Every industry has its own jargon. If you are a novice you may find yourself confused when a more someone experienced in that field is explaining something to you. When it comes to lawn and turf sprayers, this is no different. So here are 23 terms and phrases that you probably have heard but may not know what they mean if you are a beginner.

Common Sprayer Terms

GPM

Abbreviation of gallons per minute. Gallons per minute is used when referring to the rate of flow coming out of your sprayer. It is also used to indicate the flow capacity of a sprayer nozzle. Example: 0.4 GPM at 40 psi.

If you are new to sprayers and spray nozzles, then you should definitely read this article that answers several common questions regarding sprayer nozzles.

Manifold Flange

A plumbing connection that is commonly used in agricultural spraying. Two flange ends are held together with a clamp and sealed with a gasket. You can find a detailed explanation and diagram in this post about the different manifold flange sizes.

Mechanical Seal

A mechanical seal is a mechanism designed to keep fluid from leaking out around the drive shaft of a pump. The mechanical seal has two faces that rub together as the shaft turns, the spring holds the faces tight against one another and prevents leaks.

In this article about troubleshooting a pump, you will find more information about mechanical seals and how they work.

Nozzle Body

A nozzle body is a piece on a spray boom. It is designed to hold the spray nozzle. Typically this is done by some “cap” or “nut” threaded onto the nozzle body. There are several different designs.

You can see some great information and images in this article on “wet” vs “dry” boom nozzle bodies.

Nozzle Body Thread

A standard thread type that is used on sprayer nozzle bodies and many spray wands. Also known as 11/16th-inch nozzle body thread or sometimes referred to as Teejet thread.

For a good guide to nozzle body thread, check out this article where I show in detail the thread and connections on spray wands.

Boomless Nozzle

A sprayer tip that is designed to cover a wide swath, replacing the need for a boom with multiple nozzles. There are several different boomless nozzle patterns and flow capacities. You can find more information in this article on the difference between a boom and boomless sprayer.

You can also see detailed examples of the different types of boomless nozzles in this article about selecting the best boomless nozzle.

Cam-Lever Coupling

A style of quick connecting fittings used in agricultural and industrial liquid handling applications. Available in many types and materials. Also known as cam-locks, lever couplings, quick couplers, and cam & groove couplers. Be sure to read this full guide on cam-lever couplings for more information.

EPDM

Ethylene Propylene Diene Monomer. A rubber material that is used to make hoses, O-rings, and gaskets. Recommended for use with many common agricultural herbicides/chemicals. Not recommended for use with fuels/oils.

Viton

Viton is a material with good chemical resistance. Gaskets, o-rings, and seals for sprayers and sprayer components are often made from Viton due to the wide range of chemical compatibility.

GPA

Abbreviation for gallons per acre. Gallons per acre is a way to measure the application rate of a sprayer. It refers to the total volume of sprayer output per acre. For a hand sprayer or spot sprayer, GPA is hard to determine because of the sporadic nature of the application. On a boom sprayer GPA is determined by the sprayer operating pressure, nozzle size, speed, and nozzle spacing.

Application Rate

The application rate is the amount of spray solution being applied over a certain area. Usually expressed in gallons per acre in agriculture and when spraying large areas. May also be displayed in other forms such as gallons per 1000 square feet, ounces per acre, gallons per lane mile, etc.

Different spray applications will use different units of measurement for application rate. Rates for small lawns will be different than for large pastures. Rates for spraying de-ice on roads will use gallons per lane mile. Application rates when spraying large farms are usually in gallons per acre.

Related:

Rate Controller

A rate controller is a device that is used to monitor, set, and make adjustments to the output of a sprayer. There are several different types with varying degrees of complexity. There are both manual and automatic rate controllers. Automatic rate controllers are capable of increasing or decreasing the output of a sprayer automatically.

For anyone looking for more information on sprayer rate control, be sure to read this article where I cover all the components of a simple sprayer rate control setup.

Flow Meter

A flow meter measures the rate at which liquid is traveling through it and/or the total amount of liquid that has passed through it. On a sprayer, the flow meter measures the rate of flow and communicates this information to the rate controller. Based on the input from the flow meter, the rate controller then adjusts the regulating valve accordingly to maintain the rate set by the operator.

Related:

Electronic Regulating Valve

When speaking in terms of sprayers, an electronic regulating valve is used to control the output of the sprayer. Onboard a sprayer a regulating valve is often a motorized ball valve. The electronic motor rotates the ball to incrementally open or close the fluid path, thus increasing or decreasing the flow rate.

The regulating valve can be controlled manually by the sprayer operator with a switch, or automatically by a rate control console. Rate control requires multiple components working together. I wrote an entire article to help beginners understand how to set up a simple electronic control for a sprayer.

Pressure Regulating Valve

Pressure-regulating valves are used on sprayers to adjust the pressure. On small spot sprayers and boom sprayers, manual regulating valves are adjusted by hand to increase or decrease pressure. Usually, they are accompanied by a pressure gauge.

The regulating valve is plumbed into the main fluid line on the sprayer via a “T” fitting. If the pressure in the line reaches the set pressure on the regulating valve, the regulating valve will open and allow liquid to be bypassed back to the sprayer tank.

See this article on sprayer plumbing to see where and how to install a regulating valve.

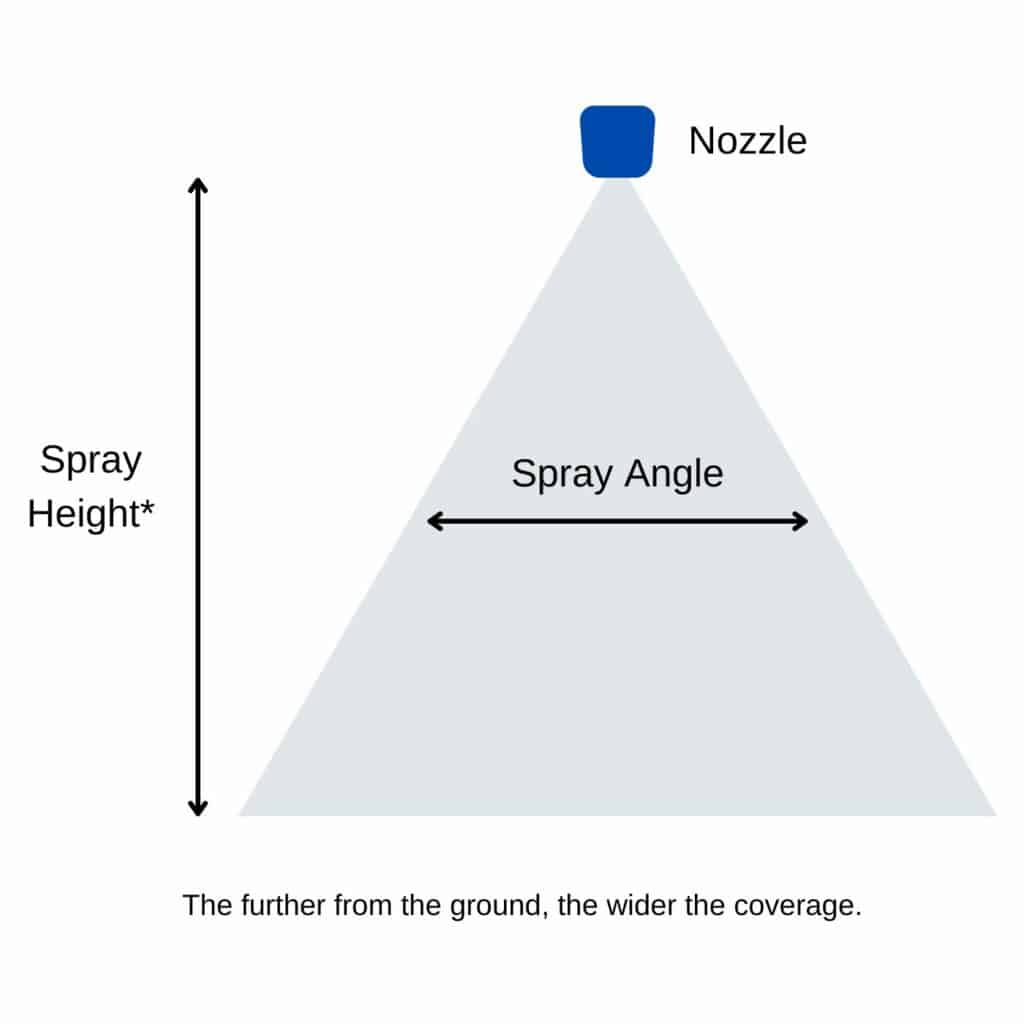

Spray pattern

The way in which liquid exits a sprayer nozzle. The shape, angle, and droplet size are the main aspects of the spray pattern. For more information about spray patterns, be sure to read this article about sprayer nozzles.

Droplet size

The size of the droplets produced by a sprayer nozzle. Droplet size is measured in Microns. Different sprayer nozzles are classified by the droplet size they produce. If you are not familiar with sprayer nozzles this article about sprayer nozzles explains droplet size in more detail.

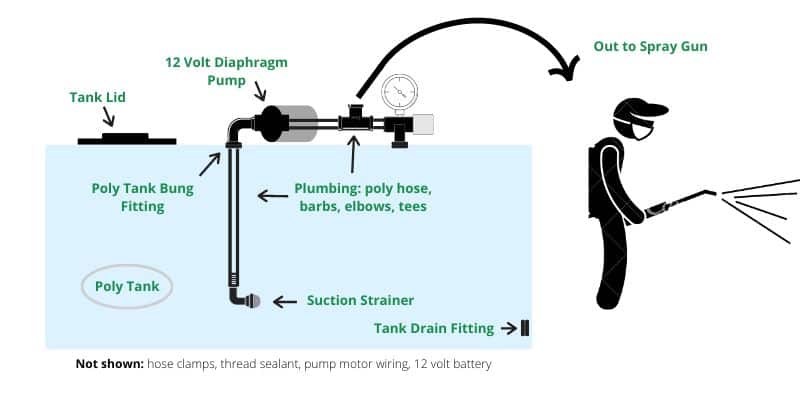

Trigger Gun

A trigger gun is a tool on a spot sprayer used to apply the liquid. It serves as the valve to shut off the sprayer when the trigger is not pulled. There are several versions, many include a wand, and the trigger gun contains a spray nozzle at the end of the wand. A trigger gun is also known as a spray gun, or spray wand.

Suction Hose

A suction hose is a reinforced hose that is used on the inlet side of a pump. A suction hose is made to withstand the vacuum created by a sprayer pump and not collapse.

Tank Sump

A sump is an area in the bottom of the tank where the drain fitting is located. The sump is the lowest area of the tank and generally, the walls and shape of the tank slope to the slump. The goal of a sump is to provide a more complete drain out of the tank. See the examples of different sumps below.

Bulkhead Fitting

A bulkhead fitting serves as an outlet port on a tank. There are different styles, but typically it consists of three pieces. A piece that fits inside the tank and sticks through the wall, a gasket, and a nut on the outside of the tank. The nut tightens the inside piece in place and the gasket provides a seal. There are also bolted styles, and bulkhead fittings can be made from many different materials.

Skid Sprayer

A skid sprayer is any sprayer that is made to fit into the bed of a UTV, truck, or trailer. Named for the “skid” the sprayer is mounted on. Typically used for tree spraying, spot spraying, and fire control.

Spot Sprayer

A spot sprayer is designed to apply pesticides, cleaners, fertilizer, or some other to specific areas by hand. Often used in weed control applications. The operator uses a trigger gun to apply spray solution where it is needed. Want to know more? Check out the complete spot sprayer guide.

Sprayer Reach

Spray reach refers to how far your sprayer can “throw” liquid. Applicable to spot sprayers, skid sprayers, or any other type of sprayer where the operator is using a spray gun to direct a stream of liquid. Spray reach could also be called sprayer throw, spray distance, etc.

The reach of a sprayer is dependent on many factors. The pressure and volume the sprayer can produce as well as the nozzle size and type of spray gun used. You can refer to this article about tree sprayers to see what types of sprayers can spray far distances.