Here at sprayer guru, we consider a sprayer to be a fascinating machine made up of ingenious components. However, we do recognize that not everyone is as nerdy about spray equipment and We could hardly call ourselves a sprayer website if we did not thoroughly explain the ins and outs of how a sprayer operates.

So if you’re looking to understand how your sprayer works, so you can resolve any issues, or are just curious, this is the web page for you. Now let’s get to the business of explaining how the sprayer operates.

Working Principles of Sprayers

When it comes to understanding the inner workings of a sprayer, grasping the working principles is crucial. The journey of the liquid through the sprayer is governed by the principles of fluid dynamics.

The rate at which the liquid flows and its consistency in terms of spray are influenced by several factors. These include the type of pump used, the diameter of the hoses, and the other controls (valves) in place.

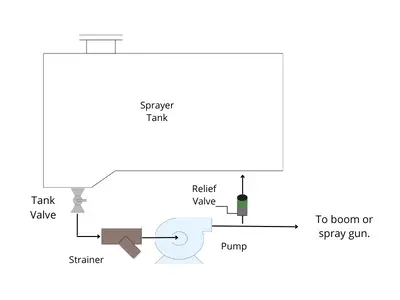

In simple terms, a sprayer works by using a pump to transfer liquid through the system and disperse it through the sprayer boom or spray gun. Of course, on most sprayers, things tend to be more complicated than this.

There are many different types of pumps, valves, hoses, tanks, fittings, and other components. Depending on the needs of the user, different components will be required to achieve the necessary flow and pressure to achieve the desired results.

For example, two sprayers have the same size sprayer boom, pump, and tank, but if one has manual boom and pressure control while the other has electronic boom and pressure controls, this will result in a large disparity in convenience and efficiency for the user.

Not only do the specific components affect the sprayer, but also the way that they are incorporated together through the spray plumbing plays a huge role in the functionality of the sprayer. To put it simply: changing the plumbing will change the features and functions of the sprayer.

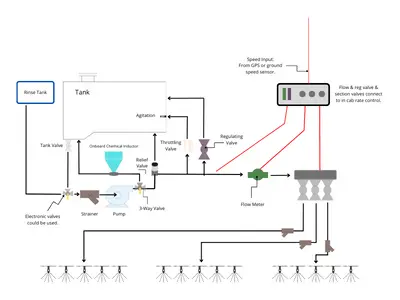

Let’s look at these two small sprayers. They have the same tank size, and same pump, and generally appear very similar. The sprayer on the right has a much more elaborate plumbing setup that incorporates automatic rate control, section control, a mixing tank, and a rinse tank.

So, as you can see, changing the plumbing can affect the performance and capabilities of a sprayer. If you want to see detailed plumbing guides for different types of sprayers as well as a full list of the various sprayer components, then be sure to look at this article with multiple sprayer plumbing layouts.

Another major aspect of a sprayer is the pump. Changing the pump changes the maximum flow rate and/or the maximum pressure of the sprayer. Different pump types are used in different applications. Centrifugal pumps are common in high-flow scenarios such as large-scale farming. Diaphragm pumps produce much higher pressure, they are often used on tree sprayers.

There are many different types of sprayer pumps, and in this article, we are not going to discuss all of them or we would be here all day. Instead, if you want to know the details of each pump type, then take a look at the article I wrote that breaks down the different sprayer pumps and their uses.

Now to best get an understanding of how all the pieces of a sprayer work together Let’s consider the path that the liquid takes through the sprayer and how each component works together.

The Sprayer Tank

Everything starts with the sprayer tank. The tank is the storage for whatever fluid or mixture you intend to spray. But while it might seem like there’s not much to say about a sprayer tank, there can be several differences between seemingly similar tanks. There are also many features built into tanks that you may not have considered.

Sprayer Pump

Now back to business, when the Liquid leaves the tank it heads into the sprayer pump. Liquid is often gravity-fed to the inlet of the sprayer pump. This means that a pump is below the liquid level in the tank at all times. But some sprayers do have self-priming pumps. A self-priming pump can draw liquid up and out of the tank.

| Self-Priming Pumps: | Non-Self Priming Pumps: |

| Roller Pumps Diaphragm Pumps Self-Priming Centrifugal Pumps | Straight Centrifugal Pumps |

The pump is the centerpiece of a boom sprayer and its ability to generate flow and pressure. Common pump types used on sprayers are centrifugal, diaphragm, piston, and roller pumps. Each operates using a unique manner, but the goal remains the same: to propel the liquid (pesticides, herbicides, or fertilizers) through the system.

For more details on the different types of sprayer pumps visit our comprehensive guide on Choosing the Right Pump for Your Sprayer.

You can also read this guide on how to size a sprayer pump.

The pressure must be consistent to ensure that the rate at which the liquid is dispersed out of the nozzles is constant. This consistent pressure is what allows for an even application across an entire field. This is critical for effective results.

Sprayer Controls

Another important aspect is controlling the flow of liquid. Applying different pesticides and fertilizers typically needs to be done accurately. A sprayer needs some mechanism for the operator to control the flow rate otherwise there is no way to know how much liquid is being applied. This can result in damage to lawns and crops or if not enough applied the active Pesticide herbicide fertilizer etc. won’t be effective. Furthermore, a regular application will result in streaky or spotty results.

The level of precision required depends upon the application. If you are a homeowner spraying your lawn you want an even application but the level of precision is likely not the same that is needed in large-scale agriculture.

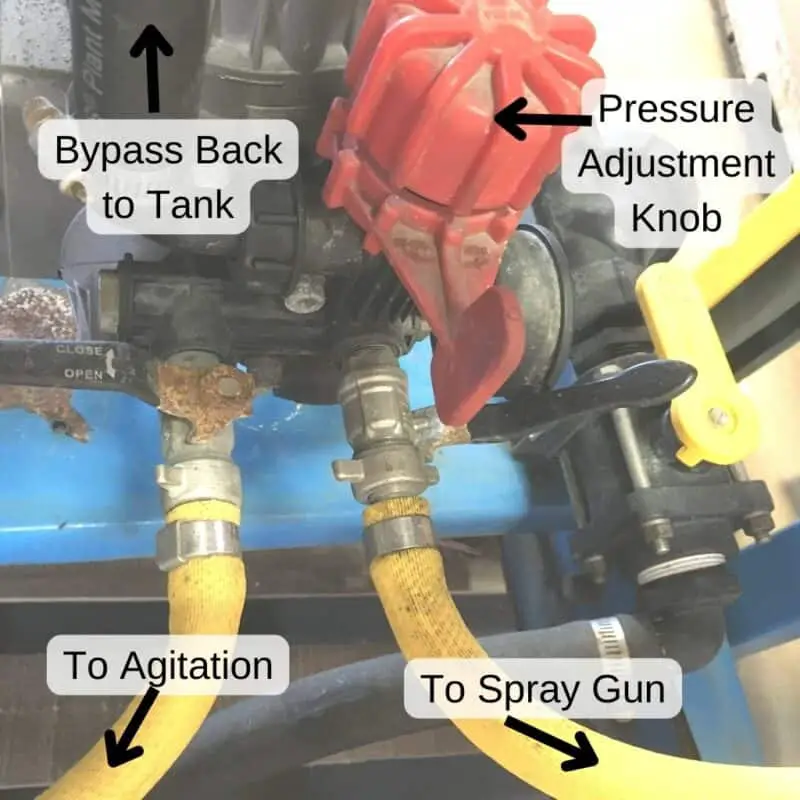

A simple manual regulating valve is often what is used to control the operating pressure yes maintain the same amount of fluid dispersed from the nozzle over a given amount of time.

Farmers need to be more precise when they mix and apply different chemicals to limit waste and maximize yield. Profit margins can be slim so every ounce matters.

This necessitates more advanced controls. Usually, electronic regulating valves, flow meters, GPS guidance, and a rate control computer are used to accurately monitor and adjust the sprayer’s output as needed to ensure consistency and even application.

This automatic rate control system is elaborate and if you want to know more about the specific details of the flow meters, valves, sensors, etc. that go into this makeup please check out this article that explains electronic sprayer controls.

Sprayer Manifold

Directing fluid is a necessity for any sprayer, whether it is a small turf sprayer or a larger agricultural sprayer. When fluid leaves the pump it will typically head to the manifold of some kind where it can be split up and directed where the operator desires.

Valves are used to control the outlets on the manifold. The size and scope of the manifold depend on the sprayer type. From the manifold liquid to be directed to a spray boom, or section of a sprayer boom (more on this below). Give me directions to an agitation chat in the tank, the spray gun, or another accessory on the sprayer such as rinsing nozzles inside the tank or to the inductor tank.

A regulating valve can be incorporated into the manifold or operating pressure is controlled excess liquid bypass back to the tank.

Manifold Examples:

Sprayer Boom

The goal of a sprayer is to disperse liquid evenly over a wide area. The main apparatus that is used to achieve this is a spray boom. While sprayer booms come in a variety of different sizes and designs, their function and purpose remain the same.

Structure and Design:

- A sprayer boom typically consists of a horizontal bar or series of bars extending from the sprayer unit.

- They come in various lengths, ranging from a few feet for smaller, more portable units, to 120 feet or more for large agricultural equipment.

- The boom can be made of steel, aluminum, stainless, poly, or whatever is strong enough for the application but lightweight enough for the equipment being used to pull it/carry it

- Larger booms are often equipped with hydraulic cylinders or shocks to absorb tension and help level the boom as the sprayer passes over rough terrain

Different Sprayer Boom Characteristics

There are two primary types of sprayer boom designs: “wet” booms and “dry” booms. You can see a complete explanation of the two in this article comparing “wet” and “dry” booms.

The difference between these two boom types is how the liquid is carried on the boom. A “wet” boom has a solid pipe to carry the liquid while a “dry” boom uses hoses.

Nozzle Bodies: Booms have several nozzle bodies spaced at regular intervals. A “nozzle body” is a component that attaches to the boom. The nozzle is either threaded onto the body or held on with a cap. Liquid from the boom pipe or boom hoses flows into the nozzle body and then out the spray nozzles.

Connecting spray tips to different types of nozzle bodies and spray bombs can get complicated. There are so many different types of sprayer tips and brands of sprayers. This guide provides a detailed look at how to connect an adapt sprayer nozzles.

Height Adjustment: Many sprayer booms allow for height adjustment. This feature is important because the height of the boom above the target area can significantly affect the spray coverage and drift. Adjusting the height helps in optimizing the application for different crops or plants.

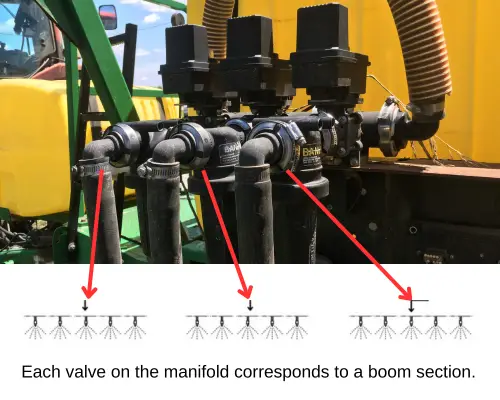

Boom Sections: A sprayer boom is often divided into several independent sections, known as boom sections. These sections can be controlled separately, allowing the operator to turn on or off specific parts of the boom. The division into sections helps in minimizing over-application and chemical wastage, especially important when turning at the end of rows or when spraying areas of irregular shape.

Typically, larger booms have more sections. The number of sections can vary depending on the size and sophistication of the sprayer. Each section usually spans several feet and contains multiple nozzles. Controlling boom sections is done via a section manifold with an electronic valve that corresponds to each boom section.

Sprayer Nozzles

Lastly, the spray distribution, a critical aspect of boom sprayers, hinges largely on the type and setting of the nozzles. Nozzles determine the pattern and size of the droplets being sprayed. In agricultural boom sprayers, achieving uniform distribution over wide areas is vital to ensure that every part of the crop receives the necessary treatment.

Different nozzle types, such as fan, cone, and flood jet, are used based on the specific application requirement. For instance, a fan nozzle might be preferred for broad, even coverage, while a cone nozzle may be more suitable for targeted applications. The correct alignment and spacing of these nozzles on the boom also play a significant role in achieving the desired spray coverage.

To explore nozzle types and their applications further, check out our detailed article on Selecting the Right Nozzle for Your Sprayer.

Different Types of Sprayers

No matter the type of sprayer, the basic function is the same. This article is focused mainly on boom sprayers, but if you want to see a list of several different types of sprayers then be sure to read this guide on the different sprayer types and their uses.

- Crop sprayers

- Self-propelled sprayers

- Pest control spray rigs

- Lawn sprayers

- Tree sprayers

- De-Ice sprayers

- Dust control sprayers

- Concrete/Driveway Sealing Sprayers

- Right of way sprayers

- 3-point mounted sprayers

- Pull-type sprayers

Difference Sprayer Features and Accessories

The function and capability of a sprayer can vary greatly. Sprayers can be equipped with several different features based on the user’s preferences and needs. Here are some common sprayer features:

- Height Adjustment: Many boom sprayers allow for height adjustment of the boom. This is crucial for maintaining the correct distance between the nozzles and the target, which affects spray coverage and drift.

- Auto-Leveling Systems: Advanced sprayers might have auto-leveling systems that maintain a constant height above the ground or crop canopy, ensuring even application and minimizing drift.

- Section Control: This feature allows operators to turn off sections of the boom, which is particularly useful to avoid over-spraying in areas where the field overlaps or when spraying around obstacles.

- Rate Control: Modern boom sprayers often have sophisticated rate control systems that can adjust the flow rate based on the speed of the sprayer, ensuring a consistent application rate across the field.

- GPS and Guidance Systems: Some high-end models are equipped with GPS technology for precise mapping and guidance, which can improve efficiency and reduce overlap during spraying.

- Chemical Injection Systems: These systems allow for the mixing of chemicals on the fly, reducing the need for pre-mixing and allowing for quick changes between different chemicals.

- Foam Markers: Foam markers at the ends of the boom release a small amount of foam to mark the edge of the sprayed area, helping to avoid overlapping passes and ensure even coverage.

- Suspension Systems: To reduce the impact of uneven terrain, some boom sprayers are equipped with suspension systems. This feature is particularly important for maintaining nozzle height and spray pattern in rough field conditions.

- Foldable Booms: For ease of transport and storage, many booms are designed to fold. Larger booms especially benefit from this feature, as it makes them more maneuverable in tight spaces.

- Breakaway Sections: To prevent damage, some booms have breakaway sections that can fold back if they strike an obstacle, they return to their original position.

- Rinsing Systems: This feature is essential for cleaning the sprayer’s internal components, particularly after the application of pesticides or herbicides. A good rinsing system ensures that there is no cross-contamination between different chemicals and extends the life of the sprayer by preventing chemical residue build-up. Some advanced systems even allow for in-field rinsing, which is very efficient.

- Agitation Systems: An agitation system is crucial for keeping the spray mixture well-mixed and consistent. This is particularly important when using suspensions or water-soluble powders that might otherwise settle or separate. Agitators can be mechanical or hydraulic, and they ensure that the chemical concentration is uniform throughout the tank, leading to more effective and uniform application.

Final Thought

Although sprayers I’ll serve the same general purpose they vary in their complexity and size. Key to safely in fact play operating sprayers to understand the working principles, as well as the individual components, and how they work together.