve this. Here are two manual sprayer control options:

Option #1: TeeJet Tee Valve

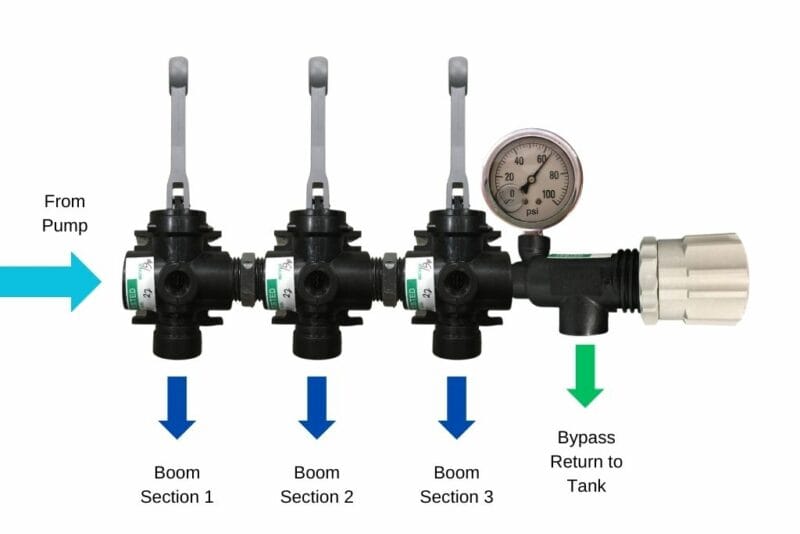

The “Tee” valve provides the operator with control over several different outlets. These could be a boom/boom section, spray gun, agitation, etc. The one-piece valve would be mounted somewhere the operator can easily access while spraying. The supply hose runs from the pump to the valve inlet. Hoses from each outlet to the necessary boom or section of the boom.

The valve settings are intended to correspond with up to three boom sections. You control what sections of your boom are on by turning the valve handle to the position that identifies with the boom section(s) you want to use.

Option #2: TeeJet Manual Directo Valve

The manual Directo valve controls a single boom section or sprayer gun, but multiple valves can be “stacked” together creating a manifold. The supply hose from the pump is plumbed into either of the side ports, the other can be used to install your regulating valve. These two side ports are interchangeable. The bottom port is the outlet that can be switched on and off. You connect the hose that supplies your boom or boom section to this port.

Electronic Sprayer Boom Control

The other option to turn your boom on and off is electronic valves. These valves allow you the same benefits as the manual on/off control valves and do not need to be located close to the user. They can be installed wherever is easiest in the plumbing and the switches that operate the valves are mounted where the user can reach them.

Instead of running hoses filled with liquid all the way to the manual valve, you simply run wires from the electronic valve to the switch. You can use solenoid valves or electronic ball valves. Solenoid valves are less expensive but ball valves are more reliable.

Whichever type of electronic valve you use, they can also be “stacked” together to create a manifold that allows you to direct flow to several boom sections or spray accessories.

Choosing a Sprayer Control Setup

Identifying the right sprayer control for your application can be challenging with so many options available. There are a few main things to consider:

- Type of spraying: Agriculture, professional turf management, de-ice, personal lawn, etc. There are many types of spraying tasks and their needs are different. For example, if you are a farmer or turf care pro then the more complex automatic rate control systems may be necessary to provide you with the accuracy and efficiency to be profitable. For personal or home use, a simpler basic method would be adequate.

- How will you spray: If you only need to spray a few acres a couple of times a year, then automatic rate control and electronic valves is probably overkill. If you spray hundreds or even thousands of acres of land, then a fully automated electronic spray control system with GPS guidance could help you save time and money.

- Budget: The bottom line is the cost! Manual controls or automatic can ultimately both get the job done. So if your budget only allows for pressure-based, manual spray control you can still be effective.

Also, while there are not necessarily any “standard” sprayer control systems, there are some that are more commonly used in specific applications.

Lawn & Garden Spray Control Setup

A sprayer that will be used on small lawns or gardens does not require much in terms of controls. Outside of a manual shutoff valve or two you will want a manual regulating valve to control pressure. The regulating valve can be mounted right by the pump and return the bypass line directly to the tank. For a complete plumbing diagram, check out this article on building a lawn sprayer.

Components needed for basic lawn sprayer controls:

- Regulating Valve

- “Tee” Fitting

- Pressure Gauge

- Bypass hose/plumbing

Pasture/Food Plot Sprayer Control Setup

If you maintain properties larger than your typical lawn or garden, you can benefit from more elaborate controls than a basic regulating valve. When you spray pastures, food plots, roadsides, etc., your speed will likely vary far more than on a small flat lawn. If your speed is changing then you need the ability to easily change your sprayer’s output as you spray.

Here are the basic components needed to control the sprayer output on a small boom or boomless sprayer used on pastures, food plots, etc:

- Control console

- Pressure sensor/Gauge

- Electronic regulating valve

- Relief valve

RELATED: ATV Sprayer Guide

De-Ice Sprayer Rate Control System

Applying any de-ice or anti-ice liquid over a public road will require the ability to adjust your rate and turn on/off your sprayer boom from the cab of the truck.

Driving in traffic obviously requires the operator to focus on the road. For safety reasons, it is recommended that you have an automatic rate controller so the driver doesn’t need to fiddle much with valves or controls while driving.

Additionally, the application rate of de-ice/anti-ice liquids on a road or highway is measured in gallons per lane mile instead of gallons per acre. Not all sprayer rate controllers can be programmed this way.

The RoadMaster Rate controller from Micro-Trak is designed for highway and road de-ice applications.

Final Thought

Basic sprayer controls will work in a variety of applications. More sophisticated sprayer control setups are designed to fit specific tasks and make operating the sprayer more convenient and efficient. Personal preference as well as the level of precision your application requires will ultimately determine what system meets your needs the best.