Spraying a small yard or garden can be easily handled by a hand pump sprayer. But If you have a new larger piece of property that won’t cut it. Whether for personal or commercial use the most effective way to evenly spray a large area is with a boom sprayer. You are likely somewhat familiar with boom sprayers however you may not know how many variations there are and what kind would work best for you.

The aim of this article is to help you identify if a boom sprayer makes sense for your application and how to select the right one.

What is A Boom Sprayer?

The definition of a boom sprayer is straightforward but broad. Essentially, it is any sprayer that uses a boom as its means of pesticide application. They are typically known for applying herbicide on crops, pastures, golf courses, and lawns, but they are used in many other applications such as dust control, and anti-ice.

There is virtually no limit to the different styles and variations of boom sprayers. From small simple sprayers with a couple of nozzles to large, more complicated, self-propelled agricultural sprayers with a boom that might span over 100 feet.

How Does a Boom Sprayer Work?

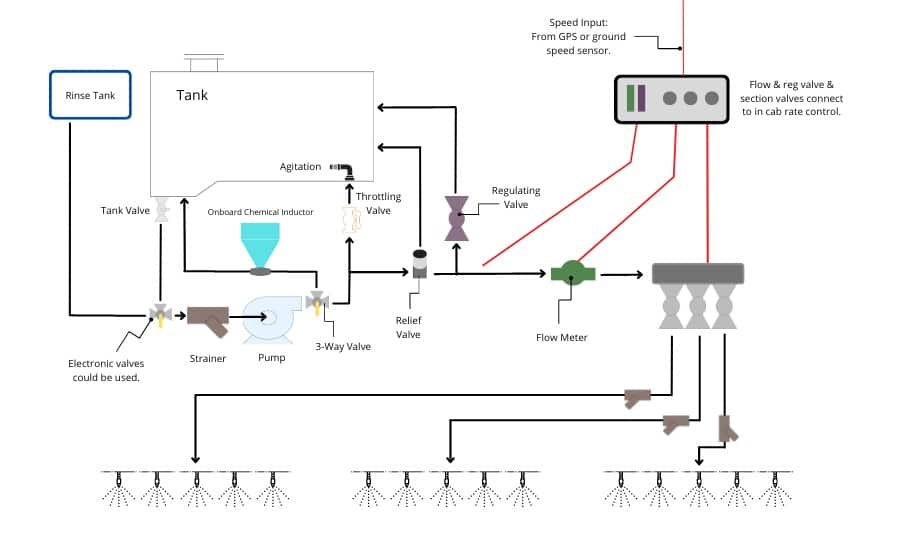

The basic function of a boom sprayer is essentially the same as any other sprayer. However, some boom sprayers tend to have more complex controls than other sprayer types. This is due to the myriad of different spray applications that a boom sprayer can handle.

Some of the optional features are individual control of boom sections, automatic rate control, as well as agitation and rinse features. These advanced controls are found on sprayers used for production agriculture and municipal anti/de-ice but they can be applied to almost any application.

Many applications do not require all these extra controls and capabilities. For scenarios like residential lawn care, professional turf management, dust control, etc., such sophisticated equipment is often not necessary.

Parts of a Boom Sprayer

In addition to the spray boom, there are several other components that comprise a boom sprayer:

- Pump

- Tank

- Hoses

- Controls

- Boom

- Nozzles

Boom Sprayer Diagrams

Large Complex Boom Sprayer

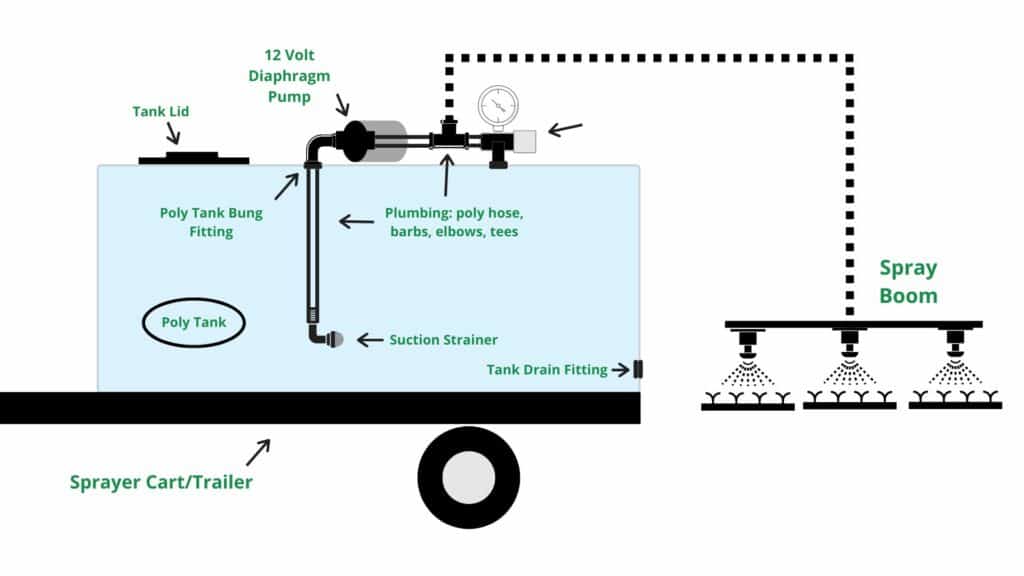

Simple Small Boom Sprayer

Boom Sprayer Pumps

Many different pump types can be used on a boom sprayer. However, the three most common types are 12-volt diaphragm, roller, and centrifugal pumps.

12-Volt Pumps

are used on smaller boom sprayers that don’t have high flow requirements such as ATV sprayers and pull-behind lawn sprayers. They can be powered by the existing battery on mowers, ATVs, pickups, etc.

Related: Troubleshooting a 12-Volt Sprayer Pump

Roller Pumps

When you need more flow and pressure than a 12-volt pump can provide, a roller pump is a practical option. When used on boom sprayers roller pumps are typically PTO driven. When a PTO is not available, roller pumps can easily be driven by a gas engine. They are primarily used on three-point sprayers on tractors. They are also used on skid sprayers but we will cover more about that in a different article.

Roller pumps are positive displacement pumps which means they can develop more pressure than centrifugal pumps but they require a bypass on the boom shut-off pressure will continue to build and damage hoses or other plumbing.

Centrifugal Pumps

Centrifugal pumps do come in different sizes but they generally produce much higher flow rates than the other two types of pumps mentioned above. They can be driven by PTO, a hydraulic motor, a gas engine, or an electric motor.

Centrifugal pumps can be used on any size sprayer, but because of the greater cost and need for more horsepower to drive them, they are typically used for applications that require such high flow rates. Generally, larger agricultural sprayers and de-icing sprayers will need a centrifugal pump in order to be effective.

Related: Troubleshooting Centrifugal Pumps & How to Size a Sprayer Pump

Sprayer Tank

The tank on a boom sprayer is one component that can vary greatly between different sprayers. There are so many different sizes and shapes of tanks used on sprayers. The tank on the sprayer may not seem like a big deal but there are several features and design factors that play a role in the function and performance of a boom sprayer.

The most common type of sprayer tank used today is it polyethylene tank. This type of tank has good chemical resistance and strength, plus it is lightweight. Making it ideal for use on boom sprayers.

Tank shape

Tank shape may seem arbitrary, but it serves a purpose. There are many reasons for the differences in tank shape. The shape will affect how the tank drains, where it can fit, it’s center of gravity, and more. It is difficult to describe the different sprayer tank shapes, so let’s look at some examples of how the shape of your tank can impact your sprayer.

The tank above is a common style used for small ATV/UTV turf sprayers. The benefit of this tank is the low profile design that fits easily on the back of an ATV and has a low chance of rollover. One drawback is that the bottom of the tank is uneven and does not slope to a single spot. This makes it hard to drain out completely.

This tank is completely round. This means that as the liquid level drops, it is forced to the drain port on the tank.

Tank size

The bigger the tank the more area that can be covered without having to reload your sprayer. Of course, this will also make your loaded sprayer much heavier and limit what piece of equipment can pull it. This is particularly important when selecting a sprayer for a 3-point on a tractor. 3-point hitches will have a limit to the weight they can handle. Below are some common sprayer tank sizes for different sprayer types, along with the approximate weight of those sprayers when fully loaded.

| Sprayer Type | Common Tank Sizes (Gallons) | *Approximate Loaded Weight of Tank (lbs) |

|---|---|---|

| Mowers | 5-25 | 40-200 |

| ATV | 15-25 | 125-200 |

| UTV | 50-100 | 400-800 |

| Pickup | 50-200 | 400-1600 |

| Tractor 3-Point (Cat 1) | 50-150 | 400-1200 |

| Tractor 3-Point (Cat 2) | 100-300 | 800-2400 |

Sprayer Tank Features

In addition to the size and shape of your sprayer tank, there are multiple features that tanks can have. Lid type, baffles, sumps, UV inhibitors, and more.

A larger tank lid will make it easier for you to clean out your sprayer or access anything that may get stuck inside. If you want a large sprayer for the back of a truck, you should consider a tank with baffles. This will help reduce the chances your truck would roll because of the liquid “sloshing” about in the tank.

A tank with a sump will provide a more complete drain out, than a tank with a flat bottom. A sump is a recessed and molded area on the bottom of the tank that slopes to the drain.

Most poly tanks will have UV inhibitors that help reduce the degradation from sunlight over time. This will make your sprayer tank last much longer, so be sure to check that the sprayer you buy has a tank with UV protection built in.

Boom

Obviously, you can’t discuss it boom sprayer, and not talk about the boom. As we’ve previously discussed there are different types of booms.

Conventional Boom

A conventional boom is the type that is most commonly associated with a standard boom sprayer. This is made up of several nozzles evenly spaced along a piece of pipe or bar. There are two types of conventional boom: wet and dry. The difference is in the way the nozzle bodies are mounted and the liquid is supplied to the boom. For a detailed explanation of the differences refer to this post on wet vs dry spray booms.

Boomless Sprayers

A “boomless” sprayer is closely related to the boom sprayer. This type of sprayer will cover a wide swath like a boom sprayer but instead of several nozzles spaced evenly on the boom, it uses just one single nozzle or two nozzles mounted back to back. These nozzles are designed to cover a lot of ground. They spray directly down just like a flat fan nozzle but they also spray out to the side up to 15-20 ft depending on the nozzle.

There is a lot more information about this type of sprayer and that is why I wrote an article specifically covering all aspects of boomless sprayers.

Nozzles

I say this a lot but that’s because I believe it to be true: the nozzles are the most important part of your spray regardless of the type of sprayer. That being said it is important to consider the type of sprayer nozzle you will use.

Many boom sprayers designed for lawnmowers, ATVs, UTVs, etc., will come with a “standard” set of spray nozzles. It should not be assumed that these nozzles are the best option for your application. Selecting a nozzle is important to ensure you are applying the correct rate, and doing it in an effective, and efficient manner.

Related: Is There a Standard Sprayer Nozzle?

Some pesticides require a specific nozzle type or they may drift from the target area. Also, a failure to properly size your nozzles will result in under or over-applying your liquid. If you are new to spraying, be sure to read this post where I cover in detail how to select a sprayer nozzle for a boom sprayer.

Boom Sprayer Controls

There are several methods to control the output of a boom sprayer. Smaller lawn sprayers will have a pressure regulating valve and that is about it, while larger sprayers for agriculture or de-ice might have more complicated electronic controls to regulate the sprayer output and make adjustments remotely as you spray.

You can read more detailed information in this article about sprayer control options.

Pressure vs Flow Meter Controls

There are two basic sprayer control types, pressure, and flow meter control. Pressure-based controls allow the user to make adjustments to the output of the sprayer based on the operating pressure. This can be achieved in a number of ways.

The simplest way is a pressure gauge and a manual regulating or bypass valve. The valve can be adjusted by the user to increase or decrease pressure as needed. This requires you to calculate ahead of time what your output is at different pressures, then identify what speed you need to travel to maintain your desired rate.

If you are new to spraying, this can be confusing. These articles can provide more information on sprayer application rates and calibrating your sprayer:

More complex pressure control systems have remote electronic controls. This gives the user the ability to make adjustments to the sprayer output from a tractor cab or seat of a UTV, etc. This type of system requires a pressure sensor, rate controller, and electronic regulating valve.

Flow meter-based sprayer control provides the user with a precise reading of the output of the sprayer measured in gallons per minute or liters per minute. The flow meter communicates to a rate control computer and displays this in the cab. This allows the user to make adjustments based on the reading of the flow meter.

Advanced rate controllers will make adjustments automatically based on the flow meter readings, and the inputs provided by a user. The user inputs the desired application rate, spray nozzle spacing on the boom, and spray nozzle size (flow capacity). Automatic rate control requires a regulating valve and a speed input of some kind, either GPS or wheel/ground speed sensor.

The Flow meter, regulating valve, and speed sensor all communicate with the rate controller to maintain the target application rate. The rate controller tells the regulating valve to open or close to provide the necessary amount of flow to achieve the target application rate as the sprayer changes speed.

This is a complex topic that warrants further explanation beyond what is in this article. Therefore if you are interested in learning more, this article on sprayer rate control types provides more details.

Different Types of Boom Sprayers

Pull-Type

Many Boom sprayers Are designed to be towed behind a tractor, mower, ATV, or other pieces of equipment. Photo sprayers are available in many different sizes ranging from small sprayers pull behind mowers to large crop sprayers. From 25 gallons of too well over 1000 gallons. If you have a lawn tractor a pull-type boom sprayer is a good option assuming you have lots of space to turn around and not a lot of obstacles.

ATV/UTV

With all the different types of ATVs and new UTVs available today there are many sprayers designed to fit in these types of vehicles. One advantage of this style is its tighter turning radius. You also may find that a UTV/ATV sprayer is less expensive when compared to a pull-behind sprayer of equal size because there is no need for running gear, frames, or wheels.

3-Point

Three-point boom sprayers are made to fit on a three-point hitch of a tractor. Just like the other types these are available in several different sizes. They typically range from about 100 to 500 gallons. As with a UTV sprayer you may save a little money for a comparable sprayer because there is no need for wheels.

How to Use a Boom Sprayer

Although using a boom sprayer is straightforward, calibrating the sprayer so that you are applying the correct amount and making sure that you are covering your area with no gaps or excessive overlap or not.

If you are just starting out using a sprayer, these resources can help you to calibrate and operate your sprayer: